If you’re looking for the 15 best flex connectors in 2025, I’ve got you covered. I recommend options like the RACO 2283B5 screw-in connectors, ProConnex squeeze fittings, and UL-listed liquid-tight PVC options, all known for their durability, ease of installation, and compatibility with various conduit types. Whether for indoor or outdoor use, these connectors ensure secure, reliable connections. Keep exploring, and you’ll discover all the key features to choose the best fit for your project.

Key Takeaways

- The top flex connectors in 2025 offer durable materials like zinc die-cast and stainless steel for long-lasting, corrosion-resistant connections.

- They come in various sizes, primarily 1/2″, 3/4″, and 1″, compatible with FMC, RWFMC, and flexible metallic conduits.

- Easy installation features include tri-combo screws, push-in designs, and 90-degree bends for secure and efficient setup.

- Certifications such as UL and CSA ensure these connectors meet safety standards for indoor and outdoor applications.

- They provide versatile options for sealing, grounding, and adapting to different conduit and enclosure types for seamless wiring.

RACO 2283B5 Connector, Screw-in, 3/4-Inch Trade Size, Flex, Zinc, 5-Pack

If you’re looking for a reliable connector for flexible metal conduit, the RACO 2283B5 is an excellent choice, especially because it’s designed for professional-grade electrical installations. This screw-in connector fits 3/4-inch trade-size flexible conduit and comes in a convenient 5-pack. Made from die cast zinc, it offers excellent mechanical protection and corrosion resistance, ensuring long-lasting durability. Its gray zinc finish enhances durability in harsh environments. Certified by UL and CSA, it meets safety standards and guarantees reliable performance. Whether you’re installing or repairing, this connector provides a secure, corrosion-resistant connection, making your electrical work safer and more efficient.

Best For: Professional electricians and contractors seeking durable, corrosion-resistant connectors for flexible metal conduit installations.

Pros:

- Made from die cast zinc for excellent mechanical protection and corrosion resistance

- Fits 3/4-inch trade-size flexible conduit securely

- UL and CSA certified for safety and compliance

Cons:

- Only compatible with 3/4-inch flexible metal conduit

- May require specific tools for installation due to screw-in design

- Available only in a 5-pack, which may be more than needed for small projects

ProConnex 1/2 Flex Squeeze Connector Conduit Fitting, 25-pack

The ProConnex 1/2 Flex Squeeze Connector Conduit Fitting, available in a convenient 25-pack, is an excellent choice for electricians seeking reliable and easy-to-install connectors for terminating AC, MC, or FMC/RWFMC cables. Made from zinc die-cast, it features a tri-combo screw for a secure connection and fits 1/2-inch knockout boxes or enclosures. Suitable for aluminum or steel cables, including 6/3 AC and MC, it’s rated for 600 volts and tested to CSA and UL standards. Users appreciate its durability and straightforward installation, though some note fitment issues with specific cable types. Overall, it’s a solid, cost-effective option for professional wiring needs.

Best For: Professional electricians and wiring specialists seeking reliable, easy-to-install connectors for terminating 1/2-inch conduit and cable systems in dry locations.

Pros:

- Durable zinc die-cast construction with secure tri-combo screw design

- Compatible with various cable types including aluminum and steel, suitable for 6/3 AC and MC cables

- Meets CSA and UL standards, rated for 600 volts, ensuring safety and reliability

Cons:

- May have fitment issues with certain cable types like 12/2 MC cable

- Not compatible with 1/2-inch MC 12/2 electrical cable

- Limited to dry location applications, not suitable for wet or damp environments

36 Pack Liquid Tight Conduit Connectors (PVC, Straight & 180°, UL Listed)

For those seeking reliable, easy-to-install liquid tight conduit connections, the Pack Liquid Tight Conduit Connectors (PVC, Straight & 180°, UL Listed) stand out as an excellent choice. This 36-pack includes 1/2-inch fittings made of durable PVC, perfect for long-term use in various electrical and outdoor applications. With a quick-connect design, you can install without tools—simply push the conduit onto the ferrule and tighten the sealing nut. Suitable for AC equipment, marine systems, and outdoor lighting, these UL-listed connectors ensure a secure, sealed fit. Customers praise their quality, affordability, and ease of use, making them a top choice for professionals and DIYers alike.

