To master bypass valves in a weekend, start by understanding their basic parts, functions, and the different types like ball, globe, and diaphragm valves. Learn how they operate in various systems such as heating, hydraulic, and filtration, and familiarize yourself with troubleshooting common issues like leaks or miscalibration. Practice testing and fine-tuning for peak performance using essential tools and safety precautions. Keep exploring, and you’ll quickly build confidence in managing these valves effectively.

Key Takeaways

- Study bypass valve components, types, and their functions to understand how they control flow and pressure.

- Learn troubleshooting techniques for common issues like leaks, sticking valves, and calibration errors.

- Practice using essential tools such as pressure gauges, wrenches, and calibration devices safely and effectively.

- Perform system tests to check flow rates, pressure regulation, and response times for real-world understanding.

- Review maintenance routines and fine-tuning methods to optimize valve performance and ensure safety.

Understanding the Basics of Bypass Valves

Bypass valves are essential components in many fluid systems, allowing you to control the flow of liquids or gases around certain sections of equipment. Understanding how they work requires a grasp of fluid dynamics, which explains how fluids move under different conditions. Proper valve calibration is critical to guarantee the bypass functions correctly, maintaining system efficiency and safety. When you adjust the valve, you’re fine-tuning its response to pressure changes, which directly impacts flow rates. If the valve isn’t calibrated properly, it can cause fluctuations or pressure buildup, affecting the entire system. Learning these basics helps you optimize performance, prevent damage, and troubleshoot issues effectively. Mastering the relationship between fluid dynamics and valve calibration is key to managing bypass valves confidently. Accurate calibration ensures the system operates smoothly and extends the lifespan of the equipment.

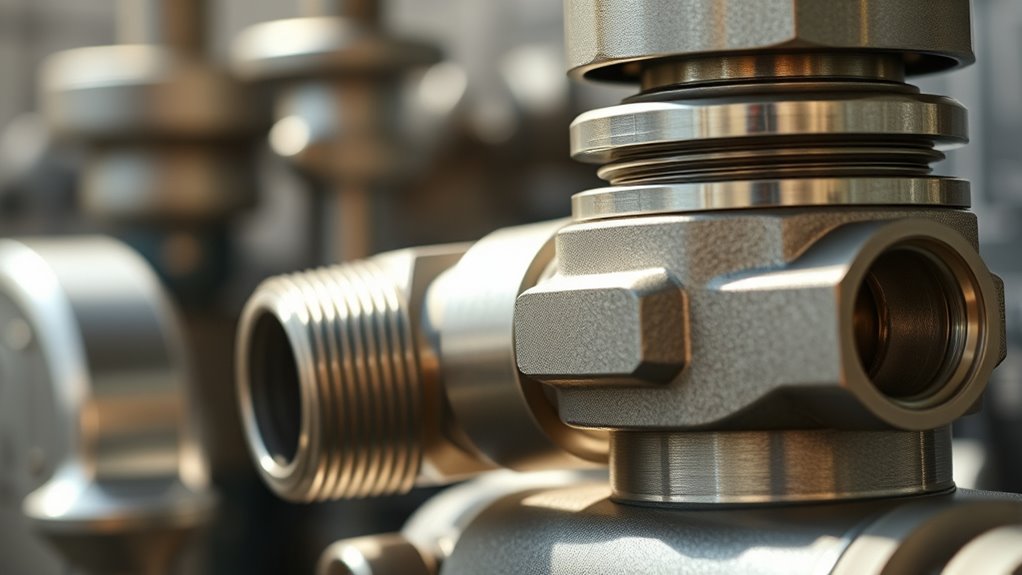

Key Components and Types of Bypass Valves

Understanding the key components of bypass valves helps you grasp how they control fluid flow effectively. The main parts include the valve body, seat, disc or plug, and actuator. These components work together to open or close the flow path as needed. Valve materials, such as stainless steel, bronze, or plastic, are chosen based on the application’s pressure, temperature, and fluid type, ensuring durability and corrosion resistance. Bypass valve history shows a progression from simple manual designs to sophisticated automatic models, reflecting advancements in materials and control mechanisms. Types of bypass valves vary, including ball, globe, and diaphragm styles, each suited for specific systems. Knowing these components and types helps you select and maintain the right bypass valve for your needs. Additionally, understanding common financial terms can aid in budgeting for system upgrades or maintenance, ensuring cost-effective operation.

