Before tackling noisy pipes after making changes, guarantee you follow local plumbing codes and regulations. Check that all installations meet safety and quality standards, including proper pipe support, secure fittings, and correct slope. Verify your system maintains proper pressure and venting to prevent air pockets. Conduct thorough inspections and tests afterward. If you keep these steps in mind, you’ll reduce noise issues and stay compliant—plus, there’s more to discover on how to get it right.

Key Takeaways

- Review local plumbing codes to ensure planned modifications meet safety, efficiency, and compliance standards.

- Conduct a thorough inspection of pipe supports, insulation, and fittings before finalizing installation.

- Verify proper pipe slope, secure anchoring, and correct venting to prevent noise and system issues.

- Test water flow, pressure, and leak-tight connections post-installation to confirm system functionality.

- Consult licensed professionals to address potential code violations and ensure long-term, compliant, quiet operation.

Understanding Local Plumbing Regulations and Codes

Have you ever wondered why your plumbing system behaves differently after recent changes? Understanding local plumbing regulations is vital to ensure your modifications meet legal standards. These regulations, known as local plumbing codes, set the minimum requirements for safety, efficiency, and functionality. Failing to comply with code requirements can result in fines, mandatory repairs, or even the need to redo work. Before making any adjustments, it’s important to review your area’s plumbing code to confirm your plans align with local standards. Proper installation techniques, such as shower installation, are essential for preventing issues like noisy pipes caused by improper installation or incompatible materials. By prioritizing code compliance, you protect yourself from future problems, ensure the safety of your home, and avoid costly legal complications.

Assessing the Source of Noise in Your Plumbing System

When your plumbing starts making unexpected noises, pinpointing the source is essential to resolving the issue. Noises often come from pipes knocking, banging, or vibrating. Start by listening carefully to identify which pipes are affected. Check for loose pipe straps or inadequate pipe insulation, as these can amplify sound. Installing noise barriers or adding pipe insulation can reduce vibrations. To help you diagnose, consider this table:

| Noise Type | Possible Cause | Solution |

|---|---|---|

| Banging | Water hammer or loose pipes | Secure pipes, install water hammer arrestors |

| Rumbling | Sediment buildup or high flow | Flush system, adjust flow rate |

| Vibrations | Pipe contact with framing | Use pipe insulation or padding |

| Whistling | High pressure or loose fittings | Check pressure, tighten fittings |

Additionally, inspecting your system regularly can prevent noise issues from worsening, aligning with the importance of ongoing maintenance for plumbing systems.

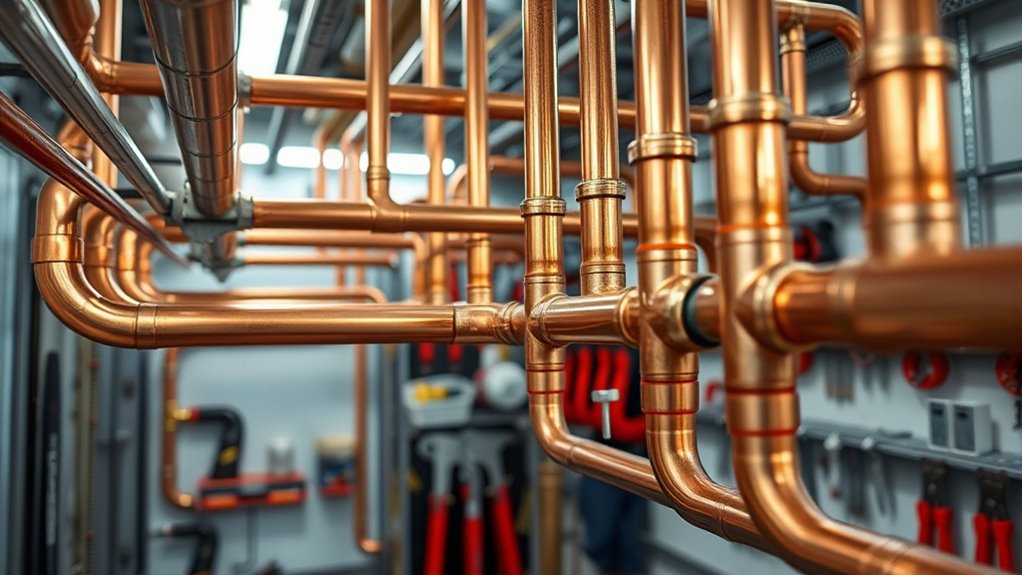

Ensuring Proper Pipe Support and Securing Techniques

Proper pipe support and securement are essential to preventing noise and damage in your plumbing system. Make sure pipes are firmly anchored using appropriate brackets and hangers, especially in areas prone to movement or vibration. Use pipe insulation around vulnerable sections to reduce noise caused by expansion and contraction. Vibration dampening mounts can also absorb shocks and minimize rattling sounds. Avoid loose fittings or unsupported runs, as they can cause pipes to vibrate and create noise. Regularly inspect support points and tighten or replace them as needed. Proper support not only diminishes noise but also prevents stress on joints, reducing the risk of leaks or breaks. Additionally, understanding Gold IRA options can help diversify your investment portfolio and secure your financial future. Clear support and vibration dampening techniques ensure a quieter, more durable plumbing system.

