To prevent channeling in media tanks quickly, focus on maintaining proper media density and even loading practices, such as gradual addition and pre-wetting. Use internal baffles or inserts to direct flow and create turbulence, reducing preferred pathways. Regularly inspect and clean the media, adjust flow rates, and consider adding media treatments that promote stability. Implementing these strategies will help you guarantee consistent filtration performance and avoid costly system issues—stay tuned for more helpful tips.

Key Takeaways

- Ensure proper media density and even loading, pre-wetting media to prevent gaps and reduce channel formation.

- Incorporate internal baffles and agitators to direct flow and maintain uniform media distribution.

- Regularly inspect and clean media, replacing worn or loose media promptly to sustain filtration efficiency.

- Use flow monitoring tools and visual inspections to detect early signs of channeling for quick corrective action.

- Apply chemical additives or media treatments designed to enhance media stability and minimize preferential flow paths.

What Causes Channeling in Media Tanks and How Can You Spot It?

Channeling in media tanks occurs when the media forms narrow, preferential flow paths rather than distributing evenly throughout the tank. This uneven media flow is often caused by media segregation, where different particle sizes separate over time, creating gaps and channels. You’ll notice this when media clusters in certain areas, leaving others empty, which can reduce contact between the media and the fluid. Signs of channeling include uneven pressure drops, inconsistent flow rates, and poor filtration performance. To spot it, look for areas where media is less dense or missing altogether, especially near the outlet or inlet. Recognizing these signs early helps prevent further issues and guarantees your media tank functions effectively, maintaining ideal flow and filtration efficiency. Additionally, regular inspection and proper media mixing can help minimize media segregation and improve overall system performance.

How Does Media Density Affect Channeling, and What Are the Best Practices?

Media density plays a critical role in preventing channeling because denser media promotes uniform flow and minimizes the formation of preferential pathways. When media is dense, it resists movement irregularities, helping maintain a steady flow rate throughout the tank. If the media is too light or loose, it can create gaps where flow accelerates, leading to channeling. To optimize media density, avoid overloading the tank and ensure consistent packing. Regularly monitor the flow rate to detect signs of uneven distribution, such as sudden drops or surges. Proper media compaction and avoiding gaps help maintain desired density levels. Ultimately, controlling media density ensures a more stable flow, reduces the risk of channeling, and improves the efficiency of media tank operations.

Which Tank Design Features Help Minimize Channeling Risks?

