To troubleshoot flow rate and pressure drop issues effectively, understand how system design, pipe size, and obstructions influence fluid movement. Watch for subtle signs like fluctuating pressure or vibrations, and use precise tools to diagnose problems. Keep in mind, poor layouts and buildup can cause unexpected losses. Regular inspections and early detection prevent bigger failures. If you keep these points in mind, you’ll uncover key insights to optimize your system and avoid common pitfalls.

Key Takeaways

- Proper system design, including pipe sizing and layout, minimizes turbulence and pressure drops, ensuring efficient flow.

- Regular maintenance and inspection help detect obstructions, corrosion, and buildup causing unexpected pressure loss.

- Accurate measurement tools and calibration are crucial for reliable flow rate and pressure drop diagnostics.

- Recognizing signs like pressure fluctuations, vibrations, and flow irregularities enables early troubleshooting.

- Consulting professionals when issues persist ensures precise diagnostics and prevents long-term system inefficiencies.

Understanding the Basics of Flow Rate and Pressure Drop

Understanding the basics of flow rate and pressure drop is essential for troubleshooting fluid systems effectively. You need to grasp how flow dynamics influence the movement of fluids through pipes and components. Flow rate measures how much fluid passes a point over time, while pressure drop indicates the loss of pressure as fluid travels, often due to resistance. Pressure modeling helps you predict these drops, giving insight into system performance. Recognizing how flow behaviors change with different pipe sizes, bends, or obstructions allows you to anticipate issues before they escalate. For example, changes in pipe diameter can significantly affect flow and pressure. By understanding these core principles, you can identify where pressure losses might occur and optimize your system for better efficiency. Mastering flow dynamics and pressure modeling is your foundation for successful troubleshooting.

Common Causes of Unexpected Pressure Loss

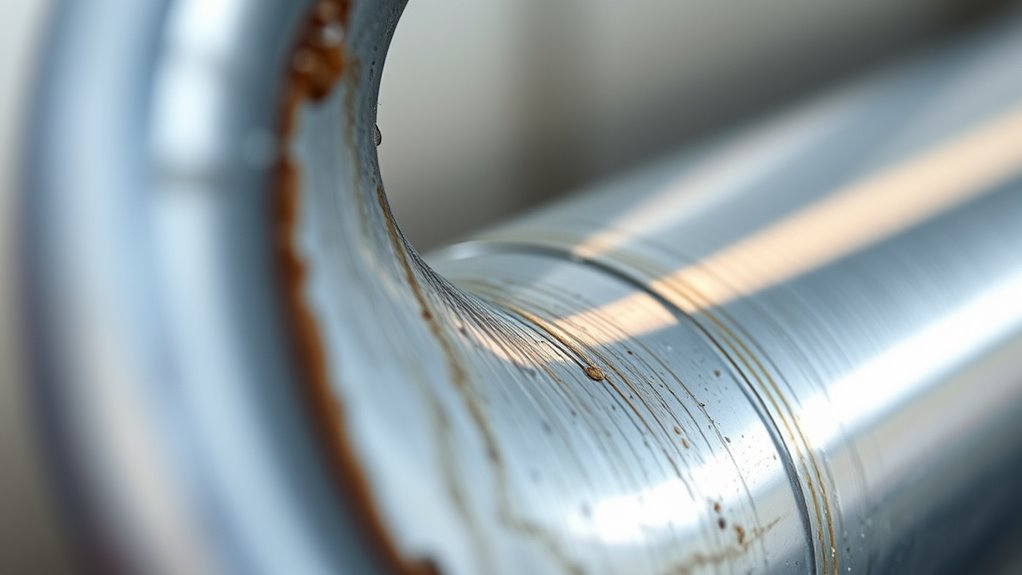

Unexpected pressure loss often signals underlying issues within your fluid system that require quick identification. One common cause is flow obstructions, such as debris or buildup that restricts flow and increases resistance. These blockages can occur anywhere in the system, from valves to narrow passages, causing sudden drops in pressure. Pipe corrosion is another major culprit; over time, corrosion can thin pipe walls or create rough surfaces that reduce flow efficiency. Rust and mineral deposits inside pipes create additional friction, making it harder for fluid to pass through smoothly. Recognizing these issues early helps prevent further damage and system failure. Regular inspections and maintenance are key to catching flow obstructions and corrosion before they lead to significant pressure drops. Additionally, understanding the role of material durability can help select pipes and components that resist corrosion and buildup, ensuring longer system life.

