Preventing channeling in media tanks isn’t about packing media tightly; it’s about ensuring even water flow through proper media distribution and tank design. Tightly packed media can actually cause flow restrictions, leading to dead zones. Proper maintenance, regular backwashing, and adjusting media depth help keep flow uniform. Good inlet and outlet placements are essential too. If you want to know more about common myths and effective strategies, keep exploring these key points in plain English.

Key Takeaways

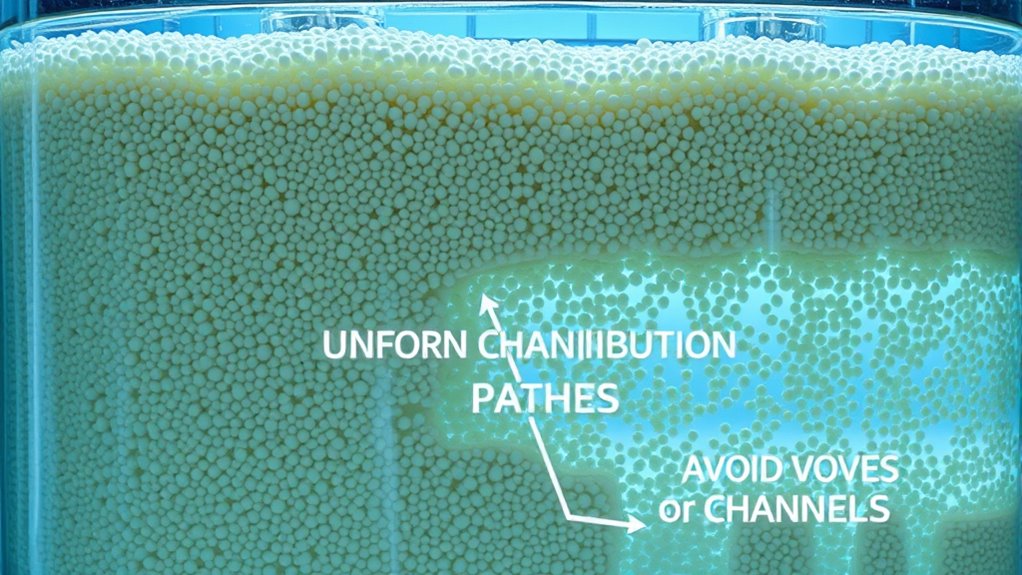

- Proper media packing and even distribution prevent water from bypassing filter media, reducing channeling risks.

- Correct inlet and outlet placement promote uniform flow, avoiding stagnation and dead zones.

- Regular maintenance, including backwashing and media inspection, keeps flow consistent and prevents clogging.

- Using appropriate media particle size balances debris removal with water flow, minimizing channel formation.

- Adjusting media depth and tank design helps ensure stable pressure and flow, reducing uneven flow paths.

What Is Channeling and Why Does It Matter?

Channeling is the practice of communicating with spirits or spiritual entities, often through a person known as a channel or medium. In media tanks, “channeling” refers to uneven flow paths where water bypasses the filter media, reducing filtration efficiency. It matters because it can compromise biological filtration, which relies on stable environments for beneficial bacteria, and chemical absorption, where filter media remove toxins. When water channels, these processes become less effective, leading to poor water quality and potential tank issues. Understanding how channeling affects water flow helps you prevent dead zones and guarantees your filtration system works as intended. Proper media placement and avoiding tight packing can minimize channeling, maintaining ideal biological and chemical filtration for a healthy tank. Additionally, optimizing flow dynamics within the tank ensures even water distribution and reduces the risk of channeling occurring.