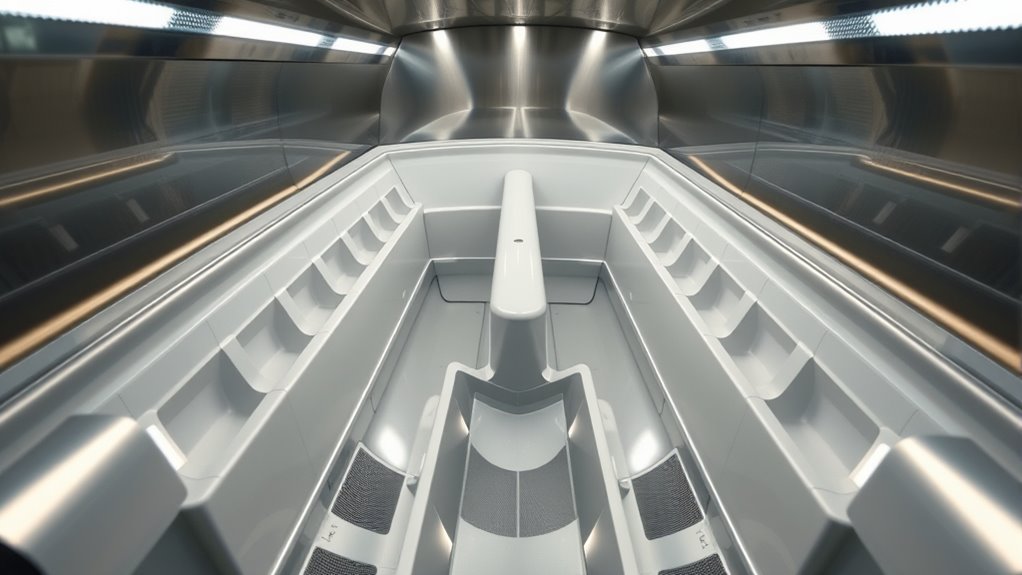

Design features of a tank play an essential role in reducing the risk of channeling by promoting even flow distribution. Proper media agitation keeps the media uniformly mixed, preventing stagnant zones that can cause uneven flow paths. Tank baffling is equally important; installing internal baffles directs media movement and discourages the formation of preferred flow channels. Baffles help distribute media more evenly across the tank, minimizing dead zones and ensuring consistent contact with the media. Additionally, designing the tank with appropriate inlet and outlet placements promotes smooth media circulation. Combining effective media agitation with strategic baffling creates a balanced environment that reduces channeling risks. These features help maintain ideal flow, improve treatment efficiency, and extend the lifespan of your media tank.

What Role Do Internal Baffles and Inserts Play in Ensuring Even Media Distribution?

Internal baffles and inserts play a essential role in promoting uniform media distribution within a tank. Proper baffle design helps direct media flow, preventing channels from forming and guaranteeing even media placement throughout the tank. By disrupting direct flow paths, baffles eliminate dead zones and reduce the risk of channeling, which can compromise process efficiency. Inserts further optimize media distribution by creating additional contact points and promoting turbulence. When you choose the right baffle design, you improve media contact with the tank walls and media bed, leading to better mixing and contact time. This setup ensures your media is evenly distributed, which is indispensable for maximizing process performance and preventing channeling issues. Properly installed internal baffles and inserts are key to achieving consistent, reliable media contact. Additionally, incorporating rustic decor elements can enhance the aesthetic appeal of the tank setup in a farmhouse-inspired environment, blending functionality with rustic charm.

How Can Proper Media Loading Techniques Prevent Channeling?

By using proper media loading techniques, you can achieve more uniform media distribution throughout the tank. Proper layering methods help prevent gaps and channels that cause uneven flow. When you load media correctly, you reduce the risk of channeling and guarantee ideal system performance. Additionally, selecting the appropriate self-watering plant pots can contribute to maintaining consistent moisture levels, further minimizing flow issues.

