To understand the 7 rules of pH and corrosion, you need to recognize how pH influences material breakdown—acidic environments speed up corrosion while alkaline conditions slow it down. Monitoring pH levels regularly helps you catch early signs of deterioration, and choosing the right materials or coatings can prevent damage. Managing environmental factors and inspections also extend system life. Keep exploring, and you’ll discover key tips to protect your assets more effectively.

Key Takeaways

- Maintaining appropriate pH levels is vital to prevent accelerated corrosion, especially in acidic environments.

- Regular pH testing helps detect shifts that could increase material vulnerability and corrosion risks.

- Different metals respond uniquely to pH changes; selecting suitable materials enhances durability.

- Using corrosion inhibitors and protective coatings can stabilize pH and shield materials from degradation.

- Controlling environmental factors like humidity and chemical exposure supports optimal pH and reduces corrosion.

Understanding Ph Levels and Their Impact

Understanding pH levels is essential because they directly influence how materials corrode and how safe water or solutions are. When you perform pH measurement, you’re determining whether a substance is acidic, neutral, or alkaline, which impacts corrosion rates. Acidic environments tend to accelerate corrosion, while alkaline conditions can slow it down. To protect materials, you might use corrosion inhibitors that modify the environment’s pH or form a protective barrier. Knowing the pH helps you choose the right inhibitors and adjust conditions to prevent damage. Proper pH management is crucial in controlling corrosion processes effectively. Whether you’re maintaining pipelines or ensuring water safety, understanding these pH fundamentals enables you to make informed decisions that extend material lifespan and ensure safety. Accurate pH measurement is your first step toward effective corrosion management.

Recognizing the Role of Corrosion in Material Degradation

Corrosion is a primary factor that causes materials to degrade over time, compromising their strength and functionality. Recognizing its role is vital, especially since environmental pH levels influence corrosion rates. When pH levels are unbalanced, materials become more vulnerable to rust and other forms of deterioration. Proper pH balancing helps maintain ideal conditions, reducing corrosion risks. You can also use corrosion inhibitors to protect surfaces from aggressive elements, slowing down material breakdown. Being aware of how corrosion manifests—such as rust, pitting, or material thinning—helps you identify early signs of degradation. Additionally, understanding the effectiveness of coolers and freezers can help prevent moisture-related corrosion in storage environments. By understanding these signs and controlling environmental factors like pH, you can extend the lifespan of your materials and prevent costly damages. Recognizing corrosion’s role is the first step toward better material management and protection.

How Ph Affects Different Types of Metals and Alloys

The pH level of the environment directly influences how different metals and alloys respond to corrosive conditions. Acidic (low pH) environments accelerate corrosion, especially for metals with low pH resistance. Neutral pH (around 7) usually offers stability, but extreme pH levels cause galvanic reactions that can weaken metals. For example, aluminum corrodes faster in acidic conditions, while stainless steel resists pH fluctuations better. Additionally, understanding the contrast ratio of materials can help in selecting metals that maintain integrity under various lighting and environmental conditions.

