To prevent channeling in media tanks, focus on proper design and flow management. Avoid overfilling the tank, as this increases resistance and creates flow paths. Use internal baffles or flow distributors to guide media evenly, and position inlets and outlets carefully to prevent high-velocity jets from carving channels. Regular maintenance and testing help identify issues early. Continuing with these practices will reveal more effective strategies to keep flow uniform and extend your media’s lifespan.

Key Takeaways

- Design tanks with rounded shapes and internal baffles to promote uniform flow and prevent channel formation.

- Position inlets and outlets strategically to avoid high-velocity jets that cause flow concentration.

- Ensure media is not overcrowded to reduce resistance and encourage even distribution.

- Regularly maintain and clean tanks to prevent build-up and clogging that obstruct flow paths.

- Use flow distributors and testing tools to verify flow patterns and make necessary adjustments.

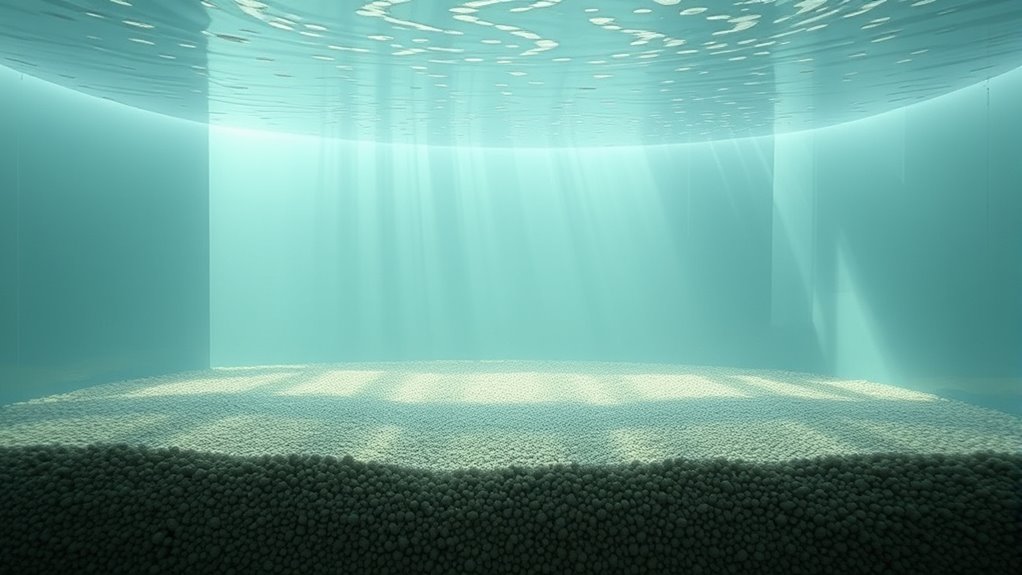

Channeling in media tanks occurs when flow paths become concentrated, causing uneven distribution of fluids and reducing system efficiency. When this happens, your media flow doesn’t spread evenly across the tank, leading to dead zones and decreased performance. To prevent this, you need to understand how tank design influences flow patterns. Proper tank design ensures media flow remains uniform, minimizing the risk of channeling. Factors such as tank shape, internal baffles, and inlet/outlet placement play vital roles in guiding flow smoothly throughout the system. For example, tanks with rounded or tapered shapes promote more even flow, whereas sharp corners can create stagnation points. Incorporating internal baffles or flow distributors is essential; these components help break up flow paths, preventing concentrated streams from forming and encouraging media to move uniformly. When designing or modifying a tank, always consider how the media will circulate within the space. Proper placement of inlets and outlets ensures that incoming fluids don’t create high-velocity jets that carve out channels. Instead, the flow should distribute gently across the media, promoting thorough contact and effective treatment. If your tank has poor inlet positioning, you risk creating areas of high flow velocity that cause media flow to concentrate along specific paths. This not only reduces efficiency but also accelerates media degradation or clogging in those zones. Regularly inspecting your media tank helps identify early signs of channeling, such as uneven media distribution or localized clogging. If you notice uneven flow, it might be time to revisit your tank design or adjust operational parameters. Sometimes, small modifications—like adding flow diffusers or repositioning inlet/outlet ports—can substantially improve media flow. Avoid common mistakes such as overcrowding the tank with media, which increases resistance and encourages channeling, or neglecting maintenance, which allows build-up and flow obstruction. Also, resist the temptation to use a one-size-fits-all tank design; each system has unique flow requirements, and customizing tank features can enhance media flow and system longevity. Additionally, utilizing testing tools can help verify flow patterns and identify problematic areas early. Remember, the goal is to promote a consistent, gentle flow that allows media to contact the fluid uniformly. This not only prevents channeling but also boosts system efficiency and extends media lifespan. In short, thoughtful tank design combined with proper flow management is key to preventing channeling. By paying attention to how media moves within your tank and making strategic adjustments, you guarantee your system operates at peak performance while avoiding costly downtime or repairs caused by uneven flow patterns.

Frequently Asked Questions

How Does Media Type Influence Channeling Prevention?

Your choice of media type directly impacts channeling prevention by ensuring media compatibility with your tank and process. Select media that promotes even flow distribution, reducing the risk of uneven settling or blockages. For example, granular media like sand or gravel facilitate better flow, while fine powders may require specific handling to prevent channeling. By matching media type to your system, you optimize flow and minimize channeling risks effectively.

What Are Early Signs of Channeling in Tanks?

Early signs of channeling are like cracks forming on a surface—you’ll notice visual indicators such as uneven flow or dead zones inside the tank. Flow irregularities might include inconsistent agitation, sediment buildup, or sudden changes in pressure. These clues suggest the media isn’t moving evenly, which could lead to channeling. Spotting these signs early helps you address issues before they worsen, ensuring ideal tank performance and media distribution.

Can Temperature Fluctuations Cause Channeling Issues?

Yes, temperature fluctuations can cause channeling issues in media tanks. When you lack proper tank insulation, temperature swings create uneven media flow, leading to channel formation. To prevent this, verify temperature stabilization by maintaining consistent temperatures, which helps media settle evenly. Proper insulation reduces temperature variations, promoting uniform media distribution and minimizing the risk of channeling. Regular monitoring and adjustments keep your tank operating smoothly and efficiently.

How Often Should Media Tanks Be Inspected for Channeling?

You should inspect your media tanks regularly, ideally every 3 to 6 months, as part of your tank maintenance and inspection schedules. Frequent checks help you identify early signs of channeling, such as uneven media distribution or flow issues. By maintaining a consistent inspection routine, you reduce the risk of channeling problems, ensuring best filtration performance and prolonging the lifespan of your media tanks.

Are There Specific Tools to Detect Channeling in Media Tanks?

Imagine peering into your media tank like a detective searching for clues. You can use visual inspection to spot obvious signs of channeling, like uneven media levels or gaps. For more precision, ultrasonic testing acts like a high-tech sonar, revealing hidden voids and inconsistencies inside the tank walls. Together, these tools help you detect channeling early, ensuring your media stays evenly distributed and your process runs smoothly.

Conclusion

To prevent channeling in media tanks, stay vigilant, stay consistent, and stay informed. Monitor your tank regularly, adjust your media evenly, and address issues promptly. Keep your media distributed, your flow uniform, and your tank balanced. By doing so, you guarantee even filtration, peak performance, and a healthier system. Remember, prevention starts with awareness, action, and maintenance—because a well-maintained tank is a well-functioning tank. Stay proactive, stay effective, and keep your media tank running smoothly.