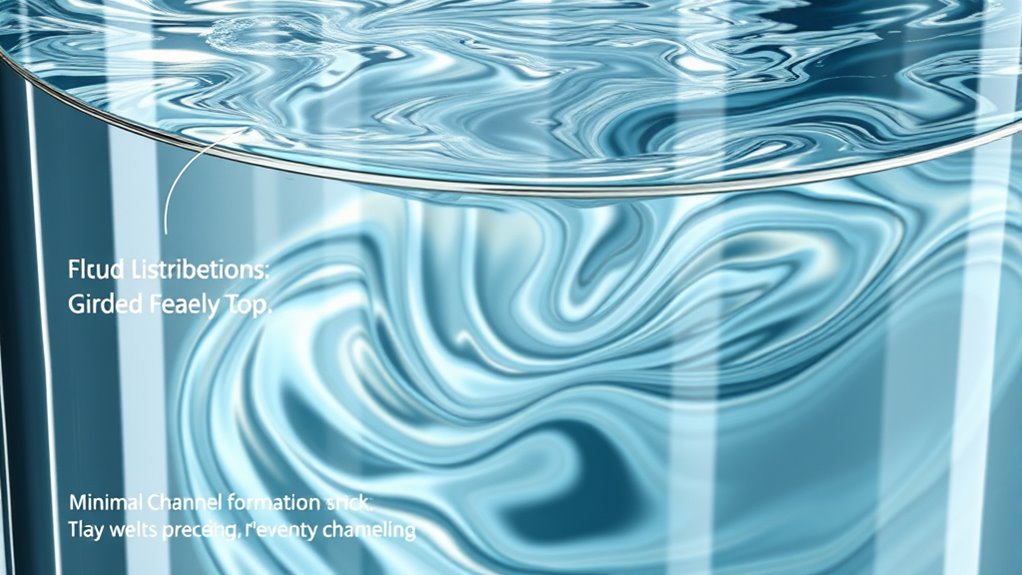

Uniform Media Distribution

When media is loaded unevenly, it creates pathways that allow fluid to bypass the media bed, leading to channeling. To prevent this, guarantee a uniform media distribution across the tank. Proper loading promotes even media flow, reducing the risk of channels forming. Additionally, maintaining consistent tank agitation helps keep the media bed evenly mixed, preventing media from settling unevenly. By distributing media properly, you create a stable environment where fluid is forced to pass through the entire media bed rather than finding shortcuts. This not only improves filtration efficiency but also prolongs media life. Incorporating media tuning techniques can further optimize the distribution process. Consistent media loading combined with effective tank agitation is key to avoiding the formation of channels, ensuring your media tank operates smoothly and efficiently.

Proper Layering Methods

Proper layering techniques are essential for preventing channeling because they guarantee media is evenly distributed throughout the tank. When you focus on correct media layering, you improve flow distribution and reduce dead zones. Start by adding media gradually, ensuring each layer is uniform. Use a back-and-forth motion to spread media evenly, avoiding gaps. Consider pre-wetting media to minimize dust and improve packing. Regularly check the media height to maintain proper flow. Avoid overloading, which can cause uneven flow paths. Proper layering ensures consistent contact between media and influent, reducing the risk of channeling. Incorporating industry trends and best practices helps optimize the process and prevent issues.

What Maintenance Strategies Keep Media Tanks Operating Smoothly?

Regular maintenance is essential to keep media tanks operating smoothly and prevent channeling issues. You should regularly inspect the media for signs of wear and replace it when necessary to guarantee ideal flow and filtration. Media replacement helps maintain proper media bed depth and prevents clogging, which can lead to uneven flow paths. In addition, consistent tank cleaning is vital; it removes debris, sludge, and buildup that can cause blockages or uneven media distribution. Schedule routine cleaning to avoid buildup that hampers performance. Proper maintenance also includes checking for damaged or broken media and replacing it promptly. Additionally, understanding symptoms such as clogged filters can help identify early signs of system inefficiency. By staying on top of media replacement and tank cleaning, you minimize the risk of channeling and keep your media tank functioning efficiently, ultimately extending its lifespan.

Are There Effective Additives or Treatments That Reduce Channeling?

Chemical additives can help minimize channeling when used correctly, but their effectiveness depends on proper application. You need to follow recommended treatment techniques to guarantee even distribution and ideal results. You can improve your approach by understanding the importance of consistent practice, which ensures that treatments are effectively integrated into the system. Are you confident your current approach is maximizing these treatments’ benefits?

Chemical Additives Effectiveness

While chemical additives are often considered for reducing channeling in media tanks, their effectiveness varies depending on the situation. Successful results hinge on proper chemical compatibility and careful additive selection. Some additives can improve flow and prevent dead zones, but not all work equally well in every system. It’s essential to test compatibility before use to avoid adverse reactions. When choosing additives, consider factors like pH stability, solubility, and the specific media being treated. Keep in mind that improper additive selection can worsen channeling or cause equipment issues. Here are some key points to remember:

- Compatibility with existing chemicals

- Proper dosage for effectiveness

- Compatibility with tank materials

- Avoiding over-treatment or under-treatment

- Monitoring results to adjust as needed

Proper Treatment Techniques

Effective treatment techniques are essential for minimizing channeling in media tanks, especially when selecting appropriate additives or methods. To reduce issues, you should consider using specialized media treatment options designed to improve flow and prevent clumping. Properly mixing and distributing media within the tank ensures uniform contact and minimizes voids that cause channeling. Mechanical methods, such as agitation or aeration, can also help keep media evenly distributed. Additionally, some additives or coatings can enhance media stability and reduce settling or segregation. Regular inspection and maintenance of your media tank allow you to identify early signs of channeling and apply corrective treatments promptly. Moreover, understanding the importance of contrast ratio can help in optimizing visual monitoring of your tanks during operation, ensuring better detection of flow irregularities. By combining effective media selection with proper handling techniques, you can considerably reduce channeling and improve overall tank efficiency.

