Understanding valving layouts helps you control flow efficiently, improve safety, and simplify maintenance. Proper placement, like upstream or downstream, ensures pressure stability and quick isolation during repairs. Common configurations, such as series or parallel setups, match different system needs, while safety features like accessible valves prevent hazards. Balancing flow and preventing contamination keep systems running smoothly. If you want to master designing effective layouts, you’ll find valuable insights that can make your projects much easier to manage.

Key Takeaways

- Proper valve placement controls flow effectively, reducing pressure drops and enhancing system efficiency.

- Well-designed layouts enable quick isolation for maintenance and improve safety.

- Modular and standardized designs support future expansion and ease system modifications.

- Strategic valve configurations, like series or parallel, optimize flow management and redundancy.

- Clear labeling, accessibility, and documentation are essential for troubleshooting and operational safety.

Understanding the Basics of Valving Layouts

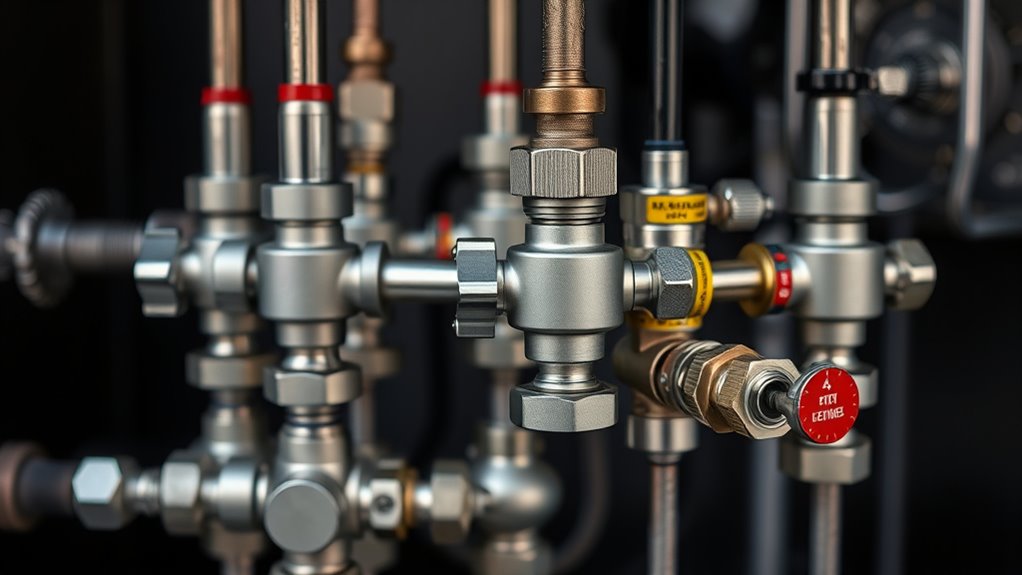

Understanding the basics of valving layouts is essential because they determine how fluid flows through a system. When you choose the right valve selection, you influence flow dynamics, which impacts efficiency and performance. Recognizing how valves are arranged helps you control pressure, direction, and volume effectively. Different layouts, such as series or parallel configurations, affect how fluid moves, so understanding these setups ensures you optimize system operation. Proper valving layout minimizes turbulence and pressure drops, making your system more reliable. By grasping these fundamental principles, you set a solid foundation for designing, troubleshooting, and maintaining fluid systems. Implementing best practices in valving layouts also involves understanding systematic testing to identify potential issues early and ensure optimal performance. Whether you’re working on industrial processes or plumbing, understanding flow dynamics through valving layouts is key to achieving precise control.

The Importance of Proper Valve Placement

Proper valve placement directly influences how effectively your system controls flow, pressure, and direction. When valves are correctly positioned, you achieve optimal flow management, reducing pressure drops and enhancing system efficiency. Poor placement can cause turbulence, uneven flow, or pressure loss, hampering performance and increasing wear. To maximize flow optimization, consider the following:

| Valve Placement | Effect on System |

|---|---|

| Upstream | Better pressure control |

| Downstream | Precise flow regulation |

| Near pumps | Protects equipment |

| Before branches | Balances flow distribution |

| Close to outlets | Accurate flow control |

Choosing the right valve placement ensures your system runs smoothly, saving energy and reducing maintenance costs. Proper placement is key to unlocking reliable, efficient operation.

