To quickly fix leaks at unions and understand threaded connections, start by inspecting your fittings for moisture, corrosion, or puddles. Tighten loose nuts carefully, using the right tools like a wrench or thread file. Applying Teflon tape or sealant can seal small drips, but avoid overtightening. Recognize common thread types and their compatibility to prevent future leaks. Mastering these simple steps now can save you time—continue exploring for even more effective solutions.

Key Takeaways

- Tighten loose unions gradually with a wrench, avoiding over-tightening that can damage threads or gaskets.

- Apply Teflon tape or thread sealant properly to threaded connections before reassembling to prevent leaks.

- Inspect unions and threads for corrosion, moisture, or damage, and replace worn gaskets or defective parts promptly.

- Use a threads glossary to identify thread types (e.g., NPT, BSP) and ensure compatibility for secure, leak-free connections.

- Schedule quick routine inspections to catch early signs of leaks, like moisture or corrosion, and address issues immediately.

Understanding Union Leaks and Why They Matter

Have you ever wondered what happens when confidential union information gets leaked? It’s a serious issue that can damage relationships and compromise union activities. Understanding union leaks is essential for effective union maintenance, which involves regular inspections and prompt repairs to prevent issues. Leak prevention starts with identifying weak points in union joints and threads, where leaks often originate. By ensuring proper installation and using quality sealing materials, you can considerably reduce the risk of leaks. Recognizing the importance of these measures helps protect sensitive information and maintains the integrity of union systems. Regular filter replacement and monitoring air quality indicators are also crucial practices to prevent leaks and ensure system efficiency. Staying vigilant and proactive in leak prevention not only safeguards your union’s operations but also fosters trust and transparency among members.

Common Causes of Leakage at Pipe Unions

Leaks at pipe unions often originate from improper installation or manufacturing defects. Poor union maintenance can cause components to loosen or misalign, leading to gaps where leaks develop. Over-tightening or uneven tightening during assembly stresses the seals and threads, increasing leak risk. Manufacturing flaws, such as damaged or worn gaskets, weaken the seal and allow fluid escape. Inadequate leak detection during routine inspections can cause minor issues to go unnoticed, worsening over time. Regular union maintenance helps identify loose fittings or worn parts early, preventing leaks from worsening. Ensuring proper installation techniques, inspecting seals, and maintaining tight, even connections are essential steps. Understanding store hours and service availability can assist in scheduling timely maintenance visits. Addressing these common causes promptly keeps your piping system leak-free and extends its lifespan.

Recognizing Signs of a Leak in a Union

Detecting a leak early can save you time and prevent costly repairs. During union maintenance, look for signs like moisture, corrosion, or rust around the connection. Puddles or damp spots beneath the union indicate potential leaks. Listen for hissing sounds or irregular noises that suggest escaping air or fluid. Visible corrosion or discoloration can also signal a leak in progress. Keep an eye out for increased pressure drops or fluctuations in your system’s performance, which are common leak detection clues. Regular inspections help catch leaks before they worsen. Being vigilant and recognizing these signs ensures you can address leaks promptly, maintaining system integrity and avoiding extensive damage down the line. Quick identification is essential for effective leak detection and union maintenance. Understanding how halloween decorations can impact your system’s visibility might also help in early leak detection.

Basic Types of Threaded Connections

Understanding the basic types of threaded connections is essential for effective union maintenance. You’ll encounter various types based on thread diameter and thread length, which influence how securely components fit together. Common types include external threads, like bolts, and internal threads, such as nuts or fittings. These connections can be tapered or straight, affecting how they seal and withstand pressure. Thread diameter determines the size of the connection, while thread length impacts the connection’s strength and leak prevention. Properly matching thread diameter and length guarantees a tight, leak-proof seal. Recognizing these differences helps you select the right threaded connection for each application, reducing leaks and maintenance issues. Additionally, understanding thread engagement and proper torque application is crucial for ensuring durable, leak-free unions. Accurate understanding of these basic types is fundamental to maintaining reliable, leak-free unions.

What Are TPI and Pitch in Threads?

Have you ever wondered how to quickly identify a thread’s size? TPI, or threads per inch, helps you do that by showing how many threads fit in one inch. Understanding pitch measurements and seeing practical thread examples make it easier to choose and work with the right threaded connections. Recognizing personality traits can also enhance communication and teamwork in various settings.