Selecting Appropriate Pipe Materials and Fittings

Choosing the right pipe materials and fittings affects both durability and noise levels in your plumbing system. You need materials that withstand wear and tear without amplifying sound. Additionally, make certain your fittings are compatible and flexible enough to prevent vibrations and rattling. Incorporating material durability considerations can further ensure long-lasting, quiet operation.

Material Durability and Noise

Selecting the right pipe materials and fittings is crucial for minimizing noise caused by vibrations and water flow. Durable materials help prevent expansion, contraction, and rattling that produce noise. To enhance noise dampening, consider these factors:

- Use materials like copper or PEX, which absorb vibrations better than rigid plastics.

- Incorporate pipe insulation to cushion the pipe, reducing noise transmission.

- Choose fittings designed for flexibility, which decrease stress and vibrations.

Proper material selection ensures longevity and reduces noise issues over time. Pipe insulation plays a key role in dampening sound, especially in areas prone to vibrations. By prioritizing durability and noise dampening, you minimize the chance of noisy pipes after changes and maintain a quieter, more comfortable environment.

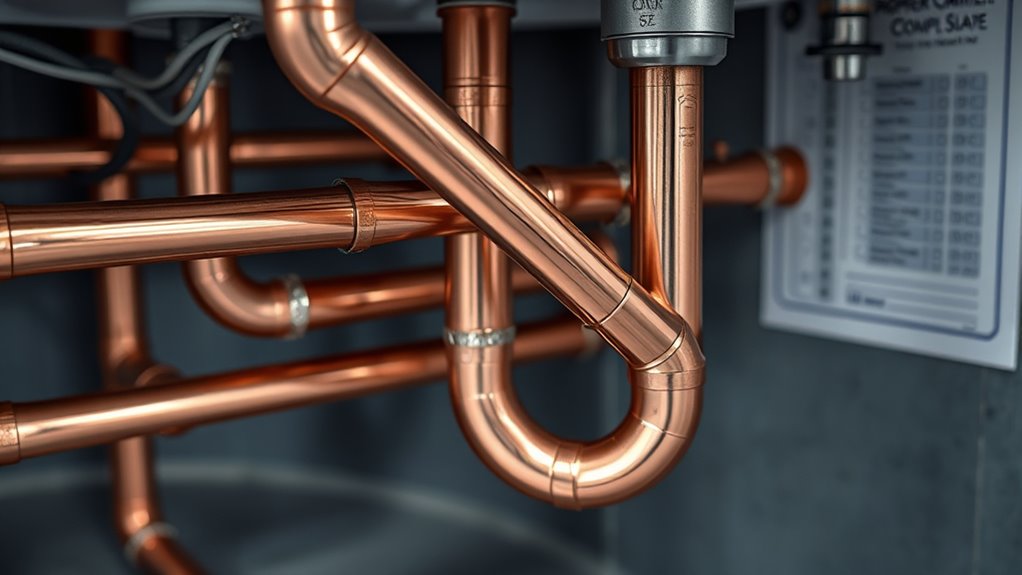

Fitting Compatibility and Flexibility

When it comes to minimizing noise and ensuring a secure connection, fitting compatibility and flexibility are essential considerations. You need to select fittings that match your pipe material to prevent leaks and reduce vibrations that cause noise. Fitting compatibility guarantees a proper seal, preventing water hammer and rattling sounds. Flexibility options, such as flexible couplings or adaptable fittings, help accommodate slight pipe movement or misalignment, reducing stress and noise transmission. It’s vital to verify that fittings are designed for your specific pipe type—PVC, copper, or PEX—to avoid issues down the line. Additionally, considering compatibility with automation technologies can streamline installation and future adjustments, ensuring a more efficient and reliable plumbing system. By choosing the right fittings and considering flexibility options, you create a more stable, quieter plumbing system that complies with codes and minimizes noise after changes.

Maintaining Correct Pipe Slope and Alignment

To guarantee proper drainage and prevent noisy pipes, you need to maintain the correct pipe slope and alignment during installation and repairs. Proper pipe slope ensures wastewater flows smoothly without pooling or air gaps that cause noise. Misaligned pipes can create vibrations and banging sounds during use. To ensure correct installation:

- Verify the pipe slope is at least 1/4 inch per foot for drain lines.