Common Valving Configurations and Their Uses

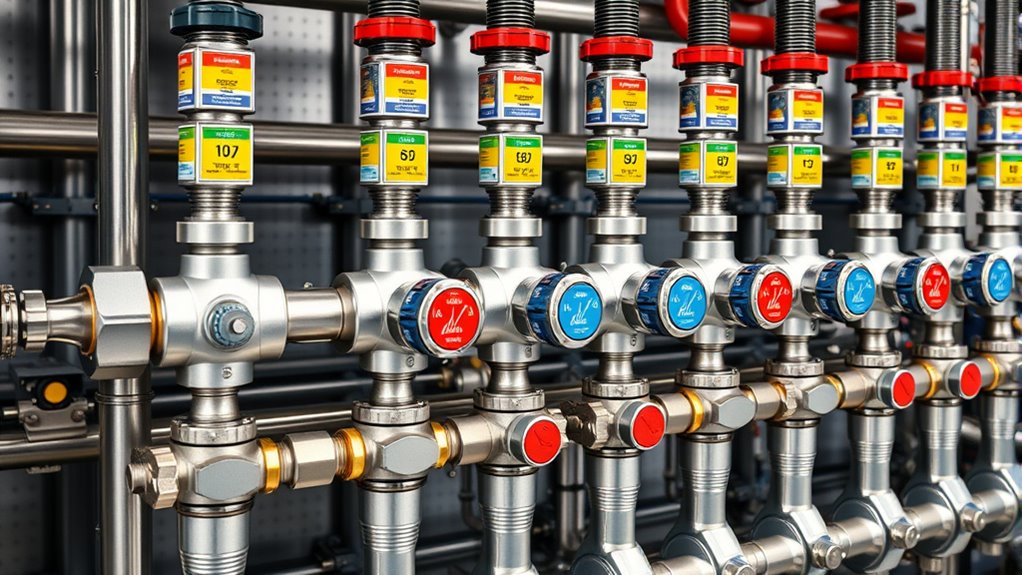

Different valving configurations serve specific functions within a system, allowing you to control flow, pressure, and direction effectively. For example, a simple shut-off valve is perfect for isolating sections, while a pressure-reducing valve ensures pressure regulation techniques are maintained downstream. When selecting valve size, consider flow requirements and system pressure to optimize performance and avoid issues like pressure drops or excessive wear. Common configurations include parallel setups for redundancy, series arrangements for staged pressure control, and bypass valves for maintenance. Each setup serves a distinct purpose, helping you manage system efficiency and safety. Understanding these configurations allows you to choose the right type and size of valve for your application, ensuring reliable operation and precise control over flow and pressure. Incorporating system organization into your planning can further enhance efficiency by making maintenance and adjustments more straightforward.

How to Ensure Safety and Accessibility in Valving Systems

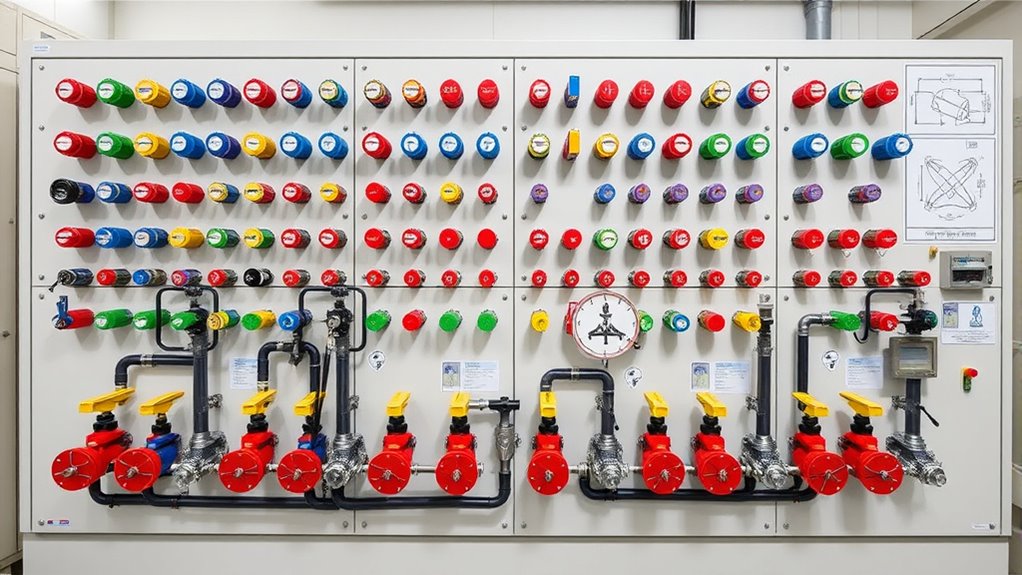

Ensuring safety and accessibility in valving systems requires careful planning and regular maintenance. Start by designing for ergonomic access, so operators can easily reach and operate valves without strain. Incorporate clear labeling and color coding to quickly identify critical components, especially emergency shutoff valves. Position emergency shutoff valves in visible, unobstructed locations to enable rapid response during emergencies. Use lever or handle designs that require minimal effort, reducing fatigue and improving control. Regular inspections guarantee valves function correctly and safety features remain intact. Train staff on proper operation and emergency procedures. Additionally, understanding the valving layout and its influence on system safety helps optimize overall performance. By prioritizing ergonomic design and accessible placement of safety features, you minimize risks and ensure quick, effective responses when needed.

