The hidden costs of softener regeneration often catch you off guard, including high salt and water expenses, equipment wear, and increased energy use. Frequent regeneration can shorten your system’s lifespan and lead to costly repairs, while poor maintenance worsens inefficiency and costs. To save money and extend your system’s life, it’s essential to monitor cycles, optimize settings, and perform regular upkeep. Keep going to discover practical solutions to reduce these hidden expenses effectively.

Key Takeaways

- Frequent regeneration increases salt and water costs, leading to higher utility bills and environmental impact.

- Excessive cycling shortens equipment lifespan through corrosion, resin degradation, and component wear.

- High energy use from unnecessary cycles boosts electricity expenses and system inefficiency.

- Poor maintenance causes mineral buildup and system fouling, raising resource consumption and repair costs.

- Implementing demand-based regeneration and using salt alternatives can significantly reduce hidden expenses.

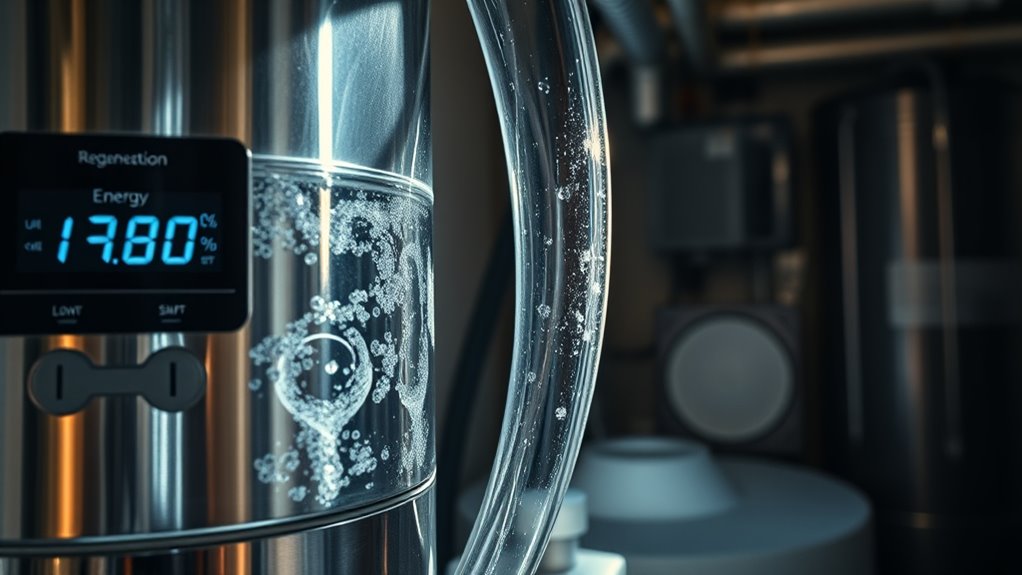

The True Cost of Salt and Water Usage

While softened water may seem like a simple fix, it actually comes with hidden expenses related to salt and water consumption. Every regeneration cycle requires a significant amount of salt, which adds up financially over time. You might not realize that the salt costs can be substantial, especially if your system regenerates frequently. Additionally, water expenses increase because softeners use large volumes of water during regeneration, sometimes wasting more than necessary. These water expenses can inflate your utility bills and contribute to environmental concerns. It’s easy to overlook these costs at first, but they add up quickly. By understanding the true cost of salt and water usage, you can better evaluate the ongoing expenses of maintaining your softener and consider ways to reduce unnecessary regeneration cycles. Efficient Softener Operation can further help minimize these hidden costs.

Impact of Frequent Regeneration on Equipment Longevity

Frequent regeneration cycles can considerably shorten the lifespan of your water softener’s components. When you regenerate too often, the constant exposure accelerates tank corrosion, especially if the tank isn’t properly maintained or made from corrosion-prone materials. Additionally, resin degradation speeds up, reducing the system’s efficiency and requiring early replacement. The resin beads wear out faster, leading to poorer softening performance and increased salt and water usage. Over time, the buildup of mineral deposits and repeated chemical exposure weaken internal parts, causing leaks or failures. If you regenerate unnecessarily, you risk costly repairs or premature replacement of your softener. To extend your equipment’s longevity, monitor your regeneration schedule, avoid excessive cycles, and ensure your system is well-maintained. Regular maintenance and understanding system efficiency can help prevent these issues.