Recognizing Subtle Signs of System Inefficiency

Sometimes, your system shows signs of inefficiency that aren’t immediately obvious but can lead to bigger problems if ignored. You might notice subtle flow anomalies or pressure fluctuations that signal underlying issues. These signs often go unnoticed but are critical for early detection and troubleshooting. Recognizing these signs early can be crucial for implementing data-driven strategies, which help in making informed decisions to optimize system performance. Pay close attention to these clues, as they often indicate hidden inefficiencies. Flow anomalies can suggest blockages or leaks, while pressure fluctuations might point to valve problems or pump issues. Recognizing these subtle signs early helps prevent major failures and keeps your system running smoothly. Stay vigilant, and don’t dismiss small irregularities—they’re often the first warning of deeper trouble.

Tools and Techniques for Accurate Troubleshooting

To troubleshoot flow rate and pressure drops accurately, selecting the right tools is vital. You need precise instruments, proper calibration, and regular maintenance to guarantee reliable readings. Applying effective data analysis techniques helps you interpret results and pinpoint issues quickly. Incorporating awareness of air quality concerns can further refine troubleshooting strategies by understanding how pollutants and airflow disruptions impact system performance.

Precise Instrument Selection

Selecting the right instruments is crucial for accurately diagnosing flow rate and pressure drop issues. Proper sensor selection guarantees you get precise readings, which is essential for troubleshooting. When choosing sensors, consider flow type, range, and compatibility with your system. Valve sizing also plays a significant role; selecting the correct valve size prevents pressure drops and maintains system efficiency. Using the right tools minimizes errors and saves time during diagnosis. Focus on high-quality, calibrated instruments tailored to your specific application. Remember, inaccurate measurements can lead to misdiagnosis and costly mistakes. To optimize your troubleshooting process, pay close attention to sensor specifications and valve sizing guidelines. This ensures you gather reliable data, enabling informed decisions and effective solutions. Additionally, understanding the performance metrics of your equipment helps in diagnosing issues more accurately.

Calibration and Maintenance

Effective calibration and maintenance are essential for ensuring your flow rate and pressure drop measurements stay accurate over time. Following proper calibration procedures helps you identify and correct measurement deviations, maintaining instrument precision. Regular calibration checks should be part of your maintenance schedules, preventing drift that can lead to incorrect troubleshooting. Use certified calibration tools and document each calibration to track performance trends. Maintenance involves inspecting and cleaning sensors, fittings, and connectors to prevent buildup or corrosion that could skew readings. Establish routine maintenance intervals based on manufacturer recommendations and operating conditions. Staying diligent with calibration procedures and maintenance schedules ensures your instruments provide reliable data, reducing errors and improving troubleshooting accuracy. Proper care keeps your flow and pressure measurements consistent and trustworthy. Additionally, understanding the role of contrast ratio in image quality can help optimize visual data interpretation during troubleshooting processes.

Data Analysis Techniques

Utilizing the right data analysis tools and techniques is essential for accurate troubleshooting of flow rate and pressure drop issues. You should leverage statistical analysis to identify patterns and anomalies in your measurements, helping you pinpoint the root causes quickly. Data visualization plays a vital role by turning complex data into clear, actionable insights, making it easier to interpret trends and correlations. To optimize your troubleshooting, consider these techniques:

- Applying statistical analysis to detect outliers and variability

- Using data visualization tools like graphs and charts for real-time insights

- Implementing trend analysis to monitor changes over time and predict potential issues

- Incorporating emotional support strategies to stay focused and resilient during complex troubleshooting processes

Mastering these data analysis techniques empowers you to diagnose problems more effectively, saving time and reducing costly errors.

The Role of System Design in Troubleshooting Challenges

System design plays a crucial role in troubleshooting flow rate and pressure drop issues because it directly influences how fluid moves through the system. Poor system integration can create unexpected resistance points, causing pressure drops and reduced flow. When your system isn’t optimized, it may have inefficient pipe layouts, unnecessary bends, or mismatched components that hinder performance. Design optimization ensures that the system works smoothly, with proper pipe sizing, minimal turbulence, and consistent flow paths. By understanding how your system’s design affects fluid dynamics, you can identify potential problem areas quickly. A well-thought-out design simplifies troubleshooting, reduces downtime, and improves overall efficiency. Remember, proactive system integration and design optimization are key to minimizing flow and pressure issues before they become major problems. Additionally, paying attention to system materials can influence flow resistance and longevity, further enhancing system performance.

