If you’re looking for the best low pressure drop shutoff valves for 2025, I recommend considering options like stainless steel ball valves, brass shut-off valves, auto shut-off parts for reverse osmosis systems, and quick-connect models. These valves are designed for seamless flow, high durability, and compatibility with various systems like water and gas lines. If you keep going, you’ll find detailed insights on each valve’s features and how to choose the right one for your needs.

Key Takeaways

- Full port design in valves reduces pressure drop, ensuring seamless flow for various applications.

- Durable materials like brass, stainless steel, and corrosion-resistant plastics enhance longevity and performance.

- Compatibility with multiple pipe sizes and fittings simplifies installation and system integration.

- High-pressure handling capabilities up to 7250 PSI support demanding hydraulic and industrial systems.

- Auto shut-off features improve safety and efficiency by quickly responding to pressure changes.

Beduan Mini Ball Valve, 316 Stainless Steel NPT Thread Shut-Off Valve

If you’re looking for a reliable shut-off valve that combines durability with ease of operation, the Beduan Mini Ball Valve is an excellent choice. Made from sturdy 316 stainless steel, it resists corrosion and handles demanding environments well. Its 1/2-inch NPT threaded design makes installation straightforward. The double-seal system allows bidirectional flow, adding versatility. The heavy-duty aluminum alloy handle ensures durability and smooth operation with a simple quarter-turn to open or close. Whether used as a shut-off or water-saving adjustable valve, its compact design fits easily into tight spaces, making it ideal for various piping setups.

Best For: DIY enthusiasts and professionals needing a durable, corrosion-resistant shut-off valve for tight piping spaces and demanding environments.

Pros:

- Made from durable 316 stainless steel for excellent corrosion resistance

- Easy to operate with a quarter-turn on/off handle for quick control

- Double-seal system allows bidirectional flow and enhances sealing reliability

Cons:

- May be more expensive than plastic or lower-grade metal valves

- Requires compatible NPT threading for proper installation

- The compact size might limit flow capacity in larger piping systems

Brass Mini Shut Off Ball Barb Valve (2 pcs with Clamps)

The Brass Mini Shut Off Ball Barb Valve (2 pcs with Clamps) is an excellent choice for those needing reliable, compact shutoff solutions in water, fuel, or gas lines. Made of heavy-duty brass, it features a 3/8-inch hose barb connection suitable for outdoor irrigation, oil, or gas systems. The straight inlet design allows easy installation behind walls or underground without access panels. Each package includes two valves with clamps, ensuring secure connections. With a temperature range from -39℉ to 380℉ and a working pressure of 400 psi, these valves provide durable, seamless flow control for residential or commercial applications.

Best For: DIY homeowners, plumbers, and contractors seeking reliable, compact shutoff valves for water, gas, or fuel lines in residential or outdoor applications.

Pros:

- Made of heavy-duty brass for durability and long-lasting performance

- Easy to install with 3/8-inch hose barb connections and included clamps

- Suitable for underground and behind-wall installations without access panels

Cons:

- Limited to 3/8-inch hose size, not compatible with larger piping

- Operating temperature range may be restrictive for certain extreme environments

- May require additional tools or fittings for specific system configurations

APEC Water Systems Auto Shut Off Valve Replacement Part (ASO)

The APEC Water Systems Auto Shut Off Valve Replacement Part (ASO) stands out as an ideal choice for homeowners seeking a reliable, easy-to-install solution to prevent water waste in their reverse osmosis systems. Designed for models like RO-45, RO-90, and others, it features quick connect fittings and a lightweight, NSF-certified plastic body. Installation is straightforward, typically completed in minutes without tools, by connecting the inlet and outlet lines correctly. Regular replacement ensures peak performance, preventing leaks and system failures. Many users appreciate its affordability and ease of use, making it a practical choice for maintaining efficient, leak-free RO systems.

Best For: homeowners with reverse osmosis systems looking for an easy-to-install, reliable shutoff valve to prevent water waste and system leaks.