Best For: DIY enthusiasts and professionals seeking reliable, easy-to-install liquid tight conduit connections for electrical and outdoor applications.

Pros:

- High-quality PVC construction ensures durability and long-term use

- Tool-free, quick-connect design simplifies installation process

- UL listed and highly rated for sealing performance and safety

Cons:

- Limited to 1/2-inch conduit sizes only

- May require additional fittings for complex wiring setups

- Some users might prefer metal connectors for specific environments

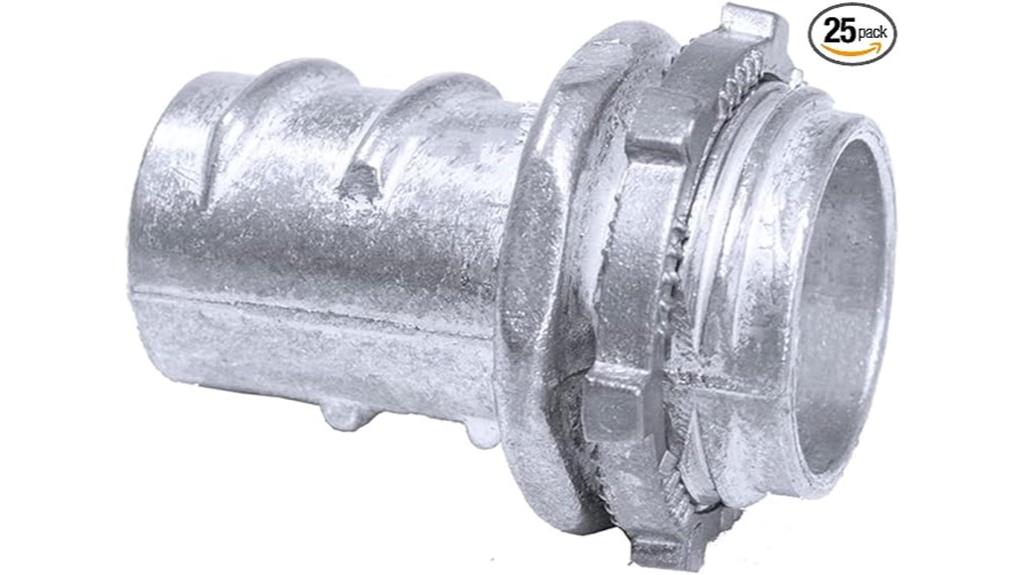

ProConnex 3/4 Flex Screw-In Connector Conduit Fitting, 25-pack

ProConnex 3/4 Flex Screw-In Connector Conduit Fitting stands out as an ideal choice for electrical professionals seeking durable and reliable terminations for Flexible Metal Conduit (FMC) in dry environments. This zinc die-cast connector screws directly into a 3/4-inch knockout, ensuring a tight, secure fit. It’s suitable for steel FMC, with a zinc exterior finish that resists corrosion. The union connector design allows easy installation, and its NPT threads provide a dependable, long-lasting connection. Sold in a convenient 25-pack, it’s perfect for bulk projects. Rated highly for quality and ease of use, it’s a dependable solution for secure conduit terminations in dry settings.

Best For: electrical professionals needing durable, secure, and corrosion-resistant terminations for Flexible Metal Conduit (FMC) in dry indoor environments.