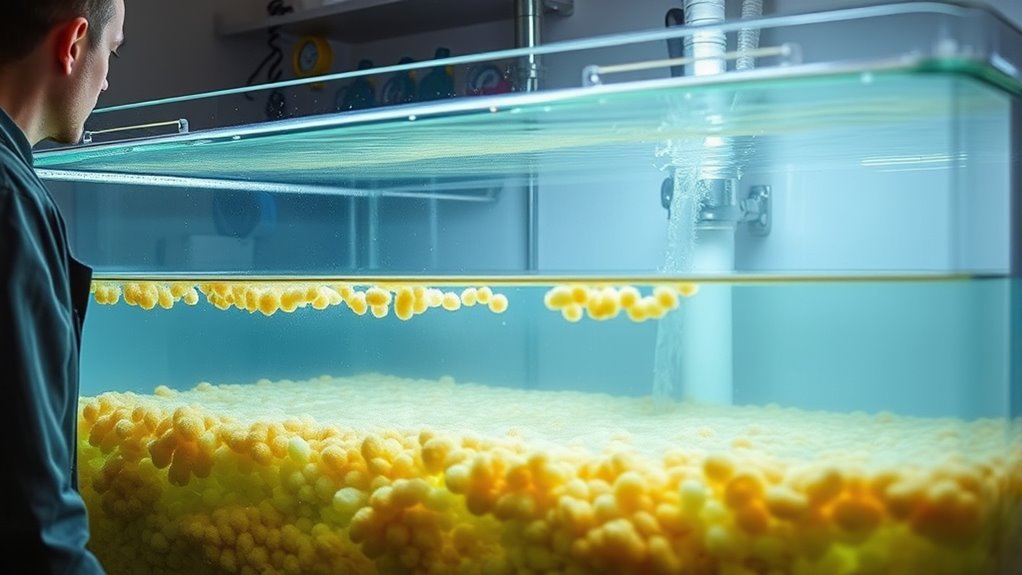

Common Misunderstanding: Packing Media Tightly Prevents Channeling

Many aquarists believe that packing media tightly will prevent water from creating shortcuts and bypassing the intended flow paths. However, this isn’t true. A tightly packed media bed can actually hinder flow uniformity, causing uneven water distribution and potential channeling. When media is too dense, water struggles to pass through, leading to zones of low flow and bypassed areas. Proper flow depends on adequate space for water to move freely, not just packing media tightly. Additionally, understanding the importance of media bed structure can help optimize filtration performance. Here’s a quick comparison:

| Tightly Packed Media | Ideal Media Bed | Loose Packing |

|---|---|---|

| Causes flow restrictions | Promotes flow uniformity | Allows even flow |

| Risk of channeling | Prevents shortcuts | Maintains even water movement |

| Reduces filtration efficiency | Maximizes contact | Ensures consistent flow |

| Difficult to clean | Easier maintenance | Easier to access media |

| Higher pressure drop | Balanced flow | Lower pressure drop |

Focus on flow, not just tight packing.

The Truth About Media Distribution and Uniformity

Achieving uniform media distribution is essential for ideal filtration, yet it’s often misunderstood. Proper distribution ensures consistent media saturation, allowing water to flow evenly through the tank. If media isn’t evenly spread, channeling can occur, reducing filtration efficiency. To prevent this, consider media compatibility with your system’s chemical environment; incompatible media can break down or clog, disrupting uniformity. Mixing media types or stacking them improperly can cause uneven flow paths. Regularly inspecting and adjusting media placement helps maintain even saturation and flow. Remember, uniform distribution isn’t just about filling the tank—it’s about ensuring each particle interacts optimally with water, providing effective filtration and extending media lifespan. Correct media placement and chemical compatibility are key to achieving and maintaining this balance. Additionally, understanding Hyundai Tuning options can help optimize your system for better performance and longevity.

Does Increasing Media Depth Reduce the Risk?

Increasing media depth influences flow and pressure distribution within the tank, which can impact the risk of channeling. Finding the most suitable depth involves balancing pressure effects and flow consistency to prevent uneven media movement. Let’s explore how these factors interact to determine if deeper media layers actually reduce operational risks. For instance, understanding signs of spoilage in media can help prevent blockages and improve overall process safety.

Media Depth and Flow

While deeper media layers might seem like a straightforward way to reduce risks, the relationship isn’t always so simple. Increasing media depth affects media gravity, which influences how particles settle and flow turbulence, impacting flow patterns. Deeper media can sometimes promote stable flow, but in other cases, it can cause uneven flow or dead zones. To better understand the effect, consider:

- Greater media depth can increase flow turbulence if flow paths become uneven.

- Media gravity influences how particles move, potentially affecting channeling.

- Deeper media may reduce surface flow velocity, but not necessarily eliminate channeling.

- Excessive depth might cause dead zones where flow stagnates, increasing risks.

Ultimately, ideal media depth balances flow stability and turbulence to minimize channeling.