TPI Explained Clearly

Ever wondered what TPI and pitch mean when talking about threads? TPI, or Threads Per Inch, tells you how many threads fit into one inch. Pitch, on the other hand, measures the distance between threads. Both are key for guaranteeing thread compatibility between parts. Here’s what you need to know:

- TPI affects how well threads fit together and resist thread corrosion.

- Matching TPI is vital for proper assembly and avoiding leaks.

- Pitch and TPI are inversely related; a higher TPI means a smaller pitch.

- Correct TPI ensures threads are compatible, reducing risk of leaks and thread corrosion.

Understanding TPI helps you select the right threads, preventing damage and ensuring durability in your projects.

Pitch Measurement Basics

When working with threaded parts, knowing the difference between TPI and pitch is essential for guaranteeing proper fit and function. In piping design, pitch refers to the distance between threads, measured in millimeters or inches, while TPI (threads per inch) counts how many threads fit into one inch. Both measurements help you select the right thread type for leak prevention, reducing the risk of leaks at unions and joints. Accurate pitch measurement ensures threads mesh correctly, creating a tight seal. TPI is commonly used in the U.S., while pitch is standard internationally. Understanding these basics allows you to identify compatible threads quickly, preventing leaks and ensuring the integrity of your piping system. Proper thread matching is crucial for effective sealing and leak prevention. Mastering pitch measurement is a key step toward efficient, leak-free installations.

Practical Thread Examples

Understanding TPI and pitch becomes clearer when looking at practical thread examples. When selecting union materials, knowing TPI (threads per inch) and pitch helps guarantee ideal thread durability and proper fit. For example:

- Standard Pipe Threads: Usually have 11.5 TPI, balancing strength and ease of assembly.

- Fine Threads: Higher TPI, like 16 or 20, offering better thread engagement for high-pressure applications.

- Coarse Threads: Lower TPI, around 8 or 12, suitable for quick assembly and softer materials.

- Specialized Threads: Used in specific industries with unique pitch requirements for enhanced durability.

Additionally, understanding the contrast ratio of projectors can help you select models that deliver deeper blacks and brighter whites for a better viewing experience.

Different Thread Standards and Their Uses

Understanding different thread standards helps you choose the right type for your project. You’ll need to take into account common thread types, whether metric or imperial, and their specific application areas. Picking the correct standard ensures compatibility and reliable performance. Additionally, being aware of standard measurements can prevent mismatched parts and save time during assembly.

Common Thread Types

Have you ever wondered why different tools and machines use specific thread types? It’s mainly because each thread standard suits particular applications. Knowing these types helps prevent leaks and ensures proper sealing. Here are common thread types:

- NPT (National Pipe Thread) – designed for pipe material, providing a tight seal with thread lubrication.

- BSP (British Standard Pipe) – used internationally, especially in plumbing, with similar sealing properties.

- UNC/UNF (Unified National Coarse/Fine) – standard for bolts and screws, not typically for pipes.

- Metric threads – widely used globally, with precise dimensions for various piping needs.

Selecting the correct thread type also depends on the thread standards and compatibility with your equipment to avoid leaks or damage. Proper thread lubrication also plays a key role in preventing leaks.

Metric vs. Imperial Standards

When choosing thread standards, it’s important to recognize that metric and imperial systems serve different regions and applications. Metric standards, measured in millimeters, are common worldwide and favored for precise union design and consistent thread materials. They offer standardized sizes, making repairs and replacements straightforward across international markets. Imperial standards, primarily used in the U.S., involve inches and fractions, often tailored for specific industries or legacy equipment. Understanding these differences ensures you select the right thread type for your application, preventing leaks and fitting issues. Using the correct standard also optimizes union design, ensuring compatibility with thread materials and reducing the risk of thread damage or failure. Thread compatibility is crucial for ensuring a leak-free connection and long-term durability. Choosing the appropriate standard ultimately enhances reliability and ease of maintenance.

Application Areas and Compatibility

Different thread standards are suited for specific application areas, making compatibility essential for leak-free connections and reliable performance. Choosing the right thread type ensures union safety and prevents leaks in various systems. Knowing which standards fit your needs helps avoid mismatched threads and potential failures. Consider these key points:

- Pipe thread standards like NPT or BSP are common in plumbing and fluid systems.