Pros:

- Simple, tool-less installation suitable for quick setup

- Compatible with multiple RO system models, including popular brands

- NSF-certified plastic body ensures safety and durability

Cons:

- Some units may arrive defective or have shorter lifespan depending on the brand

- Installation instructions can be unclear, requiring user experience or additional research

- Build quality varies, and improper handling during maintenance can cause damage

2 Pack Brass Mini Ball Valve 1/2 NPT Female x Male Thread Shut-Off Valve

For those seeking reliable flow control in low-pressure applications, the Pack Brass Mini Ball Valve 1/2 NPT Female x Male Thread stands out as an economical and versatile choice. Made from durable brass and aluminum, it features a simple quarter-turn operation and a double-seal system that allows flow in both directions. Its compact size and easy installation make it ideal for air, gas, liquid, and steam setups like air tanks or low point drains. While not suitable for permanent installations due to thread and material limitations, it offers good performance for temporary or low-pressure needs, with customer reviews highlighting its affordability and ease of use.

Best For: DIY enthusiasts and professionals needing cost-effective, temporary flow control solutions for air, gas, liquid, or steam low-pressure applications.

Pros:

- Easy quarter-turn operation for quick shut-off and flow control

- Compact and lightweight design for space-saving installation

- Made from durable brass and aluminum, suitable for temporary use

Cons:

- Not recommended for permanent installations due to thread and material limitations

- Requires washers or Teflon tape for proper sealing to prevent leaks

- Some users reported durability issues or leaks when not installed correctly

Eastman Multi-Turn Angle Stop Valve

If you’re seeking a reliable valve that offers precise flow control and easy maintenance, the Eastman Multi-Turn Angle Stop Valve stands out as an excellent choice. It controls water to household fixtures without affecting the entire home, making repairs straightforward. Constructed from solid brass with a chrome finish, it resists corrosion and lasts for years. With leakproof Teflon seats and a durable Celcon stem, it ensures a watertight seal. Supporting up to 125 PSI, it’s compatible with various fixtures like faucets and toilets. Many users praise its durability, smooth operation, and simple installation, making it a trusted option for long-term flow management.

Best For: homeowners and DIY enthusiasts seeking a durable, easy-to-maintain angle stop valve for reliable fixture shutoff and long-term plumbing solutions.

Pros:

- Constructed from solid brass with a chrome finish for corrosion resistance and durability

- Leakproof operation with Teflon seats and a high-performance Celcon stem ensures a watertight seal

- Supports up to 125 PSI and compatible with various household fixtures for versatile use

Cons:

- Multi-turn operation may be less convenient than quarter-turn valves for quick shutoff

- Slightly larger size compared to some quarter-turn valves might require more space

- Installation may require compression fittings, which can be more complex for beginners