Balancing Flow Control and System Efficiency

Achieving an ideal balance between flow control and system efficiency requires careful adjustment of valves and controls to match operational demands. Proper pressure regulation ensures consistent performance without wasting energy or risking damage. Flow balancing helps distribute resources evenly, preventing bottlenecks or overpressure issues. To optimize, consider these key points:

Balance flow control and system efficiency through precise valve adjustments and pressure regulation.

- Use pressure regulation valves to maintain stable system pressure

- Adjust flow control valves for precise flow balancing across zones

- Monitor system performance regularly for inefficiencies

- Avoid over-pressurizing to reduce strain on components

- Implement feedback controls to dynamically optimize flow and pressure

- Consulting security system best practices can help prevent system failures and ensure safety.

The Role of Isolation Valves in Maintenance and Safety

Isolation valves are vital for maintaining system safety by allowing you to shut off flow quickly during emergencies. They also make maintenance easier by providing safe access points to service specific sections without disrupting the entire system. Proper placement of these valves ensures both safety and efficient maintenance when needed. Additionally, implementing digital literacy and critical thinking skills in digital parenting helps children navigate online challenges responsibly and confidently.

Ensuring System Safety

When working on maintenance or troubleshooting, you rely on isolation valves to quickly shut off sections of your system and prevent accidents. Properly placed valves enhance safety by enabling immediate isolation during leaks or pressure issues. They also support pressure regulation by controlling flow and reducing risks of over-pressurization. Additionally, they play an essential role in leak detection, allowing you to isolate suspect areas without shutting down the entire system. Keep in mind:

- Quick isolation minimizes hazards during emergencies

- Isolating for leak detection ensures system integrity

- Valves help manage pressure fluctuations safely

- Proper valve placement prevents accidental releases

- Regular testing confirms they function correctly

Using isolation valves thoughtfully ensures safer operations, quick responses to issues, and maintains system integrity for long-term safety. For example, selecting a preppy dog name that reflects the system’s sophistication can enhance your operational environment.

Facilitating Maintenance Access

Proper placement of isolation valves not only enhances safety but also simplifies maintenance activities. When valves are positioned with easy access in mind, it becomes much easier to shut off sections of the system quickly. Ensuring valve accessibility means you can reach them through well-placed access panels or clear pathways, reducing downtime during repairs. Avoid hiding valves behind equipment or in cramped spaces, as this can delay maintenance and increase safety risks. Clear labeling and strategic locations help technicians identify and operate valves efficiently. Well-designed valving layouts facilitate quick isolation of system segments, minimizing disruption and ensuring safety during maintenance. Prioritizing accessible valve placement ultimately saves time and reduces potential hazards, making routine upkeep safer and more straightforward. Additionally, considering Hyundai Tuning options can influence component placement and accessibility for performance upgrades and maintenance.

Preventing Cross-Contamination With Strategic Valving

Have you considered how strategic valve placement can prevent cross-contamination in your system? Proper valving guarantees that different fluids or chemicals don’t mix unintentionally. By placing valves thoughtfully, you can:

- Isolate sections to contain spills or leaks

- Minimize fluid contact points for leak prevention

- Use chemically compatible materials to prevent reactions

- Create dedicated flow paths for specific substances

- Easily switch between cleaning and production modes

Taking these steps helps maintain chemical compatibility and reduces the risk of contamination. Strategic valving not only safeguards product integrity but also enhances safety and compliance. Ensuring valves are correctly positioned prevents cross-flow and keeps your system running smoothly. Proper valve placement is an essential aspect of designing an efficient, contamination-free operation.

Designing for Flexibility and Future Expansion

Strategic valving layouts should not only address current system needs but also accommodate future growth and changes. Incorporating modular design allows you to easily add or modify sections without overhauling the entire system. This flexibility is essential for future proofing, ensuring your setup can adapt as demands evolve. By planning for expansion now, you avoid costly reconfigurations later. Use standardized components and clear access points to streamline upgrades and troubleshooting. Think ahead about potential system expansions, and design your valving layout to support those developments seamlessly. This proactive approach keeps your system efficient and responsive, saving time and money in the long run. Ultimately, designing with adaptability in mind ensures your system remains robust and adaptable, no matter what the future holds.

Troubleshooting and Diagnosing Valving Issues

When valving issues arise, quick and accurate diagnosis is essential to minimize system downtime. Start by checking sensor integration, ensuring signals are correctly received and interpreted. Inspect valve automation components for stuck or misaligned parts that could cause malfunction. Use diagnostic tools to identify irregularities in pressure or flow. Listen for unusual noises that indicate internal damage or debris. Finally, verify that control signals match expected outputs. Additionally, understanding the vetted home theatre projector options can help optimize system performance.