- Material compatibility is crucial; threads made from brass, stainless steel, or plastic suit different environments.

- Application-specific threads ensure union safety in high-pressure or corrosive settings.

- Thread materials impact durability, sealing ability, and resistance to leaks, making the right choice indispensable for long-term performance.

Matching thread standards and materials guarantees leak-free, safe, and effective connections across industries.

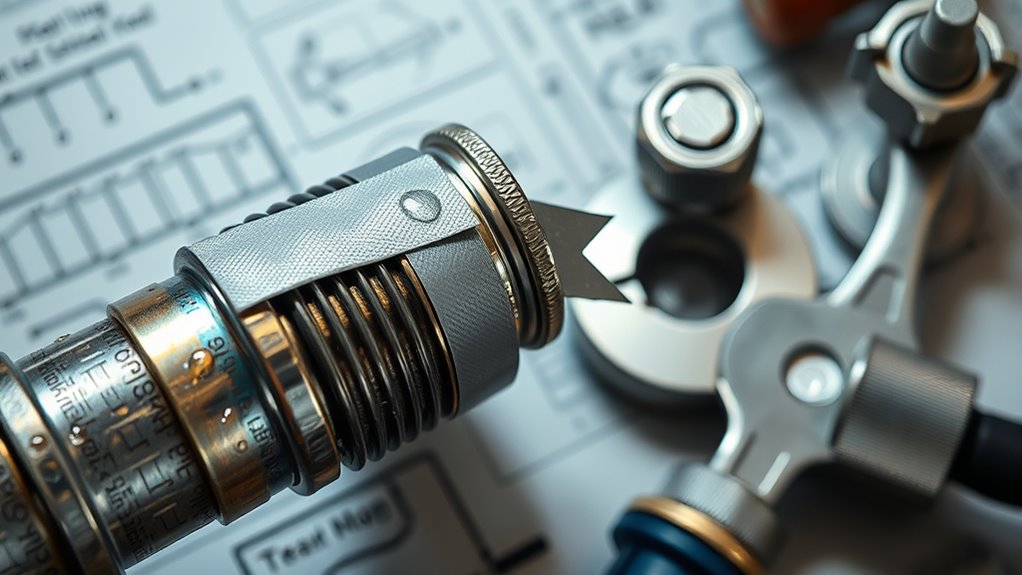

Tools Needed for Tightening and Sealing Threads

To effectively tighten and seal threads, you’ll need a few key tools that guarantee a secure fit and prevent leaks. A pipe wrench is essential for gripping and turning fittings during pipe fitting tasks. You’ll also need thread sealing tape, often called Teflon tape, to wrap around the threads, guaranteeing a tight seal. For more stubborn fittings, a thread sealant or pipe thread compound can provide extra security against leaks. A thread file or rethreading tool helps clean or repair damaged threads, ensuring proper sealing. Additionally, a torque wrench allows you to tighten fittings to the correct specifications without over-tightening. These tools work together to ensure proper thread sealing and reliable pipe fitting connections, markedly reducing the risk of leaks.

Simple Steps to Prevent Thread and Union Leaks

To prevent thread and union leaks, you should secure your accounts and manage permissions carefully. Limiting access reduces the risk of accidental or malicious leaks. Always review and update permissions regularly to maintain control and security.

Secure Your Accounts

Securing your accounts is the first step in preventing leaks at unions and threads. Strong, unique passwords protect your union safety and prevent unauthorized access. Enable two-factor authentication to add an extra layer of security. Regularly update your login details and monitor account activity for suspicious behavior. Additionally, keep thread lubrication and union safety in mind by avoiding sharing sensitive info or clicking unknown links. These simple steps help minimize the risk of leaks and guarantee your systems stay secure.

Here are four key actions:

- Use complex, unique passwords for each account

- Activate two-factor authentication wherever possible

- Regularly review account activity logs

- Avoid sharing sensitive information or clicking suspicious links

Manage Permissions Effectively

Managing permissions carefully is the next step in preventing leaks at unions and threads. Proper union maintenance ensures only authorized users access sensitive information, reducing the risk of accidental leaks. Regularly review and update permissions, removing unnecessary access that could lead to thread corrosion—where compromised threads weaken overall security. Use role-based access controls to limit permissions to essential functions, preventing unauthorized modifications. Keep an eye on activity logs to detect unusual behavior early. By maintaining strict permissions, you minimize vulnerabilities that could cause leaks through weak points in your system. Consistent permission management also helps prevent thread corrosion, ensuring your union stays secure and functional. Stay proactive, and regularly assess your permission settings to protect your union and thread integrity.

