Hidden costs of bypass valves often sneak in when they cause extra energy use, increase maintenance needs, or are poorly installed. If valves aren’t properly sized or maintained, you might face higher utility bills, equipment failures, or safety issues. To avoid these pitfalls, guarantee correct sizing, regular upkeep, and strategic placement. Keeping things optimized can save you money long-term—and there’s more to uncover if you explore further.

Key Takeaways

- Improper sizing or placement can cause pressure issues, increasing maintenance and repair costs.

- Neglecting regular inspection leads to corrosion, leaks, and premature valve failure.

- Using low-quality materials accelerates wear and escalates replacement expenses.

- Unoptimized valve operation wastes energy, raising utility bills over time.

- Poor system analysis and planning result in costly modifications and reduced equipment lifespan.

Increased Energy Consumption and Operational Costs

While bypass valves can help protect equipment, they often lead to increased energy consumption. When these valves bypass flow unnecessarily, your system works harder to compensate, reducing overall energy efficiency. This extra effort translates into higher utility bills and increased operational costs. Over time, the added energy use erodes potential cost savings, making your operations more expensive than they need to be. To avoid this, guarantee bypass valves are only engaged when absolutely necessary and regularly check their settings. Proper management helps minimize unnecessary flow bypasses, keeping energy consumption in check. Additionally, Waterpark facilities often rely on efficient fluid management systems to reduce operational costs and conserve energy. Ultimately, maintaining ideal system efficiency not only saves you money but also prolongs equipment lifespan, maximizing your investment and reducing long-term expenses.

Common Maintenance Challenges and Hidden Expenses

Regular maintenance of bypass valves is essential to prevent unexpected failures and costly repairs. If neglected, you may face issues like valve corrosion, which weakens components, or leakage that compromises system integrity. To keep your bypass valves in top shape, watch out for these common challenges:

- Valve corrosion: Regular inspections help catch corrosion early, preventing leaks and failures.

- Leakage: Ensure seals and gaskets are intact to avoid fluid leaks that increase operational costs.

- Inadequate lubrication: Proper lubrication reduces wear and extends valve lifespan.

- Scaling and debris buildup: Cleanings prevent blockages and maintain smooth operation.

Addressing these challenges promptly minimizes hidden expenses and keeps your system running efficiently. Proper maintenance not only saves money but also prolongs the life of your bypass valves.

