To master advanced pH and corrosion safety, you need to understand how pH levels affect material reactions and identify early signs of corrosion like rust or cracks. Always use appropriate PPE, handle chemicals carefully, and store them securely. Regularly test and monitor pH levels with reliable tools, and respond quickly to spills or signs of deterioration. Continuing to explore these safety practices will help you safeguard equipment and ensure a safer environment.

Key Takeaways

- Maintaining proper pH levels prevents accelerated corrosion and material degradation in industrial equipment.

- Regular monitoring and calibration of pH testing devices ensure accurate detection of corrosive conditions.

- Using corrosion-resistant materials, coatings, and inhibitors extends equipment lifespan and reduces maintenance costs.

- Proper PPE, safe handling, and storage procedures minimize health risks associated with corrosive substances.

- Documenting inspections, incidents, and maintenance actions supports ongoing safety improvements and corrosion prevention.

Understanding Ph Levels and Their Impact on Materials

Understanding pH levels is essential because they directly influence how materials react to their environment. When pH levels are too acidic or alkaline, materials may corrode faster or degrade more quickly. To maintain ideal conditions, pH adjustment becomes vital, especially in industrial settings. Proper pH control can help prevent damage and prolong the lifespan of equipment. Using corrosion inhibitors is an effective strategy to protect surfaces from aggressive pH levels. These inhibitors form a protective film that minimizes metal interactions with corrosive agents. By monitoring and adjusting pH carefully, you reduce the risk of corrosion and preserve material integrity. Additionally, understanding the contrast ratio of your materials can help you assess how visual conditions might affect corrosion rates in sensitive environments. Whether in water treatment, manufacturing, or maintenance, understanding how pH impacts materials helps you choose the right methods to safeguard your assets.

Recognizing Signs of Corrosion and Its Causes

How can you tell if corrosion is starting to develop? Look for visible signs like rust, discoloration, or pitting on surfaces. You might also notice weakened areas or flaking material. These are clear indicators that corrosion is taking hold, which can compromise safety and equipment integrity. To improve corrosion prevention, regularly inspect your materials and consider proper material selection—choosing corrosion-resistant alloys or coatings can delay or prevent damage. Keep an eye out for:

- Rust spots or discoloration

- Cracks or flaking surfaces

- Unusual buildup or corrosion products

Recognizing these signs early helps you address problems before they escalate. Understanding the causes—such as exposure to moisture, acids, or improper materials—can guide you in making smarter choices for long-term durability. Additionally, implementing protective measures like asset division strategies, such as using corrosion-resistant materials or coatings, can significantly extend the lifespan of your equipment.