Pros:

- Easy to install with screw-in design and NPT threading for secure connections

- Made from durable zinc die-cast and alloy steel, resistant to corrosion

- Sold in a convenient bulk pack of 25 pieces, ideal for large projects

Cons:

- May have packaging or quantity discrepancies in bulk orders as noted by some users

- Designed specifically for dry locations, limiting use in wet or damp environments

- No additional components or features beyond basic screw-in connector

24 Pack Heavy Duty Stainless Steel Corrugated Water Connectors with Washers

If you’re seeking a durable, high-quality water connector for heavy-duty applications, this 24-pack of stainless steel corrugated water connectors with washers is an excellent choice. Designed for easy installation, these 24-inch flex connectors fit 1-inch CPVC and threaded connections like A.O. Smith models. Made from sturdy stainless steel with a corrugated design, they offer flexibility, kink resistance, and high pressure tolerance up to 125psi. The heavy-duty washers guarantee a secure seal, reducing leaks. While the rigidity requires careful handling, proper installation without over-tightening assures a reliable, leak-free connection, ideal for water softeners and water heaters in residential and commercial settings.

Best For: homeowners and professionals seeking durable, high-pressure water connectors for installing or replacing water softeners and water heaters in residential or commercial settings.

Pros:

- Made from heavy-duty stainless steel for durability and corrosion resistance

- Corrugated design provides flexibility and kink-free installation

- Compatible with 1-inch CPVC and threaded connections like A.O. Smith models

Cons:

- Less flexible than hoses due to stiffness, requiring careful handling during installation

- Slightly higher cost compared to some rubber or plastic alternatives

- Proper washer seating and avoiding over-tightening are critical to prevent leaks

Sigma Engineered Solutions ProConnex Fitting 3/4-Inch Conduit Connector (Gray, 1-Pack)

The Sigma Engineered Solutions ProConnex Fitting 3/4-Inch Conduit Connector stands out as an excellent choice for professionals seeking a durable, easy-to-install solution for connecting conduit to electrical boxes or enclosures. Made from zinc die-cast with an aluminum finish, it’s built for robustness and corrosion resistance. Its tri-combo screw ensures a secure, reliable connection for AC, MC, FMC, or RWFMC cables, suitable for steel or aluminum conduit. Rated highly with a 4.5-star rating, users praise its simplicity, quality, and sleek appearance, especially for visible installations like EV chargers and Tesla setups. It’s a versatile, UL and CSA-listed connector that’s ready for demanding electrical applications.

Best For: Professional electricians and electrical contractors seeking a durable, easy-to-install conduit connector for secure connections in visible or demanding electrical installations.

Pros:

- Made from durable zinc die-cast with corrosion-resistant aluminum finish

- Easy to install with tri-combo screw for secure fastening

- Highly rated for quality, sleek appearance, and versatility in various conduit and cable applications

Cons:

- Sold as a single piece, which may require multiple purchases for larger projects

- Limited to 3/4-inch conduit size, not suitable for other sizes without additional fittings

- Discontinued status not indicated, so availability might vary depending on stock