Quick Fixes for Minor Leaks and Drips

When dealing with minor leaks and drips, quick fixes can save you time and prevent further damage. Addressing small issues early supports union safety and keeps thread maintenance simple. Here are four quick fixes:

- Tighten fittings gently to stop leaks without damaging threads.

- Apply pipe thread tape or sealant for a quick, lasting seal.

- Use a wrench carefully to avoid overtightening, which can cause leaks.

- Inspect unions regularly to catch early leaks and maintain thread integrity.

These steps help you manage minor leaks efficiently, minimize downtime, and maintain safe work conditions. Always prioritize proper thread maintenance to prevent leaks from worsening, and remember that quick fixes are temporary solutions. For persistent issues, consulting a professional is recommended.

When to Call a Professional for Union and Thread Issues

While minor leaks can often be handled with quick fixes, persistent or severe issues indicate it’s time to call in a professional. If you notice ongoing drips or water pooling around a union, don’t delay in seeking expert help. Proper union maintenance and leak detection are essential to prevent further damage. A professional plumber can accurately diagnose the problem, identify hidden leaks, and ensure the threads are properly sealed. Ignoring serious leaks can lead to costly water damage or compromised pipe integrity. When leaks persist despite your efforts, it’s best to rely on a trained technician who has the tools and experience to fix the issue efficiently. Knowing when to call a pro saves you time, money, and stress in the long run.

Frequently Asked Questions

How Do Leaks at Union Joints Affect Overall Plumbing System Integrity?

Leaks at union joints compromise the plumbing system’s integrity by causing water damage, corrosion, and pressure issues. You should focus on union joint maintenance and employ leak detection techniques like pressure testing and visual inspections to catch leaks early. Addressing leaks promptly ensures the system remains secure, prevents costly repairs, and maintains ideal flow. Regular checks and proper sealing at union joints are essential for long-lasting, reliable plumbing performance.

What Materials Are Most Resistant to Thread Corrosion and Leaks?

Think of your plumbing as a shield against water damage. You’ll want to choose stainless steel or brass for thread material because they offer exceptional corrosion resistance. These materials stand strong against rust and wear, keeping leaks at bay and your system secure. By selecting the right materials, you protect your plumbing’s integrity and avoid costly repairs, ensuring peace of mind with every connection you make.

Can Improper Thread Pitch Cause Leaks Over Time?

Yes, improper thread pitch can cause leaks over time. When the pitch doesn’t match correctly, it creates gaps or uneven contact, compromising the seal. This misalignment can lead to fluid or gas escaping, especially under pressure. To guarantee leak prevention, always verify the thread pitch matches specifications before assembly. Properly matched thread pitches provide a tight seal, reducing the risk of leaks and ensuring long-term reliability.

Are There Eco-Friendly Sealants Suitable for Union Threads?

Think of eco-friendly sealant options as the green guardians of your union thread maintenance. Yes, there are environmentally conscious sealants designed specifically for union threads that prevent leaks without harming the planet. These sealants are safe, effective, and sustainable choices, ensuring your connections stay tight over time. Using eco-friendly options not only protects the environment but also promotes long-lasting, reliable union thread maintenance, keeping your system running smoothly and sustainably.

How Often Should Union and Threaded Connections Be Inspected?

You should inspect union and threaded connections regularly as part of your union maintenance routine, ideally every 6 to 12 months. This inspection schedule helps you detect potential leaks, corrosion, or wear early, preventing costly repairs or failures. During each inspection, check for tightness, signs of damage, and proper sealing. Consistent inspections ensure your unions stay secure and functioning efficiently, reducing downtime and maintaining system integrity.

Conclusion

By understanding the basics of union leaks and threaded connections, you’re like a skilled mechanic who can spot trouble before it worsens. With simple tools and quick fixes, you can keep leaks at bay and save time and money. Remember, sometimes a minor drip signals a bigger issue—so don’t hesitate to call a pro if needed. Staying proactive keeps your plumbing flowing smoothly, just like a well-oiled machine.