Pressure Distribution Effects

Deeper media layers can alter pressure distribution within the system, but this doesn’t automatically mean the risk of issues like channeling decreases. Increasing media depth changes how pressure imbalances develop across the tank, which can influence flow turbulence. If pressure isn’t evenly distributed, it may cause uneven flow paths, creating zones where water moves faster or slower. This uneven flow can promote channel formation rather than prevent it. Simply adding more media doesn’t guarantee a more stable flow or reduce channeling risk. Instead, you might experience increased flow turbulence, which can worsen flow inconsistencies. Consequently, understanding how pressure distribution shifts with media depth helps you recognize that deeper isn’t always better unless other factors are optimized to maintain even pressure and smooth flow.

Optimal Depth Strategies

Adding more media depth doesn’t automatically lower the risk of channeling; in fact, it can sometimes make the problem worse if pressure distribution becomes uneven. Deeper media layers may hinder proper flow, affecting chemical reactions essential for algae control. To maximize depth strategies, consider these points:

- Ensure uniform pressure distribution to promote consistent chemical reactions and prevent dead zones.

- Balance media depth with flow rate to enhance algae control without creating channels.

- Use proper media types suited for deeper tanks to avoid uneven settling that can lead to channeling.

- Regularly monitor flow patterns and adjust media depth accordingly to maintain effective algae control and reduce channeling risks.

- Incorporate skilled management techniques to optimize flow and media placement, further reducing the potential for channeling.

Adjusting media depth thoughtfully supports effective chemical reactions and minimizes uneven flow, keeping your tank functioning optimally.

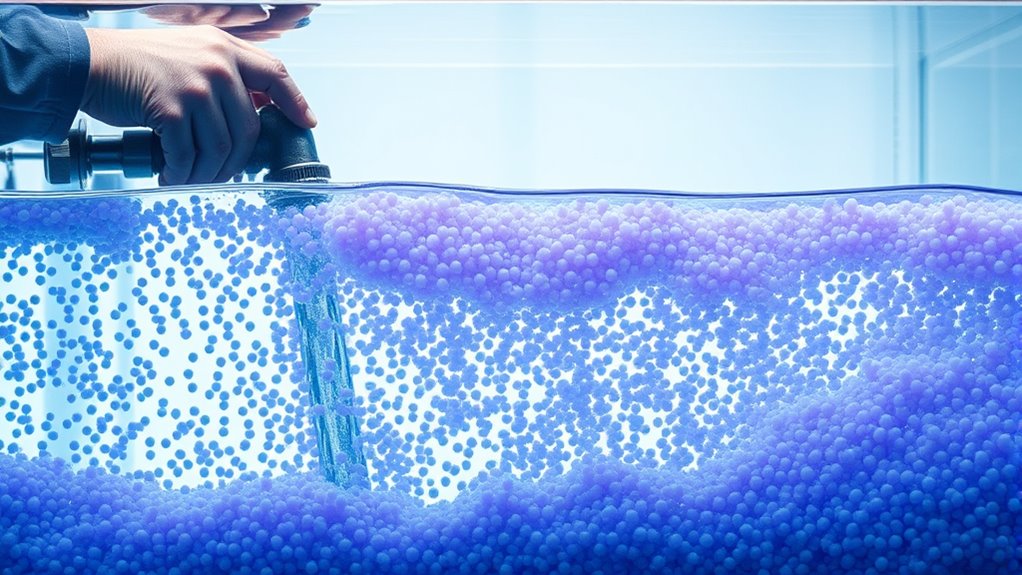

The Role of Proper Backwashing and Maintenance

Proper backwashing and regular maintenance are crucial for keeping your media tanks functioning efficiently. By performing thorough backwashing, you remove trapped debris and prevent clogging, which helps maintain proper flow and reduces channeling risks. During maintenance, check the chemical balance to ensure ideal filtration conditions and prevent media degradation. If the media becomes too worn or clogged, media replacement is necessary to preserve filtration effectiveness and prevent channeling paths from forming. Consistent upkeep also involves inspecting for uneven media distribution and addressing any buildup that could cause flow issues. Staying on top of these tasks minimizes the chances of channeling, extending your tank’s lifespan and ensuring consistent water quality. Proper maintenance isn’t just routine; it’s essential for optimal tank performance. Regularly monitoring media support structures can also prevent flow disruptions before they develop.