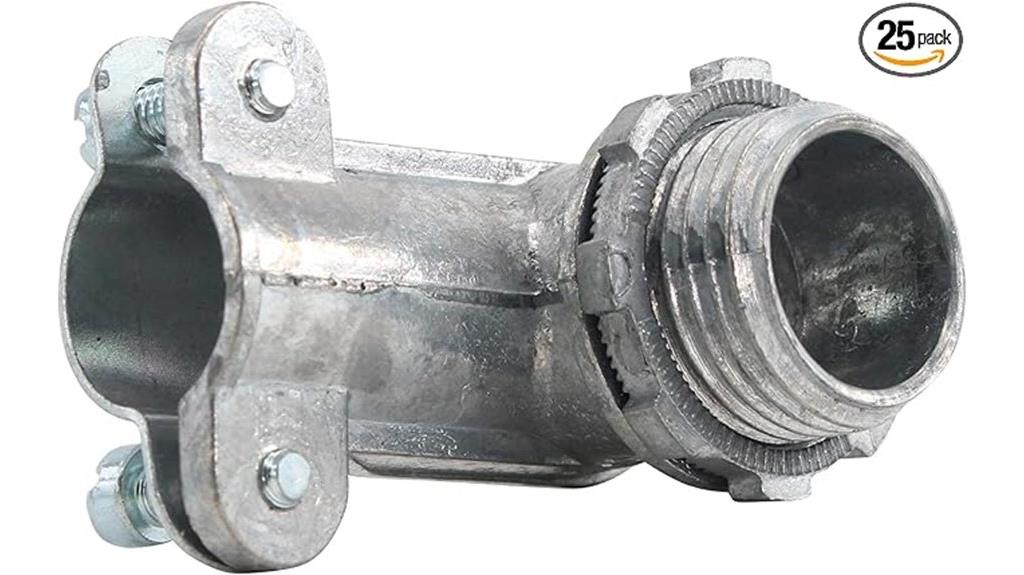

Sigma Electric Flex 90-Degree Squeeze Connector (1-Pack)

Designed for professional electricians and DIY enthusiasts alike, the Sigma Electric Flex 90-Degree Squeeze Connector guarantees secure and reliable cable termination in dry locations. It’s ideal for connecting FMC/RWFMC, AC, or MC cables to 1-inch knockout metal boxes or enclosures, especially when making 90-degree bends. Made from durable zinc die-cast with an aluminum finish, it’s built to meet electrical standards and is CSA certified. The connector features tri-combo screws for easy installation, though some units may arrive with missing screws. Compact and lightweight, it’s a practical choice for ensuring a tight, corrosion-resistant connection in conduit systems.

Best For: professional electricians and DIY enthusiasts seeking a reliable, easy-to-install connector for secure conduit terminations in dry locations.

Pros:

- Made of durable zinc die-cast with an aluminum finish for corrosion resistance

- Certified CSA for safety and compliance with electrical standards

- Features tri-combo screws for straightforward installation

Cons:

- Some units may arrive with missing screws, requiring additional replacement parts

- Only suitable for dry location applications, limiting versatility

- Slightly compact size may be challenging to grip for some users during installation

SIGMA PROCONNEX Flex 90° Squeeze Connector (3/4-inch)

For professionals seeking a reliable and easy-to-install solution, the SIGMA PROCONNEX Flex 90° Squeeze Connector (3/4-inch) stands out with its sturdy zinc die-cast construction and corrosion-resistant aluminum finish. It effectively terminates FMC, RWFMC, AC, or MC cables to 3/4-inch knockout boxes or enclosures, making it ideal for dry environments. Its design allows for smooth 90-degree bends while ensuring a secure, durable connection. With features like tri-combo screws for versatile fastening and easy-open construction for wiring, this connector provides a high-quality, long-lasting solution. Certified CSA compliant, it’s highly rated for performance and value in professional electrical setups.

Best For: Professional electricians and contractors seeking a durable, easy-to-install connector for terminating FMC, AC, or MC cables in dry environments with reliable 90-degree bends.

Pros:

- Robust zinc die-cast construction ensures long-lasting durability and strength

- Easy-open design facilitates quick wiring and installation in tight spaces

- Versatile tri-combo screws allow for secure termination of various conduit types

Cons:

- May be slightly heavier than plastic alternatives, impacting handling in some applications

- Designed specifically for dry locations, limiting use in damp or wet environments

- Requires threading and proper fitting, which may be less suitable for novice users

Bridgeport 801-DC2 MC Flex Conduit Connector (25-Pack)

If you’re tackling a large electrical project that demands reliable and durable conduit connections, the Bridgeport 801-DC2 MC Flex Conduit Connector in a 25-pack offers an excellent solution. This 90-degree, 3/8-inch connector is made from durable die-cast zinc with screw terminals, ensuring secure and long-lasting connections. Its silver finish and non-insulated design make it suitable for flexible metallic conduit, especially for applications like LED lighting. With positive reviews for fit and ease of installation, this pack is cost-effective for multiple setups. Certified to meet RoHS, Reach, and LEED standards, it combines quality with environmental safety, making it a dependable choice for professional electrical work.

Best For: professional electricians and contractors seeking reliable, durable conduit connectors for large-scale electrical installations and projects requiring flexible metallic conduit.