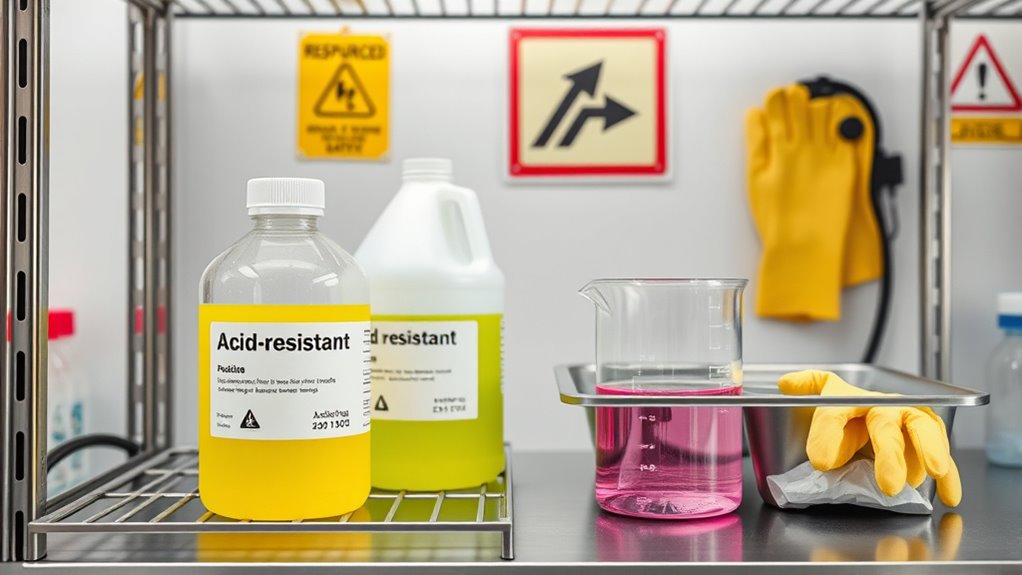

Personal Protective Equipment (PPE) for Handling Ph and Corrosive Substances

When dealing with corrosion and acidic substances, wearing proper personal protective equipment (PPE) is vital to guarantee safety. You should always wear protective gloves made of chemical-resistant materials to prevent skin contact with corrosive agents. These gloves act as a barrier, reducing the risk of burns or irritation. Additionally, respiratory masks are indispensable when working with fumes or aerosols that can be harmful if inhaled. Ensure your mask fits properly and is rated for chemical vapors. PPE not only shields you from immediate hazards but also minimizes long-term health risks. Always inspect your equipment before use, and replace damaged gear immediately. By properly equipping yourself with protective gloves and respiratory masks, you considerably reduce the danger associated with handling pH and corrosive substances. Using security systems to monitor hazardous areas can further enhance safety by alerting you to potential breaches or unsafe conditions.

Safe Handling and Storage of Acidic and Alkaline Materials

Handling and storing acidic and alkaline materials safely is essential to prevent accidents and health hazards. You must always consider chemical compatibility to ensure containers and storage environments are suitable for each substance. Follow strict storage guidelines, such as keeping acids and bases separate to avoid dangerous reactions. Use clearly labeled, corrosion-resistant containers designed for specific chemicals. Store these materials in cool, well-ventilated areas away from incompatible substances and ignition sources. Regularly inspect storage areas for leaks or corrosion, and keep emergency equipment nearby. Additionally, understanding the properties of corrosion can help in selecting appropriate materials for storage containers. Choose containers made from compatible materials. Label all containers clearly with contents and hazards. Store in designated, secure areas away from personnel and equipment.

Proper Techniques for Testing and Monitoring Ph Levels

Accurate testing and continuous monitoring of pH levels are vital for maintaining safe and effective chemical processes. You should regularly use reliable pH meters or test strips to check the solution’s acidity or alkalinity. Proper calibration of your equipment guarantees precise readings, which are indispensable for effective pH adjustment and chemical neutralization. When testing, avoid contamination by rinsing electrodes with distilled water and handling them carefully. Monitoring pH levels over time allows you to detect shifts that could indicate corrosion risks or the need for corrective action. Consistent data helps you maintain ideal conditions, guaranteeing safety and process efficiency. Remember, timely pH adjustment prevents corrosion damage and supports proper chemical neutralization, safeguarding both personnel and equipment. Additionally, implementing automation in data analysis can enhance the accuracy and responsiveness of your monitoring system.

Emergency Response Procedures for Corrosion Incidents

When a corrosion incident occurs, your first priority is to contain the spill immediately to prevent further damage. You should then document the incident thoroughly and report it to the proper authorities. Clear, quick actions help minimize risks and guarantee proper follow-up. Additionally, understanding corrosion basics can aid in assessing the severity and necessary response measures.

Immediate Containment Strategies

Immediate containment is critical to minimizing damage and preventing further corrosion escalation during an incident. You should act quickly to control the spread of the corrosive substance and protect personnel and equipment. Start by implementing spill containment measures, such as using dikes or absorbent materials, to limit the spread. Then, apply chemical neutralization when appropriate to reduce the corrosive nature of the spill. Ensure you wear proper protective gear to avoid exposure. Promptly evacuate non-essential personnel from the area. Always have emergency response kits on hand, equipped with neutralizers and spill containment supplies, to facilitate rapid action. Quick, decisive steps can considerably reduce the severity of the incident and safeguard your facility. Incorporating safety protocols and proper training can further enhance response effectiveness during such incidents.