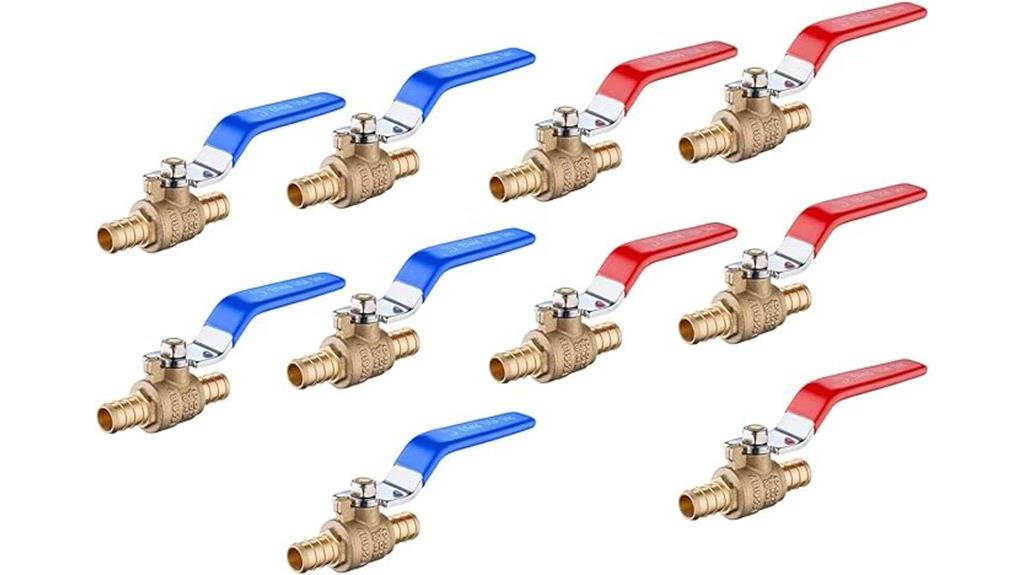

Pack of 10) EFIELD 1/2 Inch Pex Crimp Brass Full Port Shut-off Ball Valve

Ideal for bulk plumbing projects or repairs, the Pack of 10 EFIELD 1/2 Inch PEX Crimp Brass Full Port Shut-off Ball Valves offers reliable, easy-to-install shutoff points that support seamless flow control. Made from corrosion-resistant DZR brass, these valves are certified by ASTM F1807, NSF, and UPC standards, suitable for hot and cold water. Their full port design minimizes flow restriction, and they work with various PEX fittings, supporting pressures up to 400 PSI. Installation is simple and solder-free, allowing rotation after crimping for perfect alignment. With high customer ratings, they’re a cost-effective, durable choice for widespread plumbing applications.

Best For: DIY homeowners and professional plumbers seeking bulk, reliable PEX shut-off valves for water system installations and repairs.

Pros:

- Easy solder-free installation with crimp connections

- Supports high pressure up to 400 PSI for durable performance

- Compatible with multiple PEX fittings and tubing types

Cons:

- Not compatible with Shark PEX systems

- Slight ridges inside the valve body may affect flow slightly

- Requires proper crimping tools and technique for optimal seal

Eastman 1/2 Inch Compression Ball Valve, Brass Plumbing Fitting

The Eastman 1/2 Inch Compression Ball Valve stands out for those seeking a durable, easy-to-install solution for seamless flow control in plumbing systems. Made from heavy-duty brass, it features a full port design that minimizes pressure drops and maximizes flow. The Teflon seal handles high temperatures and pressures up to 600 PSI, ensuring reliable performance. Its vinyl-coated steel handle allows for smooth operation, while the compression connections simplify installation without soldering. Certified by NSF, CSA, and UPC, this valve is suitable for potable water. At just 8.1 ounces, it’s compact and practical, making it an excellent choice for various plumbing applications.

Best For: homeowners, plumbers, and DIY enthusiasts seeking a durable, easy-to-install valve for reliable flow control in potable water systems.

Pros:

- Heavy-duty brass construction ensures long-lasting durability

- Full port design maximizes flow and minimizes pressure drops

- Easy installation with compression fittings and no soldering required

Cons:

- Some users have reported initial missing parts like lock nuts or crimp rings

- Slightly larger size may require space considerations in tight installations

- Not suitable for applications exceeding 600 PSI or high-temperature steam beyond rated limits

NKAIKE Hydraulic High Pressure Shut-Off Ball Valve (3/8 Inch NPT, 7250 PSI)

For high-pressure hydraulic systems demanding maximum durability and leak-proof performance, the NKAIKE Hydraulic High Pressure Shut-Off Ball Valve stands out. Made of carbon steel with zinc plating, it resists corrosion and withstands up to 7250 PSI. Its 3/8 NPT threads ensure a secure, tight fit, while the high-quality NBR seal prevents leaks even under extreme pressure. Designed specifically for hydraulic and water applications, this valve offers reliable shut-off control without sacrificing flow efficiency. Its robust construction and precise sealing make it an excellent choice for demanding environments where durability and safety are paramount.

Best For: professionals and technicians working with high-pressure hydraulic or water systems requiring reliable, corrosion-resistant shut-off solutions.