Myth: Using Smaller Media Particles Always Improves Filtration

Using smaller media particles might seem like a quick fix for better filtration, but it can actually reduce flow and cause channeling issues. When particles are too fine, water struggles to pass evenly through the media, risking uneven filtering. Ultimately, there’s a limit to how much smaller particles improve filtration without compromising system performance. Additionally, improper confined spaces can exacerbate these problems by trapping debris and reducing overall efficiency.

Particle Size and Flow

Many believe that choosing smaller media particles always leads to better filtration, but this isn’t necessarily true. Particle flow depends on media porosity, which affects how water moves through the tank. Smaller particles can reduce flow rates and increase the risk of clogging, disrupting even distribution. Conversely, larger media allow better flow, preventing channeling and ensuring effective filtration. To optimize filtration:

- Understand that smaller particles can restrict particle flow, causing uneven media packing.

- Recognize that media porosity influences water movement and overall efficiency.

- Balance particle size with flow requirements to prevent clogging or bypass.

- Avoid assuming that smaller always equals better; instead, consider flow dynamics and media structure.

- Incorporating proper media selection based on flow characteristics ensures a more reliable filtration system.

Choosing the right particle size maintains proper flow and reduces channeling risks, ensuring consistent filtration performance.

Channeling Risks Increase

While smaller media particles are often thought to enhance filtration, they can actually increase the risk of channeling within the filter media. When media particles are too fine, they tend to compact more easily, reducing media turnover and creating preferential flow paths. This uneven flow allows water to bypass much of the media, decreasing filtration effectiveness. Additionally, smaller particles can lead to compatibility issues with certain chemicals, causing media degradation or clumping that worsens channeling. Using media that’s too fine without considering flow dynamics and chemical compatibility can trap debris in specific channels instead of filtering uniformly. To prevent this, select media with appropriate particle sizes and guarantee proper media turnover, maintaining even flow and maximizing filtration without risking channel formation. Proper media selection and flow management are essential for effective filtration and preventing channeling.

Filtration Efficiency Limits

Is smaller media particle size always better for filtration? Not necessarily. While smaller particles can trap finer debris, they often reduce media flow and filtration capacity. Excessively fine media can clog quickly, increasing backpressure and limiting overall media flow. This can lead to uneven media distribution and channeling, decreasing filtration effectiveness.

Consider these points:

- Smaller particles increase surface area but may cause rapid clogging.

- Reduced media flow limits the volume of water processed over time.

- Filtration capacity can decline if media becomes oversaturated or blocked.

- Proper particle size balances debris removal with maintaining ideal flow and capacity.

Understanding these limits helps prevent over-reliance on tiny media, ensuring effective filtration without compromising media flow or efficiency.