Pros:

- Made from durable die-cast zinc with secure screw terminals for long-lasting connections

- Cost-effective pack of 25 pieces ideal for bulk projects and multiple installations

- Certified to meet RoHS, Reach, and LEED standards ensuring environmental safety and compliance

Cons:

- Non-insulated design may require additional insulation in sensitive applications

- Limited to 3/8-inch flexible metallic conduit, not compatible with other sizes or types

- Slightly heavier weight per piece (0.384 ounces), which may be a consideration for extensive installations

Stainless Steel Water Heater Connector (2 Pack)

The Stainless Steel Water Heater Connector (2 Pack) stands out as an ideal choice for homeowners and DIY enthusiasts seeking a durable, flexible, and leak-free solution for water heater hookups. Made from premium grade 304 stainless steel, these connectors resist corrosion and handle high pressure up to 250 PSI. Their corrugated design offers flexibility, preventing kinks and easing installation in tight spaces. With FIP (1 NPT) connectors on each end, no Teflon tape is needed for a secure seal. Certified NSF-61 and UPC approved, they ensure safe, leak-free connections, backed by a 10-year warranty and positive customer reviews.

Best For: homeowners, DIY enthusiasts, and plumbers seeking a reliable, flexible, and corrosion-resistant connection for water heaters, softeners, and irrigation systems.

Pros:

- Made of premium grade 304 stainless steel for durability and corrosion resistance

- Flexible corrugated design prevents kinking and simplifies installation in tight spaces

- No Teflon tape needed due to secure FIP (NPT) connections, ensuring leak-free performance

Cons:

- May be too rigid for applications requiring highly flexible hoses

- Slightly heavier than plastic connectors, which could be a concern in some setups

- Limited to specific pressure ratings; not suitable for extremely high-pressure systems beyond 250 PSI

Hubbell-Raco Squeeze Connector for Metal Conduit (Pack of 10)

Among the top flex connectors, the Hubbell-Raco Squeeze Connector for Metal Conduit stands out with its rugged zinc alloy steel construction and 90-degree bend, making it ideal for ensuring secure, durable connections in flexible metal conduit and armored cable installations. Designed for 3/4-inch sizes, it features a twist connector type with screw terminals, providing a reliable grip. Certified by CSA and UL, it withstands temperatures up to 257°F and handles voltages up to 600V AC. Packaged in sets of 10, these connectors are perfect for projects requiring multiple fittings, offering strength and dependability for both professional and DIY electrical work.

Best For: Professional electricians and DIY enthusiasts seeking durable, reliable connectors for flexible metal conduit and armored cable installations.

Pros:

- Rugged zinc alloy steel construction ensures durability and mechanical protection

- Certified by CSA and UL for safety and compliance

- Easy to install with screw terminal and 90-degree bend design

Cons:

- Only available in 3/4-inch size, limiting versatility for other diameters

- Packaged in sets of 10, which may be excessive for small projects

- Non-insulated design may require additional insulation or protection in certain environments

1/2 Inch Liquid Tight Connector PVC Electrical Conduit Fittings (30 Pcs)

Ideal for professionals and DIY enthusiasts alike, the 1/2 Inch Liquid Tight PVC Electrical Conduit Fittings (30 Pcs) stand out with their easy-to-install design and reliable water-tight seal. Made from quality PVC and iron, these fittings are flexible, allowing for quick 180-degree angle changes by simply pulling and rotating. They connect easily to electrical boxes and conduits without tools, saving time and effort. Suitable for a wide range of applications like HVAC, marine, and electrical systems, this bulk pack offers durability and convenience. With high ratings and positive feedback, these fittings deliver dependable, long-term performance for any project.

Best For: DIY enthusiasts, electricians, and professionals seeking easy-to-install, reliable conduit fittings for various electrical and mechanical projects.