Pros:

- Capable of handling extremely high pressures up to 7250 PSI for demanding applications

- Made of durable carbon steel with zinc plating for excellent corrosion resistance

- Provides a secure, leak-proof seal with high-quality NBR material, ensuring safety and efficiency

Cons:

- May require specialized tools or expertise for installation and maintenance

- Limited to 3/8 inch NPT thread size, which may not fit all system configurations

- Not suitable for applications involving aggressive chemicals unless specified

Watts 1 1/4 in Reduced Pressure Zone Assembly, Quarter Turn Shutoff Valves

If you’re seeking reliable flow control with minimal pressure loss, Watts’ 1 1/4 inch Reduced Pressure Zone Assembly with quarter turn shutoff valves stands out. Made from durable lead-free bronze, it features large body passages for low pressure drops. The quarter turn, full port resilient seated ball valves allow quick, smooth shutoffs. Its modular check construction makes maintenance easy, while captured springs ensure safe servicing. The single access cover simplifies inspections and repairs. Overall, this assembly provides seamless flow regulation and dependable shutoff performance, making it an excellent choice for applications demanding low pressure drop and straightforward maintenance.

Best For: plumbing professionals and facilities managers seeking durable, easy-to-maintain flow control solutions with low pressure drops in various water systems.

Pros:

- Made from lead-free bronze for long-lasting durability

- Large body passages enable low pressure drop for efficient flow

- Modular check construction and captured springs simplify maintenance

Cons:

- May require specialized tools for servicing due to modular components

- The size (1 1/4 inch) may not suit smaller or more compact applications

- Specific product details may need to be requested, potentially delaying procurement

EFIELD Brass Ball Valve with Drop-ear, 3/4 Inch PEX Full Port Shut-off

When seeking a reliable valve that combines durability with easy installation, the EFIELD Brass Ball Valve with Drop-ear stands out. Made from sturdy brass with a stainless steel exterior finish, it’s compatible with all PEX tubing types and brands. Its full port design ensures unobstructed flow, making it ideal for main shut-offs, fixtures, and drains. The drop-ear mounting system simplifies installation, while the manual operation requires no batteries. Rated highly with 4.8 stars from 135 reviews, users praise its durability, leak resistance, and value. Certified under ASTM F1807 and NSF/ANSI 61, this valve offers quality, safety, and versatility for residential and outdoor plumbing needs.

Best For: Homeowners and DIY plumbers seeking a durable, easy-to-install valve for residential or outdoor plumbing applications.

Pros:

- Made from sturdy brass with a stainless steel exterior for long-lasting durability

- Compatible with all PEX tubing types and brands, including clamp and crimp systems

- Full port design provides unobstructed water flow and reliable shut-off

Cons:

- Some lower-cost Chinese-made options may lack long-term exposure resistance

- No additional accessories or fittings included with the valve

- Requires manual operation, which might be less convenient for automated systems

Merrill MFG Lead-Free Pressure Relief Valve

The Merrill MFG Lead-Free Pressure Relief Valve stands out as an ideal choice for those seeking a reliable, environmentally safe solution for cold water systems. Made from lead-free brass with stainless steel control springs, it’s certified by IAMPO for safety and durability. Designed for pressures up to 100 PSI, it features a 1/2 inch male NPT inlet and 1/2 inch female FPT outlet. Its compact size and corrosion-resistant stainless steel exterior make it easy to install and long-lasting. Customers praise its effective pressure regulation and value, though some note minor issues like packaging or residual tape. Overall, it’s a solid, eco-friendly option for safeguarding cold water systems.

Best For: homeowners or professionals seeking a durable, eco-friendly pressure relief valve for cold water systems up to 100 PSI.

Pros:

- Made from lead-free brass with stainless steel springs for durability and environmental safety

- Certified by IAMPO, ensuring compliance with safety and performance standards

- Compact, corrosion-resistant design simplifies installation and enhances longevity

Cons:

- Some customers received open packages or experienced residual tape on threads, indicating possible mishandling

- Limited to cold water applications, not suitable for water heater systems

- Minor issues with packaging or internal corrosion reported by a few users

Garosa RO Low Pressure Switch 1/4 DC 24V for Water Reverse Osmosis System

Garosa’s RO Low Pressure Switch 1/4 DC 24V stands out as an excellent choice for water reverse osmosis systems that demand reliable pressure-based pump control. Designed specifically for applications like water purifiers and pure water machines, it automatically shuts off the pump when water pressure drops below 0.01 MPa, protecting your equipment. Its simple installation and compact size make it easy to integrate. Made from durable plastic, it responds quickly to pressure changes, ensuring seamless flow and system safety. With a 5-star customer rating and a focus on efficiency, this switch is a dependable component for maintaining ideal reverse osmosis performance.

