A no-nonsense guide to softener regeneration explains how your water softener restores its efficiency by replacing mineral buildup on resin beads with a saltwater solution. Key terms include resin beads, which swap calcium and magnesium for sodium, and the control valve that manages cycles. The process involves flushing out minerals and renewing the beads, typically every few days. Understanding these steps helps you keep your softener running smoothly—more details reveal helpful tips to maintain peak performance.

Key Takeaways

- Softener regeneration restores resin beads’ mineral exchange capacity by flushing a brine solution that replaces calcium and magnesium with sodium ions.

- Key components include resin beads, control valve, brine tank, and ion exchange process, all crucial for effective regeneration.

- The typical cycle involves flushing with saltwater, exchanging ions, and rinsing out excess minerals and brine.

- Regeneration frequency (every 3-7 days) depends on water usage and system demands to maintain softening efficiency.

- Proper maintenance like backwashing, salt level checks, and removing salt bridges ensures optimal softener performance.

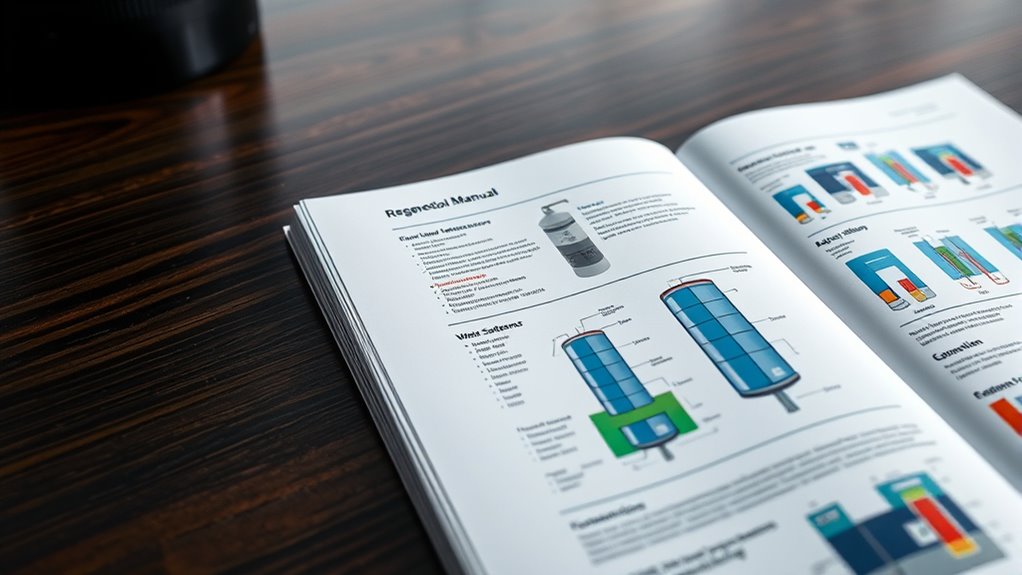

What Is Softener Regeneration?

Have you ever wondered what happens when a water softener needs to keep working effectively? That’s where softener regeneration comes in. It’s the process that restores your unit’s water softener efficiency by removing the mineral buildup on resin beads. Over time, these beads become saturated with calcium and magnesium, reducing their ability to soften water. During regeneration, a brine solution is flushed through the resin tank, washing away the accumulated minerals. This process not only keeps your water softener functioning properly but also helps extend the resin bead lifespan. Without regular regeneration, your system’s performance drops, leading to harder water and increased wear on the components. Proper voiceover techniques used in educational materials can enhance understanding of these processes. So, regeneration is essential for maintaining ideal operation and ensuring your water stays soft and clean.

Key Terms and Components in Regeneration

Understanding the key terms and components involved in regeneration helps you better grasp how your water softener works. The process mainly involves ion exchange, where resin beads capture hardness minerals like calcium and magnesium. Here are the essential components:

- Resin Beads: Tiny, plastic beads coated with sodium ions that attract and swap ions with hard minerals during ion exchange.

- Control Valve: Manages the flow of water and initiates regeneration cycles.

- Brine Tank: Contains saltwater that regenerates the resin beads by replenishing sodium ions, preparing them for the next softening cycle.

- Contrast Ratio is also an important factor that influences the perceived sharpness and clarity of images, which is crucial when selecting a projector for home entertainment.

The Regeneration Process Step-by-Step

Once the key components are in place, the regeneration process begins to restore the resin beads’ ability to soften water. You’ll start by flushing the system with a brine solution, which contains high salt concentration. This step allows sodium ions to replace the calcium and magnesium ions trapped on the resin. Proper regeneration timing is essential here; doing it too early wastes salt and water, while waiting too long decreases softener efficiency. As the brine moves through the resin bed, the exchange process renews the beads’ capacity to remove hardness minerals. Afterward, excess brine and displaced minerals are flushed out with fresh water. Monitoring system performance and regeneration cycles helps ensure your softener operates effectively, maintaining water softness and optimizing its lifespan.

Common Regeneration Cycles and Why They Matter

Regularly scheduled regeneration cycles are crucial for maintaining your water softener’s efficiency and prolonging its lifespan. Understanding common regeneration cycles helps you maximize performance. Typically, these cycles occur based on your water usage and the regeneration cycle frequency you choose. Here are key points to contemplate:

- Standard cycles usually happen every 3-7 days, depending on household water demand.

- Some systems offer alternative regeneration methods, like meter-based or demand-initiated cycles, reducing unnecessary regenerations.

