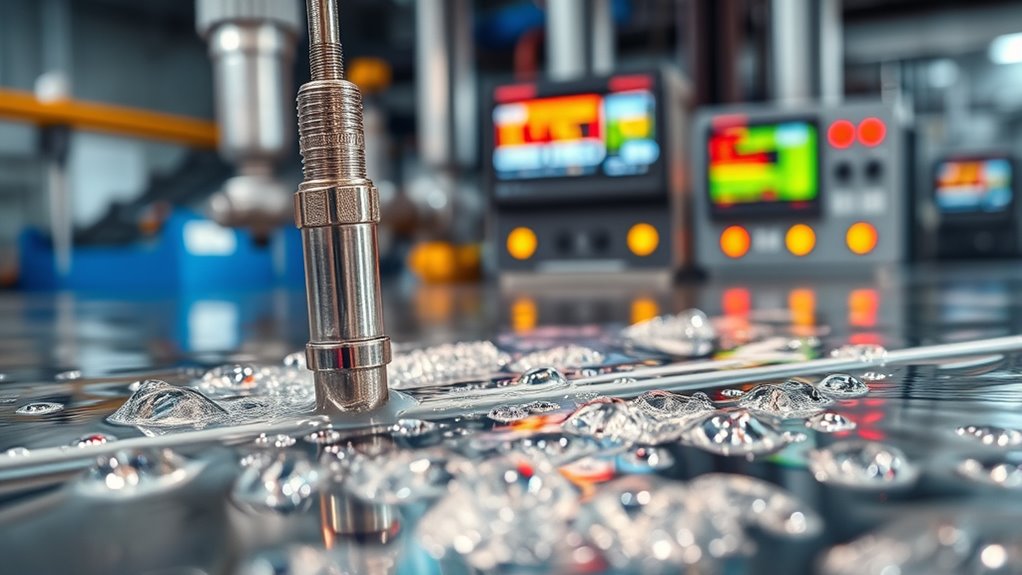

Neglecting proper pH control and corrosion troubleshooting can hide costly damage to your equipment, often going unnoticed until repairs become urgent. Poor measurements, equipment corrosion, and delayed actions lead to increased maintenance costs, efficiency losses, and system failures. To avoid these hidden expenses, you need accurate sensors, regular calibration, and proactive maintenance strategies. Continue to explore how early detection and proper management can save you money and extend your equipment’s lifespan.

Key Takeaways

- Inaccurate pH measurements can lead to improper chemical dosing, accelerating corrosion and causing costly equipment damage.

- Regular calibration and sensor maintenance prevent measurement errors that hide early signs of corrosion.

- Ignoring pH fluctuations increases the risk of unseen corrosion hotspots, resulting in unexpected repairs and replacements.

- Delayed troubleshooting worsens corrosion, leading to higher repair costs and potential system downtime.

- Proactive monitoring and early intervention extend equipment lifespan and reduce long-term operational expenses.

The Impact of Ph Imbalances on Equipment Longevity

When the pH level of your water deviates from its ideal range, it can considerably shorten the lifespan of your equipment. An improper pH can accelerate corrosion, leading to costly repairs and replacements. To prevent this, you should perform regular pH adjustment, ensuring the water remains within safe limits. Using corrosion inhibitors alongside pH adjustment helps protect metal surfaces from rust and deterioration. These inhibitors form a protective barrier, reducing the corrosive effects of acidic or alkaline water. Maintaining proper pH levels minimizes the risk of corrosion-related damage, extending your equipment’s operational life. Regular monitoring and timely pH correction are essential steps to safeguard your investment and ensure long-term performance. Choosing the right airless paint sprayer can also help minimize equipment stress caused by improper water conditions.

Common Signs of Corrosion and Their Hidden Costs

Recognizing the signs of corrosion early can save you from costly repairs and system failures. Watch for pH fluctuation, which often indicates corrosion activity, especially if the pH shifts unexpectedly. Common corrosion patterns include rust-colored deposits, pitting, or scaling on equipment surfaces. These visual clues signal underlying issues that might not be immediately obvious but can lead to significant damage if ignored. Corrosion can cause leaks, reduce efficiency, and shorten equipment lifespan. Addressing these signs promptly helps prevent hidden costs associated with extensive repairs or replacements. Additionally, implementing effective fraud prevention tools can help safeguard your systems from external threats. By staying alert to pH fluctuations and corrosion patterns, you can catch problems early, minimize downtime, and save money in the long run. Early detection is key to maintaining system integrity.