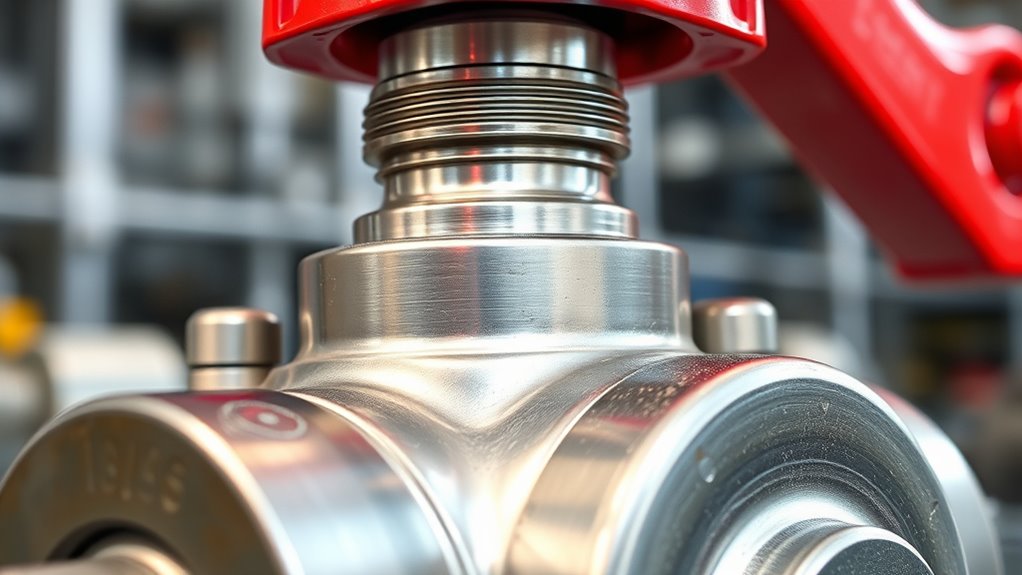

Risks of Improper Bypass Valve Sizing and Placement

Improper sizing and placement of bypass valves can lead to significant operational issues and increased costs. If the valve is too small, it won’t effectively divert flow, causing pressure buildup and potential equipment damage. Conversely, an oversized valve may cause frequent oscillations, increasing wear and tear. Incorrect placement can result in inefficient valve calibration, making it difficult to achieve ideal system performance. Installation pitfalls, such as neglecting proper support or misaligning the valve, can further compromise functionality. These issues not only lead to higher maintenance expenses but also create safety risks and system downtime. To avoid these problems, ensure precise sizing based on flow requirements and carefully consider placement for easy access and proper integration into the system. Additionally, understanding system dynamics can help in selecting the appropriate bypass valve specifications to optimize performance.

Strategies to Minimize Hidden Costs and Optimize Performance

Implementing proactive planning and thorough system analysis can substantially reduce hidden costs associated with bypass valves. To optimize performance, focus on proper installation techniques and careful material selection. Consider these strategies:

- Choose durable materials suited for your operating environment to prevent premature failure.

- Follow precise installation techniques to ensure the bypass valve functions correctly and minimizes maintenance.

- Conduct detailed system analysis beforehand, identifying potential pressure drops or flow issues that could lead to costly adjustments.

- Regularly review and update system components to maintain efficiency and avoid unexpected expenses.

These steps help prevent costly modifications, extend valve lifespan, and improve system reliability, ultimately saving you money over time.

Frequently Asked Questions

How Do Bypass Valves Impact Overall System Efficiency?

Bypass valves impact your overall system efficiency by regulating flow, ensuring the right amount of fluid moves through the system. Proper flow regulation minimizes energy loss and prevents equipment strain. However, if you neglect valve maintenance, it can cause blockages or leaks, reducing efficiency. Regular checks and upkeep help maintain ideal flow, prevent hidden costs, and keep your system running smoothly.

What Are Early Signs of Bypass Valve Failure?

You should watch for failure symptoms like unexpected pressure drops, unusual noises, or inconsistent system performance. These early signs indicate your bypass valve might be failing. Regular valve maintenance helps catch these issues early, preventing costly repairs. If you notice any of these symptoms, inspect the valve promptly and consider professional evaluation to avoid further system damage. Staying vigilant guarantees your system runs smoothly and efficiently.

Can Bypass Valves Cause System Pressure Fluctuations?

Ironically, your bypass valve’s malfunction can cause unpredictable system pressure fluctuations, making you think the entire setup is playing tricks. Yes, bypass valves can definitely cause pressure instability, especially when they fail or aren’t properly maintained. When they malfunction, they disrupt the flow, leading to inconsistent pressure levels. So, if you notice sudden pressure swings, check your bypass valve—it might be the sneaky culprit behind your system’s instability.

Are There Specific Industries More Prone to Bypass Valve Issues?

Certain industries, like oil and gas, chemical processing, and power generation, are more prone to bypass valve issues. You’ll face industry-specific challenges, such as high pressure or corrosive environments, that require rigorous maintenance practices. Regular inspections and timely replacements help prevent problems. Staying proactive with maintenance ensures bypass valves function correctly, reducing costly downtime and system failures across these sectors.

How Often Should Bypass Valves Be Inspected or Replaced?

You should inspect bypass valves regularly, ideally following your system’s maintenance schedule, which often recommends every 6 to 12 months. Use proper inspection techniques, such as checking for leaks, corrosion, or wear, and make certain they operate smoothly. Replace bypass valves if you notice persistent issues or after a specific lifespan—typically every 3 to 5 years—to prevent costly failures and maintain system efficiency.

Conclusion

By understanding these hidden costs and taking proactive steps, you can avoid falling into pitfalls that drain your resources. Proper sizing, placement, and maintenance are key to keeping your bypass valves working efficiently. Remember, a stitch in time saves nine—address issues early before they snowball into bigger, more expensive problems. Stay vigilant and informed, and you’ll keep your system running smoothly without surprises lurking around the corner.