Best For: those seeking a reliable, pressure-sensitive switch for water reverse osmosis systems, water purifiers, and similar equipment requiring precise pump control.

Pros:

- Simple installation and compact design for easy integration

- Responds quickly to pressure changes, ensuring system safety

- Durable plastic construction with a 24V DC operation for reliable performance

Cons:

- Limited to applications requiring DC24V operation only

- May not be suitable for systems with pressures significantly above or below 0.01 MPa

- Small size may require careful handling during installation

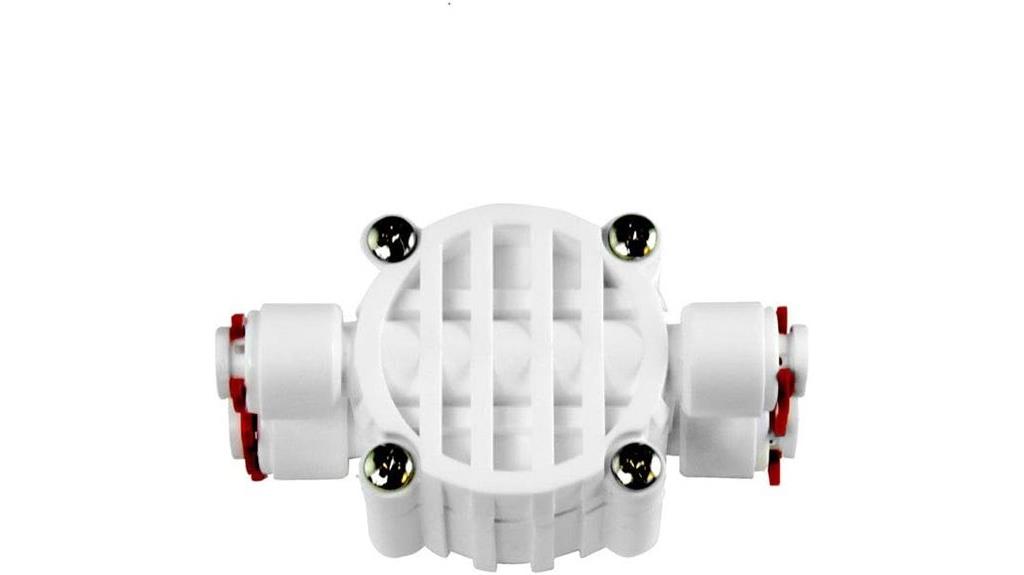

Auto Shut Off Valve for RO Water System

If you’re looking to optimize your reverse osmosis water system, an auto shut off valve like Max Water’s Model 105112 is vital. It automatically stops water flow once the tank reaches about two-thirds capacity, saving over 1,000 gallons monthly and extending membrane life. The quick-connect fittings make installation straightforward, and the device handles water pressures up to 60 psi. However, proper setup is essential, as higher pressures can cause leaks or surges. While most users appreciate the water-saving benefits, some report leaks or quality issues. Overall, this valve helps improve efficiency and protect your system when installed correctly.

Best For: homeowners and DIY enthusiasts seeking an easy-to-install solution to conserve water and extend the lifespan of their reverse osmosis system.

Pros:

- Easy quick-connect fittings for straightforward installation

- Saves over 1,000 gallons of water each month, improving efficiency

- Helps prolong membrane life by preventing overfilling

Cons:

- Some users report leaks or defective parts upon receipt

- Construction may be thinner plastic, affecting durability

- Proper pressure regulation is necessary to prevent surges and leaks

Factors to Consider When Choosing a Low Pressure Drop Shutoff Valve

When selecting a low pressure drop shutoff valve, I focus on key factors like flow rate efficiency and material compatibility to guarantee reliable performance. I also consider the pressure tolerance range and seal integrity to prevent leaks and handle system demands. finally, I look for installation simplicity to save time and reduce potential errors during setup.