How Bypass Valves Work in Different Systems

In various systems, bypass valves control fluid flow by redirecting or regulating pressure to maintain ideal operation. They achieve this through precise flow regulation, opening or closing as needed to divert fluid paths. In heating and cooling systems, bypass valves adjust pressure to prevent over-pressurization, ensuring consistent temperature control. In hydraulic systems, they regulate pressure to protect components from damage, allowing excess fluid to bypass critical parts. In filtration setups, bypass valves enable fluid to bypass clogged filters, maintaining system flow. By controlling how much fluid flows through or around specific parts, bypass valves help systems run smoothly and efficiently. Their ability to manage pressure and flow ensures stability, safety, and perfect performance across different applications. Additionally, understanding projector technology helps optimize system performance and safety.

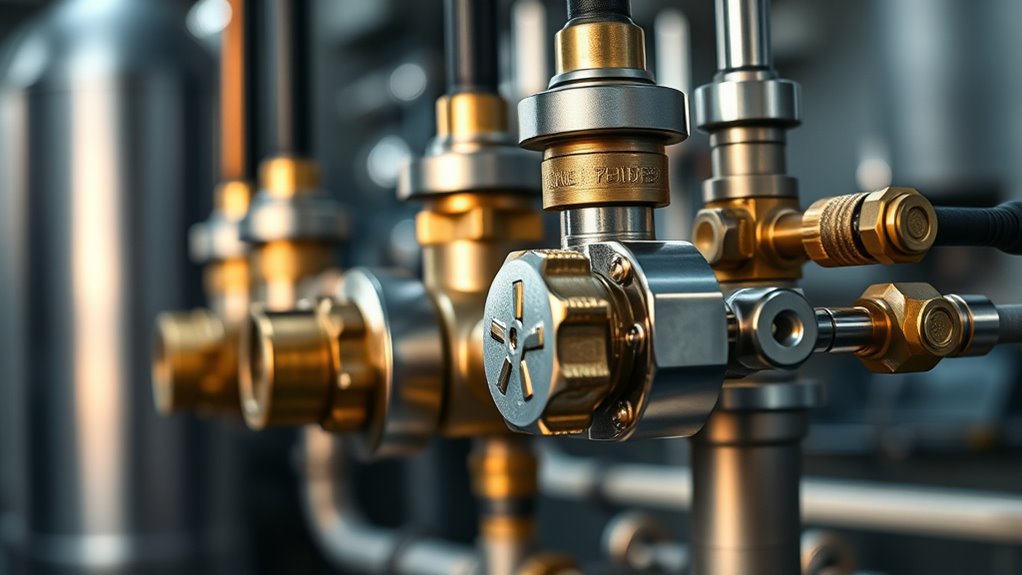

Essential Tools and Safety Precautions

When working with bypass valves, having the right tools and following safety precautions is vital to guarantee smooth and safe operation. You’ll need basic hand tools like wrenches, screwdrivers, and a pressure gauge to monitor fluid dynamics effectively. Always wear protective gear such as gloves and safety glasses to prevent injuries from high-pressure fluids or sudden valve releases. Understand that valve materials vary—metal, plastic, or composite—so choose the appropriate tools to prevent damage. Ensuring proper sealing and avoiding leaks is essential, especially since improper handling can disrupt fluid flow or damage the system. Before starting, double-check all connections and vent the system if necessary. Proper knowledge of Kia Tuning components can help prevent accidental damage during adjustments. Safety and precision are key to mastering bypass valves efficiently and avoiding costly mistakes.