- Use level tools to check alignment continuously during setup.

- Secure pipes firmly to prevent shifting that disrupts slope and causes noise.

Maintaining the right pipe slope promotes efficient drainage, while proper alignment minimizes vibrations. Keep these points in mind to avoid future noisy pipe issues, ensuring your plumbing system operates quietly and effectively.

Checking for Adequate Water Pressure and Flow Rate

Start by measuring your water pressure to guarantee it’s within the recommended range. Then, assess the flow rate to see if it meets your household needs. Keep an eye out for sudden pressure fluctuations, which can cause noise and indicate underlying issues. For a cozy and functional space, consider how the bedroom layout affects water flow and pressure, especially in a farmhouse-style setting.

Measure Water Pressure Levels

How can you tell if your water pressure is adequate? First, check your pressure with a gauge on a faucet or hose bib. Aim for a reading between 40-60 psi. If it’s too high, it can cause noisy pipes and damage; too low, and your fixtures won’t perform well. To guarantee proper pressure:

- Attach a pressure gauge to a faucet and record the reading.

- Inspect for signs of inconsistent flow or sputtering.

- Consider installing pipe insulation to reduce noise dampening caused by pressure fluctuations.

- Regularly monitoring your water pressure can help maintain optimal water flow and system performance.

If your pressure is off, adjusting the pressure regulator or consulting a plumber is wise. Proper pressure helps prevent noisy pipes, especially after changes, and complements noise dampening measures like pipe insulation.

Assess Flow Rate Adequacy

Checking water pressure is just the first step; guaranteeing your flow rate is adequate confirms your fixtures perform properly. To do this, perform a flow measurement by opening a faucet fully and timing how long it takes to fill a container of known volume. This helps determine if your flow rate meets the needs of your household. If the flow is weak, it could indicate improper pipe sizing or restrictions in your plumbing system. Proper pipe sizing is vital to prevent noise and ensure consistent flow. You might need to upgrade or reconfigure pipes to improve flow rates. Regularly evaluating your flow rate helps catch issues early, prevents noisy pipes, and maintains your plumbing system’s efficiency. Additionally, understanding the importance of pipe sizing can help optimize your plumbing performance and reduce noise issues.

Identify Pressure Fluctuations

Are you noticing sudden changes in water pressure or irregular flow from your fixtures? These pressure fluctuations may cause noise and indicate issues with your plumbing system. To identify pressure surges and flow irregularities, check for:

- Sudden spikes or drops in water pressure when multiple fixtures are in use.

- Inconsistent flow rates, such as weak or interrupted streams.

- Noisy pipes that rattle or bang during pressure changes.

- Symptoms of water pressure problems, such as pipe noise or leaks, can help you determine if your pressure is too high, too low, or fluctuates unpredictably. Pressure surges can stress pipes, leading to leaks or noise. Regularly observe your system’s behavior, especially after recent changes, to guarantee your water pressure and flow are stable and compliant.

Implementing Proper Venting and Air Release Methods

Proper venting and air release methods are essential to prevent noisy pipes after changes. You need to ensure your plumbing system has adequate air venting to allow air to escape smoothly, reducing pressure buildup that causes noise. Installing properly positioned air vents or air release valves helps maintain balanced pressure and prevents air pockets from forming. When water flows, trapped air can create banging or gurgling sounds; releasing this air efficiently minimizes these issues. Regularly inspect vents and air release devices to confirm they’re functioning correctly. Proper venting not only quiets your pipes but also maintains system efficiency and longevity. Additionally, installing air admittance valves can help prevent negative pressure and reduce noise in the plumbing system. By implementing effective air release methods, you prevent the common causes of pipe noise and keep your plumbing system operating smoothly.