Flow Rate Efficiency

Achieving high flow rate efficiency in a low pressure drop shutoff valve is vital for maintaining ideal system performance. When flow efficiency is high, pressure drops are minimized, which helps keep energy consumption low and guarantees smooth operation. Choosing a valve with a full port design can considerably reduce flow resistance and pressure loss during use. The internal diameter and seating mechanism are also essential; larger diameters typically allow better flow and lower pressure drops. Additionally, material and surface finish play important roles—they influence flow smoothness by preventing turbulence. Proper sizing relative to your system’s flow requirements is important, too. Oversized or undersized valves can cause unnecessary pressure drops, hampering efficiency. Focusing on these factors guarantees a valve that delivers seamless flow control with minimal energy waste.

Material Compatibility

Selecting the right material for your low pressure drop shutoff valve is crucial to guarantee long-lasting performance and safety. You need to confirm the valve material is compatible with your fluid, whether it’s brass, stainless steel, or plastic, to prevent corrosion or degradation over time. The sealing components, like Teflon or NBR seals, should resist the chemical properties of your fluid, avoiding leaks and failures. Check that the valve body material meets industry standards such as NSF or ASTM certifications, ensuring quality and safety. Also, verify that the connection types and sizes match your existing piping or tubing system for a proper fit. Finally, consider the operating temperature and pressure ratings of the valve material to ensure durability under your system’s specific conditions.

Pressure Tolerance Range

Understanding the pressure tolerance range of a low pressure drop shutoff valve is essential to make certain it functions reliably within your system. This range indicates the minimum and maximum pressures the valve can handle without malfunctioning or leaking, which can vary from 0 psi to several thousand psi depending on the design. Choosing a valve with an appropriate pressure tolerance ensures it maintains effective shutoff performance, especially in systems with fluctuating or high-pressure conditions. If the operating pressure exceeds the valve’s limits, it risks damage, leaks, or complete failure, jeopardizing safety and efficiency. By understanding this range, you can match the valve precisely to your application’s pressure needs, avoiding issues caused by under- or over-specification.

Seal Integrity Quality

The seal integrity of a low pressure drop shutoff valve is vital because it guarantees a leak-proof connection that prevents fluid loss and protects your system from damage. High-quality sealing materials like Teflon or NBR are essential for reliable, long-lasting seals that perform well under different pressures and temperatures. Well-designed seals should accommodate bidirectional flow and resist wear, deformation, and chemical degradation over time. Maintaining seal integrity reduces leaks, pressure drops, and system inefficiencies, ensuring optimal flow control. Regular inspection and maintenance are crucial, especially in systems with frequent operation or exposure to aggressive media. Prioritizing seal quality helps you achieve consistent performance, minimizes downtime, and extends the lifespan of your valve, making it a critical factor in your selection process.

Installation Simplicity

Choosing a low pressure drop shutoff valve that’s easy to install can save you time and effort. Look for valves with a streamlined internal design, like a full port or bore, to reduce flow resistance and simplify installation. Features such as quick-connect fittings or straightforward threading minimize the need for extra tools and speed up the process. Clear, user-friendly instructions and minimal assembly steps help guarantee correct installation without frustration. Compatibility with your existing piping and fittings prevents the need for adapters or modifications that could complicate installation or increase pressure drop. Additionally, a design that allows easy access for maintenance or adjustments without dismantling the whole system makes ongoing operation smoother. These factors collectively make installation quicker, easier, and more reliable.

Durability and Longevity

Durability and longevity are essential when selecting a low pressure drop shutoff valve, as they guarantee reliable performance over time. I look for valves made from corrosion-resistant materials like brass, stainless steel, or high-quality plastics, which can withstand harsh conditions. The valve’s ability to resist wear from frequent operation, indicated by a high cycle count rating, is also fundamental. Proper sealing components, such as Teflon or rubber seals, prevent leaks and reduce internal corrosion, extending the valve’s lifespan. Heavy-duty handles and sturdy internal parts help prevent mechanical failure during repeated use. Additionally, regular maintenance and adhering to recommended operating pressures are necessary for maximizing durability and ensuring the valve performs reliably throughout its service life.