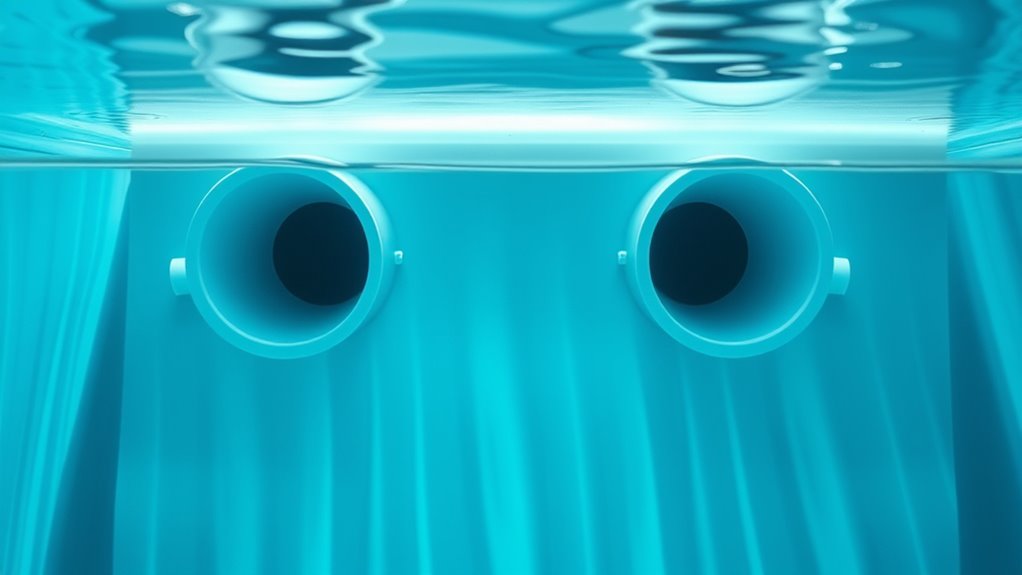

How Tank Design and Inlet/Outlet Placement Affect Flow

Tank design and the placement of inlets and outlets directly influence how flow behaves inside the system. Your choice of tank shape affects flow patterns, with rectangular tanks often prone to uneven flow if not carefully managed. Baffle placement is vital; correctly positioned baffles help direct flow evenly across the media bed, reducing dead zones and preventing channeling. Proper inlet and outlet locations ensure water moves smoothly through the tank, avoiding short-circuiting or stagnation zones. If you place inlets at the tank bottom or outlets at the top without consideration, you risk creating areas of flow stagnation. Overall, thoughtful tank design, strategic baffle placement, and ideal inlet/outlet positioning work together to promote uniform flow, minimize channeling, and extend media life. Flow distribution plays a critical role in maintaining effective media contact and system longevity.

Tips for Effective Media Tank Management and Prevention Strategies

To keep your media tank operating efficiently, regular maintenance and monitoring are essential. Proper management ensures ideal media chemistry and helps prevent channeling. Here are four tips to improve your strategy:

Regular maintenance and monitoring keep your media tank efficient and channeling-free.

- Regularly inspect media for clumping or uneven distribution, which can cause flow issues.

- Adjust chemical additives carefully based on water quality tests to maintain proper media chemistry.

- Use media circulation equipment effectively to promote uniform flow and prevent dead zones.

- Schedule routine cleaning and media replacement to avoid buildup that can lead to channeling.

Implementing these practices helps maintain consistent flow, enhances filtration performance, and minimizes the risk of channeling in your media tank.

Frequently Asked Questions

How Can I Identify if Channeling Is Occurring in My Media Tank?

You can identify if channeling is happening in your media tank by monitoring sensor readings for uneven distribution or sudden changes. Additionally, perform a visual inspection to look for irregular flow patterns, such as uneven media movement or stagnant zones. If sensor data shows inconsistent readings or the visual check reveals flow gaps, it’s a clear sign that channeling is occurring, and you should take steps to correct it.

Are There Specific Media Types That Are More Resistant to Channeling?

Imagine pouring dry sand and then a thick, gelatinous substance—your choice of media types substantially impacts resistance levels to channeling. Generally, denser media like resin or certain plastics are more resistant to channeling because their structure prevents flow gaps. Conversely, loose or granular media, such as gravel or sand, tend to have lower resistance levels, making them more prone to channeling. Choosing the right media type helps guarantee even flow and avoids issues.

What Are Signs of Uneven Media Distribution During Operation?

You’ll notice signs of uneven media distribution during operation through irregular media flow, such as inconsistent pressure or flow rates. During tank inspection, look for areas with media buildup or voids that suggest poor flow. If you observe channeling or media segregation, it indicates uneven distribution. Addressing these issues early helps prevent channeling and guarantees the media functions effectively, maintaining ideal tank performance.

Can External Environmental Factors Influence Channeling Risks?

Think of your media tank like a boat in a river—external influences like temperature, humidity, or vibrations can cause uneven media flow, increasing channeling risks. Environmental impact matters because changes outside the tank, such as weather or plant vibrations, can disturb media distribution. External influences aren’t just minor; they can markedly affect tank performance, making it essential to monitor and control environmental factors to prevent uneven media flow.

How Often Should Media Be Replaced to Prevent Channeling?

You should replace media regularly, typically every 6 to 12 months, to guarantee effective channeling prevention. Frequent media replacement helps maintain proper flow and prevents buildup that can cause channeling issues. Keep an eye on media condition, and don’t wait until it looks worn or clogged. Consistent media replacement ensures your tank operates efficiently, reduces risks of channeling, and extends the lifespan of your media system.

Conclusion

Think of your media tank as a well-orchestrated dance floor. When everyone moves smoothly, the filtration flows effortlessly, and your system stays healthy. By understanding myths and applying proper maintenance, you prevent channeling from becoming the unwelcome guest that throws off the rhythm. Keep your media evenly distributed, avoid shortcuts, and stay vigilant. With the right care, your tank will perform like a perfectly synchronized dance, keeping your water crystal clear and thriving.