Step-by-Step Guide to Installing a Bypass Valve

Installing a bypass valve requires careful preparation and precise steps to guarantee proper function. First, shut off the system and drain any residual fluid. Next, identify the correct mounting location, ensuring it allows for effective flow regulation. Disconnect the existing pipe or valve, then position the bypass valve in place. Secure it tightly using appropriate fittings, making sure there are no leaks. Once installed, proceed with valve calibration by adjusting the flow control settings to match system specifications. This ensures the bypass operates smoothly and maintains proper flow regulation. Double-check all connections and fittings before restarting the system. Proper installation and calibration are essential for the bypass valve to function correctly, providing reliable flow control and system efficiency. Understanding Soul Sanctuaries can help in selecting the right type of bypass valve for specific applications.

Common Troubleshooting Tips and Maintenance

To keep your bypass valve working smoothly, you need to recognize signs of failure early and perform regular maintenance. Understanding common issues can help you troubleshoot problems quickly and avoid costly repairs. Let’s explore key tips for spotting issues and keeping your bypass valve in top shape. Regular inspection of essential oils for maintenance can also help identify potential concerns before they escalate.

Recognizing Bypass Failures

Recognizing bypass failures is essential for maintaining system efficiency and preventing costly damage. If you notice inconsistent pressure regulation, it could indicate the bypass valve isn’t functioning correctly. A faulty bypass may cause fluctuations in flow control, leading to pressure surges or drops that disrupt system performance. Look for signs like unusual noises, leaks, or the valve remaining stuck in one position. A bypass that fails to open or close properly hampers proper flow control, risking equipment damage or reduced efficiency. Regularly inspecting the valve and its connections can help identify early signs of failure. Additionally, understanding flow control principles can assist in diagnosing issues before they escalate. Addressing these issues promptly ensures your bypass valve maintains ideal pressure regulation and flow control, keeping your system running smoothly and extending its lifespan.

Regular Maintenance Practices

Regular maintenance is key to ensuring your bypass valves stay in ideal condition and function properly. Consistent checks help maintain proper flow regulation and accurate valve calibration. To keep things running smoothly, regularly inspect for leaks, corrosion, and debris. Adjust calibration as needed to ensure the valve opens and closes correctly. Cleaning components prevents buildup that can hinder performance. Lubricate moving parts to reduce wear and prolong lifespan. Test the valve’s response under different flow conditions to confirm it operates as intended. Incorporating preventive maintenance strategies can further extend the lifespan of your valves and avoid costly repairs.

Troubleshooting Common Issues

When bypass valves encounter issues, quick identification and correction are essential to prevent system disruptions. Common problems often involve sensor calibration errors or irregular fluid flow. To troubleshoot, check if the sensor readings are accurate; miscalibration can cause incorrect bypass operations. Also, inspect for blockages or leaks that hinder fluid flow. Use the table below to visualize typical issues and solutions:

| Issue | Solution |

|---|---|

| Erratic bypass operation | Recalibrate the sensor |

| Low fluid flow | Clear blockages or leaks |

| Overly sensitive sensor | Adjust calibration settings |

| Stuck valve | Lubricate or replace valve components |

| System pressure issues | Check pressure regulators and valves |

Performing regular maintenance such as filter replacement every 6-12 months and inspecting components will help prevent these issues from occurring. Address these issues promptly to ensure your bypass valve functions smoothly, maintaining system efficiency.

Practical Tips for Testing and Optimizing Performance

To guarantee your bypass valve performs at its best, start with accurate testing procedures to identify any issues quickly. Fine-tuning the system can improve efficiency and prevent future problems. Keep these steps in mind as you assess and enhance your bypass valve’s performance. Engaging in dynamic communication exercises for couples can also help you better understand and address any underlying issues affecting system performance.