How Inaccurate Measurements Lead to Costly Mistakes

Inaccurate measurements of pH or corrosion indicators can lead you to make poor maintenance decisions, ultimately costing more in repairs and downtime. If your sensors lack accuracy, you might overlook early signs of corrosion or treat issues unnecessarily. Poor measurement consistency causes you to second-guess data and potentially apply incorrect solutions, which can accelerate equipment deterioration. When sensors drift or provide unreliable readings, you risk overusing chemicals, under-treating corrosive conditions, or bypassing necessary maintenance. These costly mistakes often stem from neglecting sensor calibration or failing to verify measurement accuracy regularly. Ensuring your sensors deliver precise, consistent data helps you identify problems early, avoid unnecessary repairs, and keep operations running smoothly. Reliable measurements are essential for cost-effective corrosion management. Additionally, understanding the best practices for juice extraction can help maintain the accuracy of your sensors by preventing contamination and ensuring clean measurement environments.

The Role of Proper Calibration in Preventing Damage

Proper calibration guarantees your sensor readings stay accurate, preventing costly mistakes. Consistent measurement standards help maintain reliability over time, avoiding drift that can cause damage. When you prioritize calibration, you protect your equipment and save money in the long run. Incorporating sound design principles can also improve the accuracy of audio equipment, ensuring optimal functionality.

Accurate Sensor Readings

Because sensors provide critical data for pH and corrosion monitoring, ensuring their readings are accurate is essential to prevent costly damage. Proper calibration directly impacts sensor accuracy and measurement reliability. To achieve this, you should:

- Regularly verify calibration with standard solutions to catch drift early.

- Maintain clean sensors to prevent contamination that skews readings.

- Use correct calibration procedures specific to your sensor type for consistency.

- Understanding sensor technology can help troubleshoot and improve calibration practices.

Consistent Measurement Standards

Maintaining consistent measurement standards is essential for effective pH and corrosion monitoring, and proper calibration plays a key role in this process. When you guarantee standardization consistency, your measurement accuracy improves, reducing errors that can lead to costly damage. Regular calibration aligns your sensors with known standards, preventing drift and maintaining reliable readings. To help you stay on track, consider this calibration checklist:

| Step | Action | Frequency |

|---|---|---|

| Standardization | Use certified calibration solutions | Weekly or monthly |

| Documentation | Record calibration results | Each session |

| Sensor Check | Inspect and clean sensors | Before calibration |

| Equipment Verification | Verify calibration equipment accuracy | Annually |

| Adjustment | Fine-tune sensors as needed | After calibration |

Consistent measurement standards ensure your system’s integrity, preventing costly corrosion issues. Proper calibration is a fundamental aspect of maintaining measurement accuracy and system longevity.

Prevents Calibration Drift

Consistent measurement standards rely heavily on regular calibration, but even with strict procedures, sensors can drift over time. This drift affects pH stabilization and can compromise corrosion inhibition efforts. To prevent damage, you should:

- Regularly calibrate sensors with fresh standards to maintain accuracy.

- Monitor for signs of drift, such as inconsistent pH readings or fluctuating corrosion rates.

- Use calibration techniques that account for temperature variations, ensuring precise pH measurements.

- Implement quality control measures to verify calibration effectiveness and detect potential issues early.

Unseen Effects of Corrosion on System Efficiency

Corrosion often goes unnoticed until it causes a noticeable decline in system performance, yet its unseen effects can substantially reduce efficiency. As corrosion develops, it hampers heat transfer, increases friction, and causes blockages, all of which strain your system. Early corrosion detection is vital because these hidden issues diminish system efficiency without obvious signs. Over time, corrosion can thin pipes, create leaks, and cause components to work harder, leading to higher energy consumption and increased operating costs. By regularly inspecting for corrosion and maintaining proper pH levels, you can catch these problems early. Understanding corrosion mechanisms can help in implementing more effective preventative measures. Staying proactive ensures your system runs smoothly, maximizing efficiency and preventing costly downtime caused by unseen corrosion damage.

Costly Repairs Resulting From Neglected Ph Control

When you neglect proper pH control, your equipment faces increased damage and wear. This oversight can lead to costly repairs and more frequent maintenance. Addressing pH issues early helps you save money and extend the life of your system. Using appropriate microphone technology can also prevent sound quality issues caused by corrosion or improper calibration.