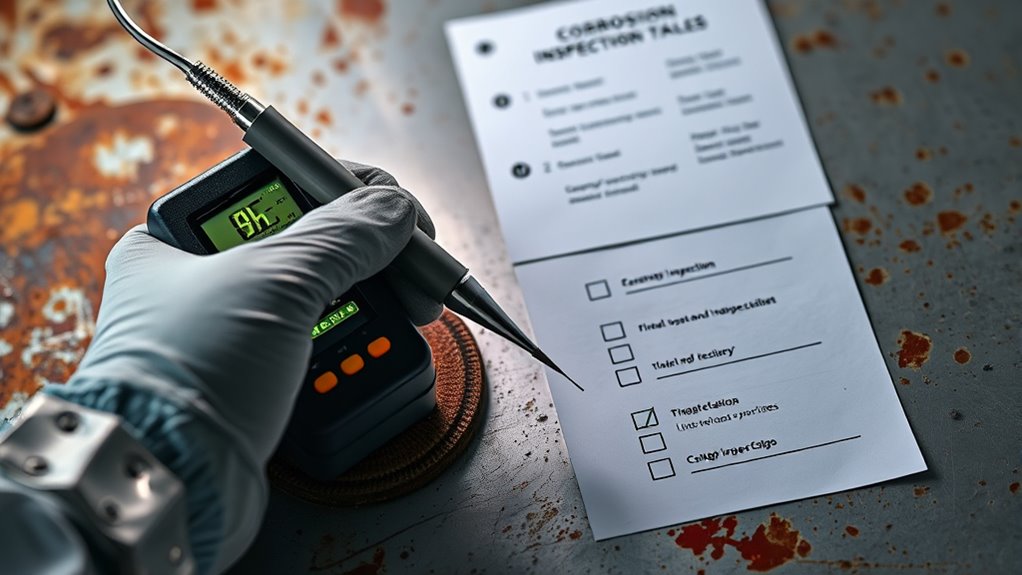

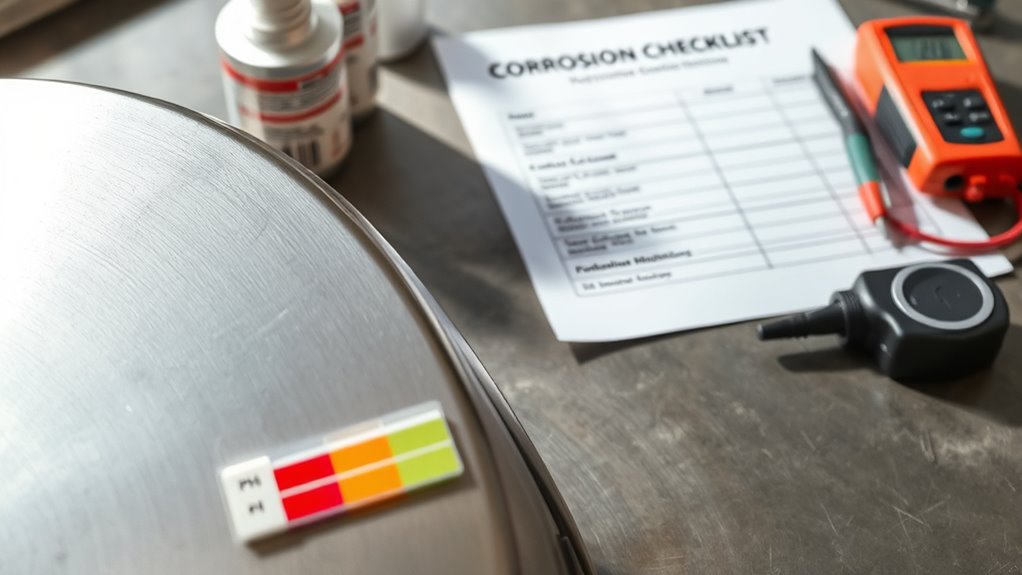

The Importance of Proper Monitoring and Testing

Regularly monitoring and testing your metal structures is essential to prevent costly corrosion damage. Accurate pH measurement helps you detect shifts in acidity or alkalinity that can accelerate corrosion. By consistently checking the pH levels of your environment, you can identify early signs of corrosive conditions and take timely action. Proper testing ensures that your corrosion prevention strategies remain effective and that any potential issues are addressed before significant damage occurs. Don’t rely on guesswork—regular assessments give you a clear picture of your structures’ health. Implementing systematic monitoring routines allows you to maintain ideal pH levels, reducing corrosion risks and extending the lifespan of your equipment. Staying proactive with testing is key to effective corrosion prevention and long-term asset protection. Incorporating water quality assessments into your maintenance routine provides comprehensive insights that can help you optimize your corrosion mitigation efforts.

Preventative Measures to Minimize Corrosion Risks

Implementing preventative measures is vital to minimizing corrosion risks and protecting your metal assets. You should consider coating applications, such as paints, galvanization, or specialized sealants, to create a protective barrier against moisture and corrosive agents. Environmental controls also play an essential role; managing humidity, controlling temperature fluctuations, and reducing exposure to aggressive chemicals can markedly slow corrosion processes. Regular inspections allow you to identify early signs of deterioration, enabling prompt intervention. Combining coating applications with proper environmental controls forms a thorough approach to corrosion prevention. By proactively maintaining these measures, you extend the lifespan of your equipment, reduce maintenance costs, and ensure safety. Staying vigilant and implementing these strategies helps safeguard your assets against the damaging effects of corrosion. Additionally, understanding corrosion basics can help you identify specific vulnerabilities and tailor preventative solutions accordingly.