Reporting and Documentation

Effective reporting and thorough documentation are vital components of an emergency response to corrosion incidents. When you document the event, record details like the location, extent of damage, and materials involved. This information guides effective chemical neutralization efforts and helps determine if corrosion inhibitors are needed to prevent further damage. Report incidents immediately to guarantee quick action and coordinate with safety teams. Keep detailed logs of response steps, including the application of neutralizing agents or corrosion inhibitors used. Proper documentation also supports regulatory compliance and future prevention strategies. Your accurate reports enable continuous improvement in safety protocols, reducing the risk of recurring corrosion issues. Staying precise and prompt in documentation helps protect personnel, equipment, and the environment from ongoing corrosion hazards. Additionally, understanding the hours of operation for related beauty stores can aid in planning emergency supplies or support during off-hours.

Maintenance Practices to Minimize Corrosion Risks

Regular maintenance is essential for minimizing corrosion risks in pH and corrosion-sensitive environments. Consistent inspection helps identify early signs of deterioration, allowing you to act before problems escalate. Using corrosion inhibitors can protect metal surfaces and extend equipment lifespan. Applying coating applications creates a barrier against moisture and corrosive agents, reducing damage. To stay ahead, consider these practices:

Regular maintenance and protective measures are key to preventing corrosion damage.

- Regularly inspect and clean surfaces to prevent buildup of corrosive substances

- Use corrosion inhibitors tailored to your environment for added protection

- Apply protective coatings correctly, ensuring full coverage and adhesion

- Implement proper storage procedures to prevent exposure to moisture and corrosive elements.

Frequently Asked Questions

How Does Temperature Influence Corrosion Rates in Different Environments?

You notice that temperature fluctuations directly impact corrosion rates, varying with environmental factors. Higher temperatures speed up chemical reactions, increasing corrosion, especially in moist or salty environments. Conversely, lower temperatures slow reactions, reducing corrosion risk. Always consider how ambient temperature interacts with other environmental factors, like humidity or pollutants, to assess corrosion potential accurately. Managing temperature and environmental conditions helps prevent damage and prolong the lifespan of your equipment.

What Are the Long-Term Effects of Corrosion on Structural Integrity?

Corrosion weakens your structures over time by causing metal fatigue and coating degradation. As corrosion progresses, it compromises the material’s strength, increasing the risk of cracks and failures. You may notice reduced load-bearing capacity and increased vulnerability to environmental stresses. Long-term, this deterioration can lead to costly repairs or catastrophic collapse, emphasizing the importance of regular inspections and protective coatings to preserve structural integrity and prevent safety hazards.

Are There Environmentally Friendly Methods to Neutralize Corrosive Spills?

You can confidently counter corrosive spills with eco-friendly neutralization methods that minimize environmental impact. Use natural neutralizers like baking soda or lime to safely stabilize acids, following proper spill response procedures. This approach promotes pollution prevention, prioritizes planet protection, and prevents harmful harm. By choosing sustainable solutions, you stay safe while safeguarding the environment, supporting a cleaner, greener, and more conscientious approach to managing corrosive spills effectively and ethically.

How Often Should Ph Monitoring Equipment Be Calibrated?

You should calibrate your pH sensor regularly to guarantee monitoring equipment accuracy. Typically, calibration is recommended every 1 to 4 weeks, depending on usage and environmental conditions. Frequent calibration helps maintain precise readings and detects potential sensor drift early. Always follow the manufacturer’s guidelines for calibration intervals, and use proper calibration solutions. This proactive approach ensures your pH sensor remains reliable and effective in monitoring corrosive spills or other applications.

Can Corrosion Be Completely Prevented With Current Technologies?

Corrosion can’t be entirely prevented with current technologies, but you can greatly reduce its impact. Using corrosion inhibitors and applying protective coatings creates barriers that slow down or stop corrosion processes. Regular maintenance and monitoring are essential to guarantee these protections work effectively. While no method guarantees complete prevention, combining these strategies helps extend equipment lifespan and improves safety by minimizing corrosion-related failures.

Conclusion

By understanding pH levels, recognizing corrosion signs, and practicing safe handling, you safeguard yourself, your team, and your equipment. Wearing proper PPE, monitoring pH regularly, and following emergency procedures keep risks at bay. Maintaining your systems, storing materials securely, and staying informed ensure safety and longevity. Stay vigilant, stay prepared, and stay safe—because knowledge, caution, and consistency are your best defenses against corrosion and chemical hazards.