- Confirm sensor signals are synchronized with system commands

- Test solenoids and actuators for proper operation

- Look for leaks or blockages in piping

- Check for electrical faults or wiring issues

- Use diagnostic software to pinpoint anomalies in valve control logic

Best Practices for Documenting and Standardizing Valving Layouts

To guarantee consistency, you need clear diagramming standards that everyone follows. Applying uniform labeling practices helps avoid confusion and errors. Additionally, implementing version control procedures keeps documentation accurate and up to date.

Clear Diagramming Standards

Clear diagramming standards are essential for ensuring that valving layouts are easily understood and consistently applied across projects. They help prevent miscommunication and streamline troubleshooting. To achieve this, focus on:

- Using consistent color coding to quickly identify valve types and functions

- Standardizing valve sizing to match system specifications

- Applying clear, uniform symbols for valves and connections

- Maintaining logical flow directions for easy reading

- Incorporating annotations that clarify operation and maintenance points

Consistent Labeling Practices

Consistent labeling practices guarantee that valving layouts are easily interpretable and maintainable across different projects and teams. Using clear, standardized labels helps avoid confusion, especially when multiple technicians or engineers work on the same system. Incorporate color coding to quickly identify valve functions or system sections, boosting efficiency and reducing errors. Maintain label consistency by using the same terminology, symbols, and formats throughout all documentation. This consistency ensures everyone understands the layout without second-guessing or misinterpretation. Regularly review and update your labeling standards to align with industry best practices. By prioritizing clear, consistent labels and thoughtful color coding, you make your valving layouts more accessible, reducing troubleshooting time and improving overall system reliability.

Version Control Procedures

Implementing effective version control procedures is essential for keeping valving layouts accurate and up-to-date across projects. Proper change management guarantees everyone works from the latest drawings, reducing errors and miscommunication. To achieve this, you should:

- Clearly label each version with dates and revision numbers

- Use a centralized system for document storage and updates

- Track all changes with detailed logs for accountability

- Establish approval workflows before implementing updates

- Regularly review and audit documents for consistency

Frequently Asked Questions

How Do I Select the Right Valve Types for Specific Applications?

To select the right valve types for specific applications, consider valve material selection to match your fluid or environment, ensuring durability and safety. Think about automation integration to streamline control and improve efficiency. You should evaluate pressure, temperature, and flow requirements, then choose valves like ball, butterfly, or check valves accordingly. Proper selection enhances performance, reduces maintenance, and aligns with your system’s operational goals.

What Are Common Mistakes to Avoid in Valving Layout Design?

You should avoid common mistakes like ignoring pressure drop impacts, which can reduce system efficiency, and neglecting valve accessibility, making maintenance difficult. Guarantee your valving layout minimizes unnecessary pressure drops by placing valves strategically. Also, design for easy access to valves, so you can service or replace them quickly without disrupting the entire system. Proper planning prevents costly errors and keeps your system running smoothly.

How Can I Optimize Valving for Energy Efficiency?

Think of your system as a finely tuned orchestra; to optimize energy efficiency, focus on pressure optimization and flow balancing. Adjust your valves to ensure even flow and prevent turbulence, which drains energy. Use smart control strategies to respond to real-time demand, reducing unnecessary pressure drops. This harmony minimizes waste, boosts efficiency, and keeps your system running smoothly like a well-conducted symphony.

What Standards or Codes Should I Follow for Valving Systems?

You should follow local building codes and industry standards like ASME and API for valving systems. Guarantee regulatory compliance by checking safety standards related to pressure ratings, materials, and installation procedures. Always stay updated on changes in regulations to maintain safety and efficiency. Properly documented compliance not only keeps you legal but also helps avoid costly penalties, ensuring your system operates reliably and safely over time.

How Do I Train Staff to Operate Complex Valving Layouts Safely?

You train staff to operate complex valving layouts safely through hands-on training, clear demonstrations, and consistent practice. Emphasize safety protocols at every step—wear protective gear, verify valve positions, and follow procedures precisely. Use real-world scenarios to build confidence, encourage questions for clarity, and reinforce safety culture. By actively engaging your team, you guarantee they understand the system, operate confidently, and prioritize safety in every action.

Conclusion

Mastering your valving layout isn’t just about mechanics—it’s about making systems safer, smarter, and simpler. By balancing boldness with best practices, you’ll build better, more reliable setups. Remember, strategic spacing, seamless safety, and straightforward standards safeguard your system’s success. So, step confidently, streamline your strategies, and let your valving layouts work wonders. With wise work and well-planned layouts, you’ll win in water, flow, and future-proofing!