- Adjusting the regeneration cycle frequency guarantees your softener works efficiently without waste, saving you money and extending its life.

- Incorporating Honda Tuning principles, such as precise adjustments and system optimization, can help ensure your water softener operates at peak efficiency.

Choosing the right cycle type and frequency is essential for ideal softening and system longevity.

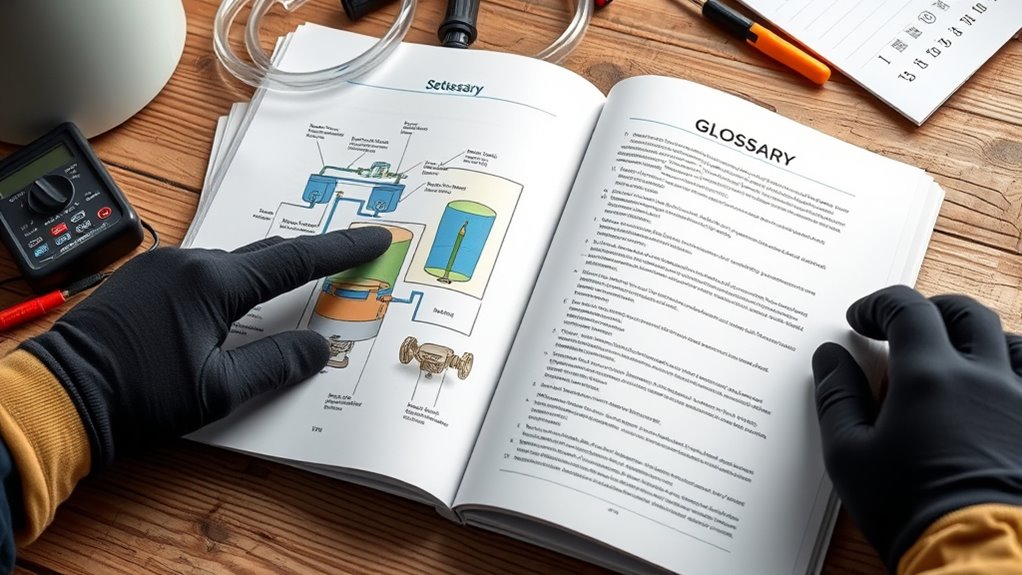

Troubleshooting and Maintenance Vocabulary

To keep your water softener running smoothly, it’s essential to understand key troubleshooting and maintenance terms. The backwash procedure is a vital step that flushes out trapped debris and regenerates resin beads, ensuring top-notch performance. Regular brine tank maintenance prevents salt bridges and buildup that can impair regeneration. This includes checking salt levels, cleaning out sediment, and ensuring the salt dissolves properly. Familiarity with these terms helps you identify issues early, such as poor water softening or slow regeneration. Knowing how to perform a backwash or maintain the brine tank allows you to troubleshoot common problems effectively, saving time and costly repairs. Proper understanding of juice extraction techniques can also help in maintaining clean components and ensuring optimal performance of your softener. Keeping these concepts in mind ensures your softener functions efficiently and extends its lifespan.

Frequently Asked Questions

How Often Should a Water Softener Be Regenerated?

You should regenerate your water softener when the resin’s capacity diminishes, typically every 7 to 14 days, depending on your water usage. Regular backwash frequency helps maintain resin efficiency and extends its lifespan. Keep an eye on your water hardness levels; if they increase, it’s time for regeneration. Consistent scheduling guarantees your softener functions properly, preventing mineral buildup and maximizing resin lifespan.

Can I Skip Regeneration Cycles Without Damaging the System?

Skipping regeneration cycles is like trying to run a vintage computer without updates—you risk system damage. You shouldn’t skip regeneration frequency because it’s essential for maintaining softener efficiency. If you ignore the cycle, minerals build up, clogging the system and reducing its lifespan. Stick to the recommended schedule to keep your water softener working properly and avoid costly repairs or system damage down the line.

What Are Signs That Regeneration Is Not Working Properly?

You’ll notice increased water hardness, with soap not lathering well or soap scum forming. If your water feels gritty or you see mineral deposits, the regeneration isn’t effective. Reduced salt efficiency means the system isn’t removing minerals properly, leading to less softened water. Additionally, frequent regeneration cycles or a sudden spike in water hardness are signs that your softener isn’t functioning correctly and needs maintenance or adjustment.

Does Regeneration Use a Lot of Water and Salt?

Regeneration does use some water and salt, but it’s usually efficient. You’ll notice increased water consumption during the regeneration cycle, which is necessary to rinse out the old minerals. Salt usage varies based on the system size and settings, but generally, it’s a manageable amount. Proper maintenance guarantees you’re not wasting too much salt or water, keeping your softener running smoothly and cost-effectively.

Are There Environmentally Friendly Alternatives to Traditional Regeneration?

Yes, there are eco-friendly options and alternative solutions to traditional regeneration. You can consider using salt-free water softeners that rely on alternative technologies like template-assisted crystallization or magnetic systems. These options typically use less water and avoid salt, making them more environmentally friendly. By choosing eco-friendly options, you reduce your carbon footprint and help protect water resources while still enjoying softened water.

Conclusion

Think of softener regeneration as tending a garden—you nurture it regularly, and it blooms beautifully. By understanding the key terms, steps, and maintenance, you keep your system running smoothly. When you grasp these concepts, you’re like a skilled gardener, ensuring your water softener stays healthy and efficient. With this knowledge, you’ll prevent hiccups and enjoy the steady flow of soft water, making your home’s water system flourish like a well-tended garden in full bloom.