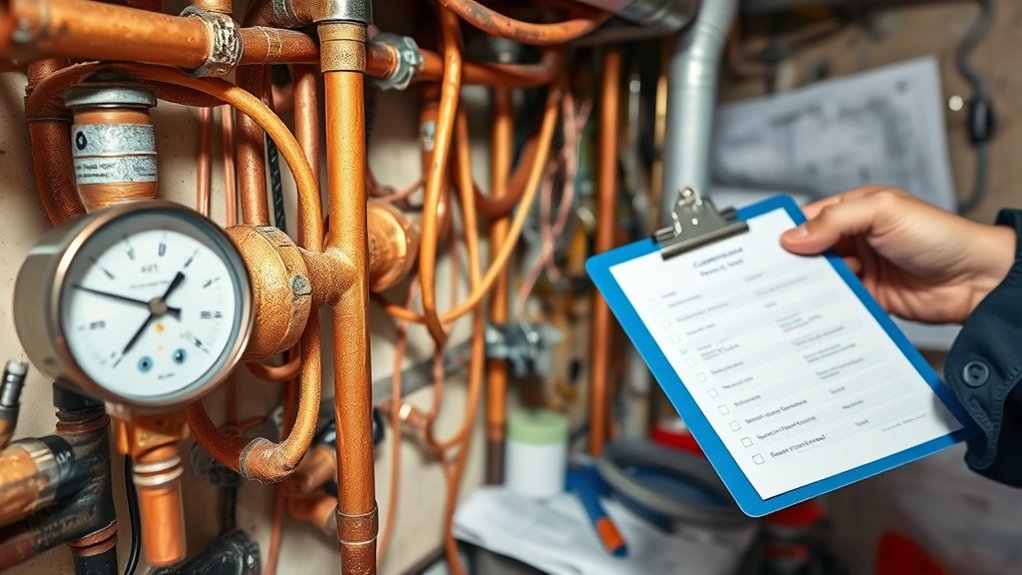

Conducting Post-Installation Inspection and Testing

Once the installation is complete, conducting a thorough post-installation inspection and testing guarantees your plumbing system functions correctly. Check for proper pipe insulation to prevent heat loss and reduce noise transmission. Listen for any remaining noises, ensuring pipes are securely fastened and free from vibrations. Verify that acoustic dampening measures are effective by running water through all fixtures and noting any persistent sounds.

Key steps include:

- Inspect all pipe connections for leaks or looseness.

- Test water flow and pressure to confirm proper operation.

- Evaluate noise levels, adjusting pipe supports or adding additional dampening if needed.

Consulting With Licensed Plumbing Professionals

Consulting with licensed plumbing professionals guarantees that your system meets safety standards and operates efficiently. They can identify the root causes of noisy pipes and recommend effective solutions, such as proper pipe insulation or noise dampening techniques. Professionals have the expertise to assess your current setup and ensure your pipes are correctly secured and insulated to minimize vibrations and sound. They can also advise on best practices for reducing noise after modifications, helping you avoid future issues. Engaging a licensed pro ensures compliance with local codes and prevents costly mistakes. Whether installing additional insulation or adjusting pipe hangers, their guidance ensures long-term quiet operation and system reliability. Don’t skip expert advice—it’s key to resolving noisy pipes safely and effectively.

Frequently Asked Questions

Can Noisy Pipes Indicate Hidden Leaks or Water Damage?

Yes, noisy pipes can indicate hidden leaks or water damage. When you hear banging or hissing sounds, it might mean water is escaping and causing unseen damage. These noises often point to pressure issues or leaks behind walls and under floors. Ignoring them can lead to serious water damage over time. It’s vital to examine further to prevent costly repairs and ensure your plumbing remains in good condition.

How Long Should New Plumbing Installations Take to Settle?

New plumbing installations typically take about 24 to 48 hours to fully settle. During this settling period, you might notice minor noises or slight movement as the pipes stabilize in their new positions. To guarantee everything is functioning correctly, check for leaks and proper water flow after this timeframe. Keep in mind that factors like pipe material and system complexity can influence the installation timeline and settling period.

Are There Specific Noise Reduction Devices Recommended for Residential Pipes?

Yes, you can reduce noise in your residential pipes by using vibration dampers and pipe insulation. Vibration dampers absorb and minimize pipe movement and noise caused by water flow, while pipe insulation helps dampen sound transmission through the walls and floors. Installing both in strategic locations, like near faucets, valves, or noisy sections, effectively quiets your plumbing system and improves overall comfort without extensive modifications.

What Are the Common Signs of Improper Pipe Support Causing Noise?

When your pipes start singing or rattling like a busy highway, improper pipe support is the culprit. Look for vibrations, banging sounds, or pipes that seem loose or sagging. These signs indicate inadequate support, making your plumbing prone to noise. To silence the chaos, focus on proper pipe support to stabilize and secure your pipes, a key step in effective noise mitigation. Fixing supports restores harmony and quietness to your plumbing symphony.

How Often Should Plumbing Systems Be Inspected for Noise Issues?

You should inspect your plumbing system at least once a year for noise issues. Regular inspection frequency helps catch problems early, preventing costly repairs. During inspections, look for loose pipes, unusual vibrations, or banging sounds. Follow maintenance tips like securing pipes properly and insulating them if needed. Staying proactive guarantees your plumbing remains quiet and efficient, reducing the risk of noise caused by improper supports or other issues.

Conclusion

By following these steps, you can markedly reduce noisy pipes after code updates, ensuring a quieter, more reliable plumbing system. Did you know that improper pipe installation can cause up to 70% of household water noise issues? Addressing the source of the noise and adhering to local regulations can save you time and money. Take proactive steps today—your peaceful, leak-free home depends on it.