Preventive Measures to Minimize Troubleshooting Time

Implementing preventive measures is essential for reducing troubleshooting time in flow rate and pressure drop issues. By proactively monitoring system performance, you can catch problems early and avoid prolonged downtimes. Regular inspections help identify flow rate fluctuations before they escalate, while tracking pressure drop patterns highlights early signs of blockages or leaks. Maintaining equipment and cleaning filters prevents buildup that causes pressure inconsistencies. Additionally, documenting system behavior over time creates a baseline for detecting anomalies quickly. Utilizing essential oil properties in maintenance routines can also promote equipment longevity and optimal performance.

When to Seek Expert Assistance

Knowing when to seek expert assistance is essential to prevent minor flow rate and pressure drop issues from turning into costly downtime. If troubleshooting limits are reached despite your efforts, it’s time to call in the pros. Expert advice can identify underlying problems faster and prevent recurring issues. Additionally, understanding flow rate and pressure drop dynamics can help you communicate more effectively with specialists. Consider this table to gauge when to escalate:

| Symptom | Action | When to Seek Help |

|---|---|---|

| Persistent pressure drops | Review system, then consult experts | Troubleshooting stalls |

| Unusual flow fluctuations | Attempt basic fixes; then get advice | No clear cause after initial check |

| Equipment vibrations | Check for obstructions; seek guidance | Vibrations persist or worsen |

| Unresponsive gauges | Calibrate or replace; consult experts | No improvement after adjustments |

| System inefficiency | Analyze with specialist insight | Widespread or recurring issues |

Trust your judgment—when limits are met, expert advice saves time and money.

Frequently Asked Questions

How Does Fluid Viscosity Affect Pressure Drop Calculations?

Viscosity effects markedly impact pressure drop calculations because higher viscosity increases flow resistance. When fluid is more viscous, it resists motion more, leading to greater pressure drops for the same flow rate. You need to account for this by adjusting calculations, as ignoring viscosity effects can cause underestimating the pressure drop. Always consider fluid viscosity to guarantee accurate pressure drop assessments and to optimize system performance effectively.

Can Temperature Fluctuations Impact Flow Rate Measurements?

Yes, temperature effects can impact flow rate measurements by altering fluid viscosity and density. As temperature fluctuates, your measurement accuracy may suffer because these changes affect how flow sensors and instruments read the fluid’s movement. To guarantee precise readings, you should monitor temperature regularly and consider calibration adjustments or temperature compensation techniques, helping you maintain reliable data despite temperature variations.

What Role Do Pipe Material and Surface Roughness Play?

Did you know that pipe material and surface roughness can increase pressure drops by up to 50%? Your choice of pipe material markedly impacts flow rate, especially if corrosion occurs, leading to rough surfaces that hinder flow. Using incompatible materials accelerates corrosion and roughness, making flow less efficient. To optimize performance, select corrosion-resistant materials suited for your fluid and maintain smooth pipe surfaces, reducing pressure drops and ensuring consistent flow.

How Do Transient Conditions Influence Pressure Stability?

Transient conditions cause pressure fluctuations and transient oscillations that directly impact pressure stability. When flow rates change suddenly, these oscillations can amplify, leading to unstable pressure levels. You might notice pulsations or sharp drops, which challenge consistent system operation. To maintain stability, you should monitor for transient events, use dampers or accumulators, and optimize system design to reduce the effects of these transient phenomena.

Are There Industry Standards for Acceptable Pressure Loss?

Yes, there are industry benchmarks for acceptable pressure loss. You should consider pressure loss classification standards, which help you determine if your system’s pressure drop falls within acceptable limits. These benchmarks vary by industry and application, but generally, you aim for minimal pressure loss to maintain efficiency. Comparing your system’s pressure drop to these standards can help you identify when corrective actions are needed to optimize flow and reduce energy costs.

Conclusion

Think of your system as a river, where flow and pressure are its heartbeat. When obstacles arise, they signal deeper currents beneath the surface. By understanding these signs and nurturing your system’s health, you become the skilled navigator, steering clear of hidden whirlpools. Remember, sometimes the most intricate eddies demand expert insight. Trust your knowledge, stay vigilant, and keep the flow steady—your system’s liveliness depends on it.