Pros:

- Easy to install without additional tools, saving time and effort

- Flexible 180-degree connectors for versatile angle adjustments

- Durable PVC and iron construction with water-tight sealing for long-term use

Cons:

- Limited to 1/2 inch conduit size, may not fit larger applications

- Nonmetallic design might be less suitable for highly corrosive environments

- Bulk packaging may be excessive for small-scale or one-time projects

10 Pack Squeeze Connector 3/4-inch Conduit Fittings

If you’re tackling a large wiring project, the Pack Squeeze Connector 3/4-inch Conduit Fittings stand out for their ease of installation and durability. These fittings come in a pack of ten, making them cost-effective for big jobs. Made from zinc die-cast material, they resist corrosion, wear, and deformation, ensuring long-lasting connections. Designed for quick, screwless installation, they simplify connecting flexible metal conduits and cables like RWFM. Suitable for indoor use across various industries, they provide reliable, flexible connections in tight spaces. With high customer ratings and durable construction, these fittings are a smart choice for professional, secure wiring setups.

Best For: professional electricians, contractors, and DIY enthusiasts undertaking large-scale indoor wiring projects requiring durable, easy-to-install conduit fittings.

Pros:

- Quick, screwless installation saves time and reduces labor effort

- Made from corrosion-resistant zinc die-cast material for durability

- Suitable for various cables and flexible conduits, offering versatility

Cons:

- Designed primarily for indoor use only, limiting outdoor applications

- Reversible locking nut may require some initial familiarity for proper installation

- Not suitable for environments with high moisture or exposure to harsh elements

Halex – 3/8 (1/2 KO) Flex 90DEG Connector – 35/CCP

The Halex 3/8 (1/2 KO) Flex 90° Connector stands out for those seeking a reliable, versatile solution to connect flexible metal conduit or cables to steel outlet boxes or enclosures. Designed for indoor use, it provides a secure, tight bond that guarantees system safety. Made from durable die-cast zinc alloy with zinc-plated steel clamps, it resists corrosion and withstands demanding conditions. Its reversible locknut and ability to cut through protective coatings facilitate quick grounding and installation. Compatible with 3/8 and 1/2 inch knockout holes, this connector supports professional, clean setups and is sold in convenient packs of 35.

Best For: professional electricians and DIY enthusiasts seeking a durable, versatile connector for indoor flexible conduit and cable installations.

Pros:

- Made from high-strength die-cast zinc alloy with corrosion-resistant zinc plating for durability

- Reversible locknut and cutting capability facilitate quick grounding and easy installation

- Fits both 3/8 inch and 1/2 inch knockout holes, offering versatile compatibility

Cons:

- Designed solely for indoor use, limiting outdoor applications

- Non-insulated connector may require additional insulation in some setups

- Slightly heavier weight per piece (1.35 ounces), which may impact handling during bulk installations

Hubbell-Raco Squeeze Connector, Pack of 10

Hubbell-Raco’s Squeeze Connector, Pack of 10, stands out as a top choice for professionals seeking reliable connections with flexible metal conduit and armored cable. Made from die-cast zinc, it offers durability and corrosion resistance thanks to its electro zinc plating. Designed for 1-inch flexible or armored cables, this uninsulated connector provides a secure, straight connection to raceways. Its all-malleable iron construction ensures mechanical protection, meeting UL and CSA standards. Whether you’re installing new systems or maintaining existing ones, this pack of ten connectors delivers consistent performance and ease of use, making it a dependable component for your electrical projects.

Best For: electrical professionals and contractors needing reliable, corrosion-resistant connectors for flexible metal conduit and armored cable installations.

Pros:

- Durable die-cast zinc construction for long-lasting performance

- Electro zinc plating enhances corrosion resistance

- UL listed and CSA certified for safety and compliance

Cons:

- Uninsulated design may require additional insulation measures

- Suitable primarily for 1-inch cables, limiting versatility for other sizes

- May require specific tools for installation due to design features

Factors to Consider When Choosing Flex Connectors

When selecting a flex connector, I focus on material compatibility and durability to make certain of long-lasting performance. I also consider size options, environmental resistance, and ease of installation to match specific needs. Finally, I check for proper certification and safety standards to guarantee reliable, safe operation.