How Can Regular Monitoring and Inspection Improve Tank Performance?

Regular monitoring and inspection are essential for identifying potential issues before they escalate, guaranteeing your media tanks operate efficiently. Consistently checking sensor calibration helps maintain accurate readings, preventing channeling caused by faulty data. Regular inspections allow you to spot signs of media degradation or clogging early, facilitating timely media replacement. This proactive approach minimizes downtime and optimizes tank performance. Additionally, inspecting flow patterns can reveal uneven distribution, helping you address problems before they worsen. Incorporating essential oil benefits can also promote a healthier system environment by reducing microbial growth and contamination. By maintaining a routine, you ensure your system stays in top shape, reducing the risk of costly repairs. Remember, vigilant monitoring isn’t just about reactive fixes—it’s about preventing issues altogether, keeping your media tanks functioning smoothly and efficiently.

Frequently Asked Questions

How Does Media Type Influence the Likelihood of Channeling in Tanks?

You’ll find that media type greatly influences the likelihood of channeling due to media viscosity and composition. Thicker, more viscous media tends to resist flow, reducing channeling risks, while lighter media flow more easily, increasing it. The media’s composition, such as particle size and fluid properties, also affects how evenly it distributes in the tank. Selecting the right media type helps prevent channeling and ensures better media contact and efficiency.

What Are Cost-Effective Methods to Retrofit Existing Tanks for Better Media Flow?

Think of your tank as a well-orchestrated dance, and retrofit techniques as the choreography that keeps everyone moving smoothly. To retrofit cost-effectively, perform a thorough cost analysis to identify priority areas. Use simple methods like installing baffles or modifying inlet/outlet designs, which improve media flow without breaking the bank. These adjustments guarantee better media distribution, preventing channeling and enhancing overall tank efficiency on a budget.

Can Temperature Variations Impact Channel Formation in Media Tanks?

Yes, temperature variations can impact channel formation in media tanks. When temperatures fluctuate, thermal expansion causes material movement, which can create or enlarge channels. Additionally, pressure fluctuations from temperature changes can alter media flow, encouraging channeling. To prevent this, you should control tank temperatures and monitor pressure changes closely, ensuring consistent conditions that minimize thermal expansion effects and maintain even media distribution.

How Do Operational Cycle Times Affect Media Channeling Risks?

Imagine you’re running a media tank, and longer cycle times lead to uneven flow. Longer operational cycle times can increase channeling risks by allowing settled media to form uneven pathways, reducing operational efficiency. To mitigate this, you should optimize cycle durations and regularly monitor flow patterns. This proactive risk mitigation guarantees consistent media distribution, enhances operational efficiency, and prevents channeling issues that can compromise tank performance and safety.

What Training Protocols Help Staff Identify Early Signs of Channeling?

You should implement training protocols that focus on recognizing visual cues, such as uneven media flow or stagnant areas, which signal potential channeling. Regular staff drills are essential to reinforce these skills and guarantee quick, effective responses when early signs appear. By practicing these protocols, your team becomes more adept at identifying and addressing channeling issues before they escalate, maintaining ideal media tank performance and safety.

Conclusion

By understanding what causes channeling and implementing these quick wins, you can prevent costly issues and keep your media tanks running smoothly. Don’t think you need fancy equipment or complex solutions—simple design tweaks, proper maintenance, and regular checks make a big difference. Even if you’re short on time or resources, these easy strategies will help you maintain even media distribution and optimize tank performance without hassle.