Increased Equipment Damage

Neglecting pH control can lead to severe equipment damage, often resulting in costly repairs. When pH levels aren’t maintained, harmful chemical reactions occur inside your system, accelerating corrosion and degrading components. Poor sensor accuracy can cause incorrect pH readings, leading to improper adjustments and further damage. To avoid this, focus on:

- Regular calibration of pH sensors to ensure accurate readings.

- Monitoring chemical reactions that can produce corrosive byproducts.

- Implementing pH control strategies that prevent extreme acidity or alkalinity.

Ignoring these factors allows corrosive conditions to develop unchecked, damaging pumps, valves, and heat exchangers. Over time, this damage becomes extensive, forcing you into expensive repairs and replacements. Proper pH management is essential to protect your equipment from avoidable harm.

Higher Maintenance Costs

Failing to maintain proper pH levels often leads to costly repairs, as equipment endures increased wear and damage over time. When the pH balance is off, corrosion prevention becomes more difficult, accelerating equipment deterioration. Neglecting pH control can cause corrosion hotspots, weakening pipes, pumps, and other essential components. These issues often require frequent repairs or replacements, driving up maintenance costs considerably. By keeping a close eye on pH levels and ensuring proper balance, you can minimize corrosion risks and extend equipment lifespan. Proper pH control isn’t just about water quality—it’s a crucial factor in reducing higher maintenance costs and ensuring operational efficiency. Regular monitoring and corrosion prevention techniques play a vital role in maintaining system integrity.

Preventative Maintenance Strategies to Save Money

Implementing preventative maintenance strategies can substantially reduce the hidden costs associated with pH imbalances and corrosion. Regularly monitoring and adjusting water treatment helps maintain proper chemical balancing, preventing costly damage. To maximize savings, focus on these key actions:

- Schedule routine water testing to identify pH fluctuations early.

- Use automated chemical dosing systems for precise adjustments.

- Inspect and clean equipment regularly to prevent buildup and corrosion.

The Risks of Delayed Troubleshooting and Diagnosis

When you delay troubleshooting, damages can quickly escalate, leading to higher repair costs. System downtime increases, disrupting operations and costing you more in the long run. Plus, safety risks grow as issues go unnoticed, putting personnel in danger.

Escalating Damage Costs

Delaying troubleshooting and diagnosis in pH and corrosion issues often leads to rapidly escalating damage, increasing repair costs and downtime. Without timely action, corrosion can worsen quickly, causing structural weakening and equipment failure. To prevent this, focus on:

- Neglecting corrosion prevention measures can lead to costly repairs.

- Failing to maintain proper pH stabilization accelerates corrosion damage.

- Ignoring early warning signs makes repairs more complex and expensive.

Increased System Downtime

Delayed troubleshooting and diagnosis of pH and corrosion issues can substantially increase system downtime, disrupting operations and reducing productivity. When problems go unnoticed, equipment may run outside ideal pH balance, accelerating corrosion and causing unexpected failures. This leads to costly repairs and unplanned shutdowns. To prevent this, prioritize quick diagnostics and regular monitoring. Understanding the following factors can help you avoid extended outages:

| Factor | Impact on Downtime | Mitigation Strategy |

|---|---|---|

| pH imbalance | Corrosion accelerates | Regular pH checks, adjustments |

| Corrosion development | Equipment failure | Consistent corrosion prevention |

| Detection delay | Prolonged damage | Implement real-time sensors |

| Maintenance response time | Extended system outages | Schedule proactive maintenance |

Safety Risks Rise

Neglecting timely troubleshooting of pH and corrosion issues can substantially increase safety hazards for personnel and equipment. Delayed diagnosis can lead to dangerous chemical imbalances and equipment failures. When pH monitoring is ignored, you risk:

- Chemical safety breaches from unexpected releases or reactions.

- Increased corrosion that weakens pipes and tanks, risking leaks or bursts.

- Elevated risk of toxic exposure for workers handling malfunctioning systems.

These hazards not only threaten safety but also cause costly repairs and downtime. Proper, proactive pH monitoring helps you identify issues early, reducing the risk of accidents. Addressing corrosion promptly ensures safer operations and minimizes the chance of hazardous chemical incidents. Don’t wait—timely troubleshooting is your best defense against rising safety risks.