Energy Consumption and Its Hidden Expenses

Every regeneration cycle consumes energy, adding to your household’s overall power usage. This energy powers the ion transfer process, where the softener recharges its resin beads. Over time, repeated cycles can lead to increased electricity costs. Additionally, inefficient softener operation may promote softener scaling, which hampers performance and increases energy demands. To visualize this, consider the table below:

| Cycle Type | Energy Use Impact | Potential Costs |

|---|---|---|

| Regular Regeneration | Consumes power for ion transfer | Higher utility bills |

| Inefficient Timing | More frequent cycles | Increased energy expenses |

| Hard Water Conditions | Accelerates softener scaling | Repairs and replacements |

Reducing unnecessary regeneration saves energy, lowers expenses, and prolongs your equipment’s lifespan.

How Poor Maintenance Can Lead to Increased Expenses

Poor maintenance of your water softener can substantially increase your expenses over time. When you neglect regular upkeep, mineral buildup and resin fouling occur more quickly, forcing the system to work harder. Maintenance neglect often leads to inefficient regeneration cycles, which can cause excessive salt and water use, driving up costs. Additionally, failing to replace filters or inspect the system regularly can result in damage that’s costly to repair or replace. Over time, these small oversights lead to significant cost escalation, as your softener consumes more resources while delivering subpar performance. Ignoring celebrity lifestyle insights may seem harmless but can also contribute to unforeseen expenses related to system modifications or upgrades. By staying on top of maintenance tasks, you prevent unnecessary expenses, extend the lifespan of your system, and keep your overall costs in check. Neglecting maintenance only amplifies hidden costs over time.

Strategies to Minimize Costs and Maximize Efficiency

To keep your water softener running efficiently and save money, adopting proactive maintenance strategies is essential. Regularly monitor your brine disposal process to prevent costly overflows and environmental issues. Using salt alternatives, such as potassium chloride, can reduce salt costs and lessen environmental impact while maintaining soft water quality. Adjust regeneration cycles based on actual water usage instead of sticking to default settings, minimizing unnecessary regeneration and salt consumption. Consider installing a timer or demand-initiated system to optimize regeneration timing. Keep an eye on salt levels and fill the brine tank only when needed. Properly maintaining valves and controls prevents leaks and inefficiencies. Additionally, understanding the optimal angles for pinball machines can improve gameplay performance and extend the lifespan of your equipment. By implementing these strategies, you’ll extend your softener’s lifespan, reduce hidden costs, and maximize overall efficiency.

Frequently Asked Questions

How Does Water Quality Affect Softener Regeneration Costs?

Water quality directly impacts your softener regeneration costs because high water hardness and mineral buildup cause your system to work harder. When minerals like calcium and magnesium are abundant, the softener needs more frequent regeneration, increasing your expenses. To avoid this, you can install pre-treatment systems, use efficient regeneration cycles, and monitor water quality regularly, ensuring your softener operates smoothly and cost-effectively.

Are There Alternative Regeneration Methods That Save Money?

Yes, you can save money with alternative regeneration methods like using salt-free water conditioners or demand-initiated regeneration systems. These options reduce salt and water usage, lowering ongoing costs. Employing cost-saving techniques such as scheduling regeneration during off-peak hours or adjusting regeneration settings based on actual water usage also helps you cut expenses. Explore these methods to make your water softening more affordable without sacrificing quality.

What Are Signs of Inefficient Regeneration Processes?

You’ll notice inefficient regeneration processes if your softener’s regeneration frequency seems too high or too low, leading to hard water issues or salt wastage. Excessive salt usage indicates over-regeneration, while frequent cycles with little benefit suggest under-regeneration. Keep an eye on water hardness levels and monitor salt consumption regularly. Adjust your regeneration schedule accordingly to optimize performance, save money, and prevent hidden costs associated with improper regeneration cycles.

Can Softener Settings Be Optimized to Reduce Costs?

Think of your softener as a finely tuned instrument—adjusting the settings can hit just the right note. By optimizing softener calibration, you conserve resin longevity and slash costs. Fine-tune regeneration cycles based on water usage patterns, and avoid over- or under-regenerating. This proactive approach guarantees your system hums smoothly, extending resin life and trimming unnecessary expenses—making every drop of water count without draining your budget.

How Does Environmental Impact Influence Softener Regeneration Choices?

Environmental impact influences your softener regeneration choices markedly. You should prioritize eco-friendly options that comply with environmental regulations, reducing harmful waste and chemical runoff. Opting for systems with minimal salt or alternative regeneration methods helps lower your ecological footprint. By choosing environmentally conscious softeners, you contribute to sustainability efforts, save on long-term costs, and support a healthier planet. Always consider eco-friendly options to align your water treatment with environmental standards.

Conclusion

Remember, a stitch in time saves nine. By being mindful of your softener’s salt, water, and energy use, and maintaining it properly, you can avoid costly repairs and replacements down the line. Regularly check your system and follow best practices to keep costs low and efficiency high. Don’t wait until problems arise—staying proactive guarantees your softener runs smoothly, saving you money and hassle. After all, prevention is better than cure.