Quick connect fittings make installations faster and easier, letting you connect and disconnect components without tools, ideal for frequent maintenance. They reduce downtime and minimize the risk of leaks or improper connections. On the other hand, threaded connections offer high security and are better suited for high-pressure or vibration-heavy systems, but they require more effort and time to install or disconnect. Balancing convenience and system security is key—continue exploring to find the best fit for your needs.

Key Takeaways

- Quick connect fittings enable fast, tool-free installation and disassembly, reducing setup and maintenance time.

- Threaded connections provide high security and are suitable for high-pressure or vibration-prone systems.

- Quick connect fittings minimize the risk of leaks and improper connections, enhancing system reliability.

- Threaded fittings may require tools and effort for installation and disassembly, especially if corroded.

- The choice depends on balancing ease of use versus long-term security and stability.

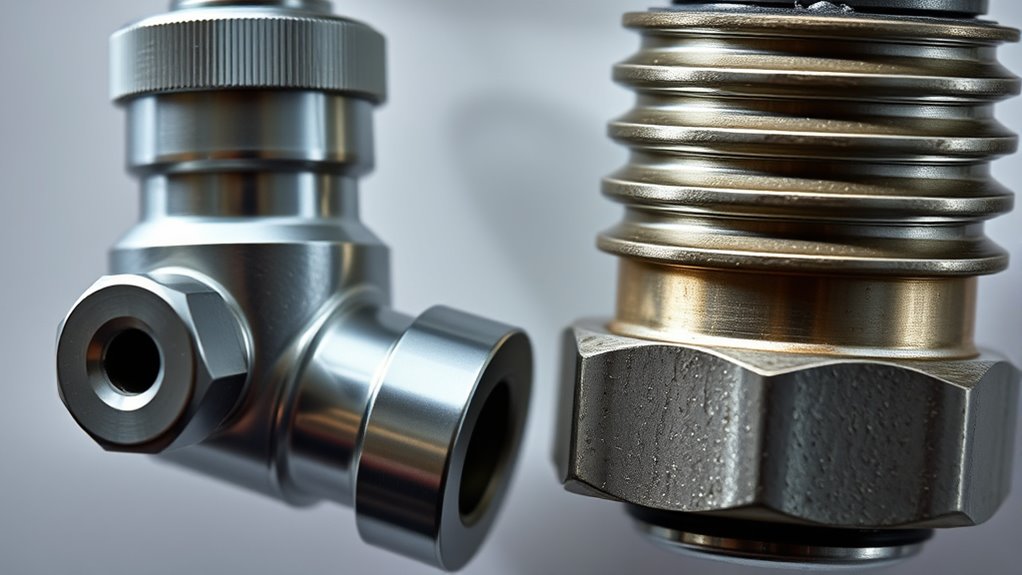

When choosing between quick connect fittings and threaded connections, understanding their differences is essential for ensuring efficient and reliable fluid transfer. Each option offers unique advantages and potential drawbacks, depending on your specific application. Quick connect fittings are designed for fast, tool-free connections, making installation ease a significant benefit. You can connect and disconnect these fittings quickly, saving you time during setup or maintenance. They’re especially useful in situations where equipment needs frequent connection changes or where minimizing downtime is critical. Their design often includes push-to-connect features, which eliminate the need for threading or sealing compounds, simplifying the process even further. This ease of installation not only speeds up your work but also reduces the chances of improper connections, which can lead to leaks or system failure.

Quick connect fittings enable fast, tool-free connections, reducing installation time and simplifying maintenance.

On the other hand, threaded connections are more traditional and involve screwing fittings together using threads. While they might require more effort initially—sometimes needing thread sealant or tape to prevent leaks—they offer a high degree of security once properly installed. If you’re working in environments with high pressure or vibration, threaded connections tend to stay secure over time, maintaining system integrity. However, their installation isn’t as straightforward as quick connect fittings. You’ll need tools, and the process can be time-consuming and requires careful attention to avoid cross-threading or damaging the threads. Maintenance simplicity is another factor; threaded fittings can be more challenging to disconnect, especially if tight or corroded, which may require additional effort and sometimes even replacement of parts.

In terms of maintenance and long-term reliability, quick connect fittings shine in their simplicity. They’re designed for easy disconnection, which means inspecting, cleaning, or replacing parts becomes less cumbersome. This quick disassembly reduces downtime and simplifies routine maintenance tasks. Conversely, threaded connections might need more effort to disconnect and reassemble, especially if corrosion or debris has accumulated. Over time, threaded fittings can loosen or degrade, requiring re-tightening or replacement, making them less convenient for frequent maintenance tasks.

Ultimately, your choice depends on your priorities. If you value installation ease and maintenance simplicity, quick connect fittings offer a clear advantage, especially for applications that demand quick setup and frequent disassembly. However, if your system needs maximum security against leaks under high pressure or vibration, threaded connections might be the better choice despite their slightly more complex installation and maintenance processes. Balancing these factors will help you select the best fitting type for your specific needs.

Frequently Asked Questions

Can Quick Connect Fittings Handle High-Pressure Applications Effectively?

Quick connect fittings can handle high-pressure applications effectively if they’re made from compatible materials like stainless steel or brass. You need to verify the connection security is tight and reliable to prevent leaks or disconnections under pressure. Always check the manufacturer’s specifications for pressure ratings. When properly selected and installed, quick connect fittings offer a convenient, secure option for high-pressure systems without sacrificing performance.

Are Quick Connect Fittings Suitable for Outdoor or Corrosive Environments?

Quick connect fittings are generally suitable for outdoor and corrosive environments if they’re made from corrosion-resistant materials like stainless steel or plastic. They offer good weather durability, resisting rust and corrosion over time. However, verify you select fittings specifically designed for harsh conditions, as some cheaper options may degrade quickly. Proper maintenance and choosing high-quality fittings help ensure longevity and reliable performance in outdoor, corrosive environments.

How Do Maintenance and Repair Differ Between Quick Connect and Threaded Systems?

You’ll find that quick connect fittings make maintenance easier because you can disconnect and reconnect components swiftly without tools. Repairs are often simpler, reducing downtime. In contrast, threaded systems usually involve more complex repair processes, requiring tools and more time to disassemble and reassemble. If ease of maintenance is your priority, quick connect fittings are the better choice, but threaded connections might offer more durability for long-term use.

What Are the Cost Implications of Choosing Quick Connect Fittings Over Threaded Connections?

Choosing quick connect fittings is like planting seeds for long-term savings. While the initial purchase may be higher, you save on labor costs and reduce downtime during installation or repairs. Over time, these fittings can lower maintenance expenses, making them more economical. So, the upfront investment pays off, translating into smoother operations and fewer costly disruptions, ultimately saving you money in the long run.

Do Quick Connect Fittings Require Special Tools for Installation and Disassembly?

You don’t need special installation tools for quick connect fittings, making installation quick and simple. Disassembly is just as easy, often requiring only your hands or basic disassembly tools. Unlike threaded connections, which may need wrenches, quick connect fittings are designed for tool-free or minimal-tool operation. This convenience saves time and effort during setup and disassembly, making them ideal for applications where quick, hassle-free connections are essential.

Conclusion

Choosing between quick connect fittings and threaded connections is like picking between a zipper and buttons. Quick connects snap together effortlessly, saving time like a zipper sliding smoothly, ideal for frequent setups. Threaded connections, like buttons, offer durability but take more effort to secure. If you’re working on a project that needs speed, quick connects are your go-to. But for long-term, sturdy holds, threaded connections are the reliable choice that won’t let you down.