Investing in Quality Monitoring Tools for Long-Term Savings

Investing in high-quality monitoring tools might seem like an upfront expense, but it pays off by catching pH and corrosion issues early before they cause costly damage. Reliable sensors with enhanced longevity reduce the need for frequent replacements, ensuring consistent performance over time. Accurate monitoring is essential for identifying subtle changes in water chemistry, helping you address problems before they escalate. High-quality tools provide precise readings, which lead to better decision-making and prevent unnecessary maintenance or repairs. While initial costs may be higher, the long-term savings from fewer sensor failures, improved accuracy, and early detection outweigh the investment. Ultimately, investing in durable, accurate monitoring tools helps you maintain system integrity and reduce hidden costs associated with corrosion and pH management.

Best Practices for Early Detection and Cost Reduction

Implementing proactive monitoring practices is essential for detecting pH fluctuations and corrosion early, which can substantially cut down on costly repairs. By staying ahead of problems, you can perform timely pH correction and corrosion prevention measures. To maximize these benefits, consider these best practices:

- Regularly schedule pH testing to identify deviations promptly.

- Use automated sensors for real-time monitoring, enabling immediate responses.

- Maintain detailed logs to track trends, helping forecast issues before they escalate.

Early detection allows you to implement targeted pH correction and corrosion prevention strategies, reducing the risk of widespread damage. This proactive approach minimizes downtime, repairs, and operational costs, ultimately safeguarding your equipment and investments. Staying vigilant with these practices helps you manage corrosion risks effectively and keeps your system running smoothly.

Frequently Asked Questions

How Does Ph Fluctuation Affect Corrosion Rates Over Time?

When pH fluctuates, it affects corrosion rates by disrupting pH stability, making metals more prone to damage over time. Lower pH levels accelerate corrosion, while higher pH can slow it down, but instability causes inconsistent protection. To guarantee effective corrosion prevention, maintain a stable pH level, monitor regularly, and adjust as needed. This proactive approach prevents hidden costs and extends the lifespan of your equipment.

What Are the Hidden Costs of Ignoring Minor Ph Deviations?

Ignoring minor pH deviations can lead to significant hidden costs. You might face increased corrosion, which causes costly damage and shortens equipment lifespan. These issues result in higher maintenance challenges, requiring frequent repairs and replacements. Over time, the cost implications add up, impacting your operational efficiency and budget. Addressing small pH fluctuations early helps you minimize these hidden expenses, ensuring smoother operations and better long-term savings.

Can Improper Calibration Cause Equipment Failures Unnoticed?

Improper calibration is like a faulty compass; it can cause equipment failures to slip by unnoticed. When calibration accuracy suffers, your equipment’s reliability drops, increasing the risk of undetected malfunctions. Over time, these issues can escalate, leading to costly repairs or downtime. Regularly calibrate your instruments to guarantee precise readings, maintain equipment reliability, and prevent small problems from becoming major failures.

How Does Corrosion Impact System Efficiency Beyond Visible Damage?

Corrosion reduces system efficiency by compromising pH stability, leading to increased energy consumption and equipment wear. Even if you don’t see visible damage, corrosion can cause leaks, blockages, and reduced heat transfer. Proper corrosion mitigation keeps pH levels balanced, preventing unseen deterioration. This proactive approach guarantees your system runs smoothly, reduces downtime, and saves you money by avoiding costly repairs and efficiency losses caused by hidden corrosion effects.

What Are the Long-Term Financial Benefits of Early Troubleshooting?

Addressing issues early saves you up to 30% on maintenance costs over time. By troubleshooting corrosion and pH problems promptly, you prevent expensive repairs and unplanned downtime. This proactive approach enhances system efficiency and extends equipment lifespan. The long-term financial benefits include significant cost savings and better maintenance planning, giving you peace of mind and optimized operations. Don’t wait—early troubleshooting makes a smart investment in your system’s future.

Conclusion

Did you know that poor pH control and corrosion can increase equipment costs by up to 30% annually? By understanding the hidden costs and implementing proper maintenance and calibration, you can markedly extend your system’s lifespan and efficiency. Address issues early with quality monitoring tools and proactive strategies. Remember, timely troubleshooting isn’t just about saving money—it’s about safeguarding your investment and ensuring reliable operations for years to come.