Material Compatibility and Durability

Choosing the right flex connector hinges on guaranteeing its material matches the conduit or cable it’s paired with, preventing compatibility issues that could compromise safety or performance. For example, use zinc die-cast connectors with steel conduits, or PVC for outdoor cables. Opt for corrosion-resistant materials like zinc, stainless steel, or PVC to withstand harsh environments and extend the connector’s lifespan. Always verify the temperature rating—ideally 25°C or higher—to ensure it suits your system’s operating conditions. Additionally, select connectors with robust construction, such as heavy-duty die-cast zinc or stainless steel, to handle mechanical stresses and prevent damage over time. Finally, confirm the connector’s compliance with safety standards like UL or CSA, guaranteeing durable, reliable performance that meets industry regulations.

Size and Fitting Options

Selecting the right size and fitting options for flex connectors is essential to guarantee a secure and reliable connection. Flex connectors come in various sizes, typically matching conduit diameters like 1/2-inch, 3/4-inch, and 1-inch, to ensure a proper fit. Choosing the correct size helps maintain electrical safety, prevents leaks, and assures compatibility with existing conduit or cable systems. Many connectors feature adjustable or screw-in designs, making installation easier and fastening more secure across different environments. It’s also important to take into account the specific conduit type, such as FMC, rigid, or liquid-tight flexible conduit, as this influences fitting options. Always verify the knockout or opening size of your electrical box to select a connector that provides a tight seal and meets code requirements.

Environmental Resistance Features

Are you aware of how essential environmental resistance features are when picking flex connectors? These features ensure your connections withstand harsh conditions. I look for connectors made from corrosion-resistant materials like stainless steel or die-cast zinc, which resist moisture and corrosion. Checking UL and CSA listings helps confirm their suitability for outdoor or rugged environments. Weatherproof designs, such as rubber gaskets or liquid-tight seals, prevent water ingress, protecting your setup. Temperature ratings are critical; I match them to the environment—whether cold or hot—to avoid failures. Protective coatings or finishes also boost durability against salt, chemicals, and UV radiation. By prioritizing these resistance features, I ensure my connections remain secure and reliable, even under challenging environmental conditions.

Ease of Installation

Ease of installation is a crucial factor to contemplate because it can considerably reduce setup time and effort. I recommend choosing flex connectors with smooth, snag-free surfaces for effortless conduit or cable insertion. Opt for designs that feature simple, tool-free tightening mechanisms like twist-on or push-in styles, which speed up installation without extra tools. Ensuring the connector’s size matches the conduit or cable diameter precisely helps achieve a snug fit without modifications. Additionally, select connectors with clear, accessible locking features to simplify securing connections. Considering corrosion-resistant materials such as zinc or stainless steel also makes installation smoother over time, especially in challenging environments. Overall, the easier the connector is to install, the more efficient and reliable your wiring process will be.

Certification and Safety Standards

Certification and safety standards play an essential role in ensuring that your flex connectors meet the necessary safety and performance requirements. When selecting connectors, I always look for products certified by recognized organizations like UL and CSA. These certifications mean the connectors have undergone rigorous testing for electrical safety, mechanical durability, and environmental resistance, reducing the risk of failure. Labels on the product confirming compliance provide reassurance that the connector adheres to industry benchmarks. Certification also guarantees that the connector meets specific voltage, temperature, and environmental ratings, ensuring safe installation. Using certified connectors not only enhances safety but also minimizes liability by confirming the product complies with electrical codes and regulations. Prioritizing certification helps me ensure reliable, safe connections in all my projects.

Flexibility and Bend Radius

When selecting a flex connector, considering its bend radius is vital to guarantee reliable and safe wiring. The bend radius indicates the smallest curve the connector can handle without damaging the conduit or wiring, as specified by the manufacturer. Connectors with a tighter bend radius are ideal for tight spaces and sharp turns. However, bending beyond this limit can cause stress, risking damage or failure of the wiring. The flexibility of a connector depends on its material and construction; braided or corrugated designs offer greater bend capability. Choosing a connector with an appropriate bend radius ensures that wiring remains secure and functional, reduces strain on the electrical system, and minimizes potential issues caused by improper bending. This factor is essential for both safety and long-term performance.