Size and Space

Selecting the right size and space for a low pressure drop shutoff valve guarantees smooth integration into your system. I recommend matching the valve size to your pipe diameter, typically 1/2 inch or 3/4 inch, for proper flow and fitting. Compact, low-profile valves are perfect for tight spaces, making installation easier in confined areas. It’s important to consider the valve’s overall dimensions—length, width, and height—to avoid obstructions and simplify maintenance. If space is limited, inline or quarter-turn valves can minimize footprint while still providing easy access. Additionally, ensure the valve’s mounting and connection types align with your existing piping layout. Proper sizing and spatial planning ensure seamless operation and reduce installation challenges.

Cost-effectiveness

When evaluating low pressure drop shutoff valves, it’s important to take into account their overall cost-effectiveness, which goes beyond just the initial purchase price. A good valve balances upfront costs with long-term savings from reduced energy and water use, thanks to minimal pressure loss. Choosing a valve with high flow efficiency can lower energy consumption and extend the lifespan of pumps and other components, saving repair costs. Valves made from durable materials with reliable seals decrease the likelihood of leaks and failures, preventing costly repairs or downtime. Keep in mind that total cost-effectiveness includes installation, maintenance, and operational savings over the valve’s service life. Investing wisely ensures better performance and lower expenses down the line.

Frequently Asked Questions

How Do Low Pressure Drop Valves Impact Overall System Efficiency?

Low pressure drop valves considerably boost system efficiency by reducing energy consumption and minimizing pressure losses. When I use these valves, I notice smoother flow and less strain on pumps and other components. This means my system operates more reliably, with less maintenance and downtime. Overall, they help me save costs and improve performance, making them a smart choice for seamless flow control in any setup.

Are There Specific Materials Best Suited for Low Pressure Applications?

I’ve found that materials like brass, stainless steel, and certain plastics are ideal for low-pressure applications. Brass offers durability and corrosion resistance, making it great for water systems. Stainless steel provides strength and longevity, perfect for demanding environments. High-quality plastics like PVC and PTFE are lightweight and resistant to chemicals, making them suitable for specific low-pressure uses. Choosing the right material depends on your system’s needs and operating conditions.

What Maintenance Practices Ensure Longevity of Low Pressure Shutoff Valves?

I recommend regularly inspecting your low pressure shutoff valves for leaks, debris, or corrosion. Keep the valve clean and make certain moving parts are lubricated properly. It’s also essential to operate the valve periodically to prevent sticking and replace seals or worn parts as needed. Following these practices helps prevent failures, extends your valve’s lifespan, and ensures seamless flow control over time.

How Do Temperature Variations Affect Valve Performance?

When temperature swings occur, I notice they’re like ripples on a pond—affecting the smooth flow of my valve’s performance. Extreme heat can cause materials to expand, leading to leaks or sluggish operation, while cold can make parts contract, risking seizing or sticking. To keep things running smoothly, I guarantee proper insulation and select valves designed for specific temperature ranges, preventing these subtle yet impactful shifts.

Can These Valves Be Customized for Unique System Requirements?

Yes, these valves can definitely be customized to meet your system’s unique needs. I’ve worked with manufacturers who offer tailored options like specific materials, sizes, and actuator types. Customization guarantees peak performance and compatibility with your setup. If you have particular requirements, I recommend discussing them directly with suppliers—they often provide solutions that perfectly fit your application, ensuring seamless flow control and efficient operation.

Conclusion

So, next time you’re stuck choosing a shutoff valve, remember: don’t settle for a clunky, sluggish gatekeeper that makes your water flow resemble molasses. Opt for a low pressure drop valve, and watch your system run smoother than a well-oiled roller coaster. Because honestly, nobody wants their water flow to resemble a slow-motion soap opera. Choose wisely, and let your plumbing flow like a champion—fast, efficient, and drama-free.