Testing Procedures for Accuracy

Are your bypass valves performing accurately? To ensure ideal pressure regulation and flow control, proper testing is essential. Start by checking the valve’s response to different pressure settings, observing if it opens and closes smoothly. Use a pressure gauge to verify the actual pressure matches the set point. Next, test flow control by measuring flow rates at various valve positions, ensuring consistent performance. Here are practical steps:

- Verify pressure regulation with a calibrated gauge

- Check for leaks or blockages

- Measure flow rates at different settings

- Record response times for valve operation

Fine-Tuning for Efficiency

Optimizing bypass valve performance requires ongoing adjustments based on your testing results. Focus on fine-tuning flow regulation to match your system’s needs, guaranteeing smooth operation without over-pressurization. Check compatibility with your system components to prevent leaks or malfunctions. Use these practical tips:

| Step | Action | Tip |

|---|---|---|

| 1 | Monitor flow rates | Adjust valve settings for ideal flow regulation |

| 2 | Test system response | Confirm compatibility with all components |

| 3 | Record adjustments | Track changes to refine performance over time |

Regular testing helps identify weak points and ensures your bypass valve maintains efficiency. Properly tuned, it enhances system longevity and performance.

Frequently Asked Questions

How Do I Select the Right Bypass Valve for My System?

To select the right bypass valve, consider your system’s pressure, flow rate, and compatibility with valve materials like stainless steel or brass for durability. You should also evaluate installation techniques to guarantee proper fit and function. Measure your system’s specifications carefully, and choose a valve that matches these requirements. Consulting manufacturer guidelines can help you pick the right materials and installation methods for seamless integration and peak performance.

What Are the Common Signs Indicating Bypass Valve Failure?

Your bypass valve acts like a vigilant gatekeeper—when it fails, you’ll notice issues like irregular system pressure, leaks, or strange noises that scream for attention. Regular maintenance routines and troubleshooting techniques help catch these signs early, preventing disaster. If your system suddenly dips in performance or you see unexpected bypass activity, it’s time to inspect the valve closely. Don’t ignore these symptoms—they’re the system’s way of whispering, “Help me!”

Can Bypass Valves Be Automated or Remote-Controlled?

Yes, bypass valves can be automated or remote-controlled. You can integrate remote control systems or automation options to operate them effectively, especially in complex setups. These systems allow you to adjust the valve settings remotely, providing greater convenience and precision. By installing automation options, you guarantee smoother operation, quicker response times, and improved system management without needing manual intervention, making your process more efficient and reliable.

What Are the Environmental Considerations When Installing Bypass Valves?

Have you considered how bypass valves impact the environment? When installing them, you need to assess their environmental impact, guaranteeing they don’t cause leaks or contamination. You also must prioritize regulatory compliance, following local laws on emissions and waste management. Proper installation and maintenance minimize environmental risks, helping you operate responsibly. Are you prepared to balance operational needs with protecting the environment? This awareness ensures sustainable and compliant valve management.

How Often Should Bypass Valves Be Inspected or Replaced?

You should inspect bypass valves regularly, typically following your maintenance schedule, which often suggests quarterly or biannual checks. Replace them if you notice signs of wear, corrosion, or if they no longer operate smoothly. Always consider material compatibility with the fluid and environment, ensuring the valve’s components withstand operating conditions. Regular inspections and timely replacements keep your system running efficiently and help prevent costly failures.

Conclusion

So, you’ve mastered bypass valves in a weekend—impressive, right? Just remember, even the best experts can’t outsmart a stubborn valve or a sneaky leak. Keep practicing, stay curious, and don’t get too comfortable; after all, the real challenge is resisting the urge to show off at your next maintenance gig. With your newfound knowledge, you’re now officially the boss of bypass valves—just don’t forget to keep a wrench handy for those “surprise” adventures.