Corrosion and Weatherproofing

Choosing the right flex connector for outdoor or harsh environments requires careful attention to corrosion and weatherproofing features. I recommend selecting connectors made from corrosion-resistant materials like die-cast zinc or stainless steel, which stand up well against the elements. Look for models with weatherproof or sealed designs, such as those with rubber gaskets or tight-fitting nuts, to block water ingress and moisture buildup. It’s also wise to choose connectors rated for outdoor or wet locations, meeting standards like UL 514B, CSA, or IP ratings. The finish matters too—zinc plating or protective coatings add extra corrosion resistance. Finally, proper installation techniques, including sealing threaded joints with appropriate compounds or tape, help maintain weatherproofing and prevent corrosion over time.

Price and Value Considerations

Have you considered how the balance between cost and quality impacts the long-term value of flex connectors? It’s essential to compare unit prices and total costs, especially when buying in bulk, to find the best deal for your project. While cheaper connectors may save money upfront, they often lack durability and may need frequent replacement, increasing overall costs. High-quality connectors made from corrosion-resistant materials like zinc or stainless steel tend to last longer, reducing maintenance expenses. Additionally, selecting connectors with safety certifications like UL or CSA can prevent electrical failures and improve safety, saving you money in the long run. By weighing durability and performance features against cost, you ensure you choose connectors that deliver true value tailored to your specific needs.

Frequently Asked Questions

What Are the Primary Differences Between Metal and PVC Flex Connectors?

Metal flex connectors are durable, resistant to heat, and provide a secure, long-lasting connection, making them ideal for high-stress or outdoor applications. PVC flex connectors, on the other hand, are lightweight, flexible, and easier to install, but they may not withstand extreme temperatures or harsh conditions as well. I recommend choosing metal for heavy-duty needs and PVC for simpler, indoor tasks.

How Do Environmental Conditions Affect Flex Connector Longevity?

Environmental conditions can make or break the lifespan of flex connectors. I’ve seen how extreme temperatures, moisture, and exposure to chemicals cause materials to degrade faster, leading to leaks or failures. Even UV rays from sunlight can weaken plastic or rubber parts over time. To guarantee longevity, I always recommend selecting connectors designed for specific environments and performing regular inspections—neglecting these factors could lead to unexpected, costly failures.

Are There Specific Flex Connectors Recommended for Outdoor Versus Indoor Use?

Yes, I recommend using weatherproof, UV-resistant flex connectors for outdoor applications to withstand harsh conditions. For indoor use, standard flexible connectors work well, offering ease of installation and reliable connections. I always choose connectors designed specifically for the environment, ensuring durability and safety. If you’re unsure, consult manufacturer guidelines or a professional to select the best type for your setting, so your connections stay secure and long-lasting.

What Safety Standards Should Flex Connectors Meet in 2025?

In 2025, flex connectors should meet safety standards like UL, IEC, and CSA certifications to guarantee they’re safe and reliable. I always check for these markings before installation, especially for outdoor use where weather resistance is essential. Making certain of compliance with these standards helps prevent electrical hazards, short circuits, and fire risks. I recommend choosing connectors that clearly display these certifications for peace of mind and long-term safety.

How Do Installation Techniques Impact Connector Performance and Security?

Have you ever wondered how a small mistake during installation can compromise a connector’s performance? I’ve found that proper techniques—such as avoiding excessive bending, ensuring correct alignment, and securing connectors tightly—are essential. These practices prevent strain, reduce wear, and maintain a secure connection over time. When I install flex connectors carefully, I’m confident they’ll perform reliably and stay secure, preventing future issues and ensuring safety.

Conclusion

Choosing the right flex connector can truly transform your projects, ensuring seamless and secure connections every time. With so many options available, it’s like having a toolbox filled with magic tricks that make installation effortless. Remember, the perfect connector isn’t just a tool—it’s your secret weapon against leaks, failures, and headaches. Invest wisely, and you’ll enjoy peace of mind that lasts longer than even the most stubborn pipe dreams.