Selecting the Right Materials for Corrosive Environments

Choosing the right materials for corrosive environments requires careful consideration of their inherent resistance to specific aggressive agents. You need to evaluate material compatibility with the chemicals or pH levels involved, ensuring the material can withstand the environment without degrading. Selecting appropriate materials is essential to prevent premature failure and ensure longevity. Cost considerations also play a essential role; selecting the most resistant material might be ideal, but it must fit your budget. For instance, stainless steel or certain plastics may offer excellent corrosion resistance but come with higher initial costs. Balance durability with affordability to optimize long-term performance. Keep in mind that a material’s compatibility with your environment directly impacts maintenance needs and longevity. Making informed choices now helps prevent costly repairs and system failures down the line.

Maintenance and Inspection Strategies to Extend System Life

Effective maintenance and inspection are crucial for extending the life of your systems, especially in corrosive environments. Regularly monitor pH levels to guarantee proper pH adjustment, preventing conditions that accelerate corrosion. Incorporate corrosion inhibitors into your maintenance routine; these chemicals create a protective barrier, reducing metal degradation. Schedule routine inspections to identify early signs of corrosion or pH imbalance, such as leaks, discoloration, or buildup. Use non-destructive testing methods to assess material integrity without causing additional damage. Keep detailed records of pH adjustments, inhibitor applications, and inspection results to track trends over time. Promptly address issues discovered during inspections, adjusting pH and reapplying inhibitors as necessary. AI-driven solutions are increasingly being integrated into maintenance strategies to optimize system performance. Consistent, proactive maintenance greatly prolongs system life and minimizes costly failures.

Frequently Asked Questions

How Does Ph Fluctuation Influence Long-Term Corrosion Rates?

pH fluctuation impacts long-term corrosion rates by disrupting pH stability, which can accelerate or slow corrosion depending on the environment. When pH levels shift, corrosion prediction becomes more complex, as unpredictable pH changes can cause localized damage or uniform corrosion. You need to monitor pH regularly to anticipate these effects, ensuring better maintenance and prevention strategies. Stable pH levels help control corrosion, but fluctuations increase the risk of long-term damage.

Can Ph Levels Be Adjusted Safely in Industrial Systems?

Think of adjusting pH levels like tuning a musical instrument—you want precision for harmony. You can safely modify pH levels in industrial systems through controlled chemical balancing and process optimization, using proper dosing and monitoring. Regular testing guarantees stability, preventing corrosion or damage. Implementing automated pH control systems also helps maintain safe, consistent conditions, much like a skilled conductor keeps an orchestra in sync.

What Are the Common Signs of Corrosion Damage in Early Stages?

You can spot early corrosion damage through signs like discoloration, surface roughness, or paint bubbling. Corrosion detection often reveals small pits or blistering that aren’t yet structural issues but serve as early warnings. Regular inspections help you catch corrosion early, preventing costly repairs. Pay close attention to these signs, and act quickly to maintain system integrity, especially in environments prone to moisture or chemical exposure.

How Do Environmental Factors Like Temperature Affect Ph and Corrosion?

Environmental factors like temperature substantially affect pH stability and corrosion rates. Higher temperatures can accelerate corrosion by increasing chemical reaction speeds, making materials more vulnerable. You should conduct regular environmental monitoring to track temperature changes and pH fluctuations, helping you identify potential risks early. By understanding these factors, you can implement proper controls to minimize corrosion damage and maintain the integrity of your materials and structures.

Are There Eco-Friendly Corrosion Inhibitors for Different Ph Ranges?

Think of eco-friendly inhibitors as gentle guardians that shield your materials without disturbing nature’s harmony. Yes, they exist for different pH ranges, offering pH stability and corrosion protection. These environmentally safe options, often derived from plant extracts or organic compounds, actively prevent rust while keeping ecosystems safe. Using eco-friendly inhibitors is like planting a protective shield that preserves both your assets and the planet, ensuring sustainable corrosion control.

Conclusion

By mastering the myths of pH and corrosion, you can confidently combat costly corrosion and capitalize on consistent system safety. Monitoring, maintaining, and materializing your methods guarantees longevity and limits loss. Stay vigilant, verify variables, and venture into vigilant, valuable vigilance. With these seven simple steps, you’ll safeguard your systems, strengthen your strategies, and secure a sustainable, corrosion-free future—because prevention, preparedness, and proactive practices pave the path to perfection.