Hidden costs of iron and manganese treatment often sneak in through ongoing chemical reactions, maintenance needs, and unexpected equipment repairs. These can lead to higher chemical consumption and frequent system checkups, raising your long-term expenses. To avoid this, you should monitor water chemistry regularly, perform scheduled equipment maintenance, and upgrade to corrosion-resistant parts. Stay aware of these hidden factors, and you’ll be better prepared to keep your system efficient and cost-effective over time.

Key Takeaways

- Unanticipated chemical reactions can create byproducts, increasing chemical costs and requiring additional system adjustments.

- Regular maintenance of filters and oxidation systems prevents costly equipment repairs and prolongs lifespan.

- Long-term expenses include ongoing chemical use and system repairs, often underestimated initially.

- Proper water chemistry monitoring and equipment upgrades reduce unnecessary chemical consumption and operational costs.

- Vigilant planning and system oversight help avoid hidden expenses by identifying issues early and maintaining efficiency.

Common Hidden Expenses in Iron and Manganese Water Treatment

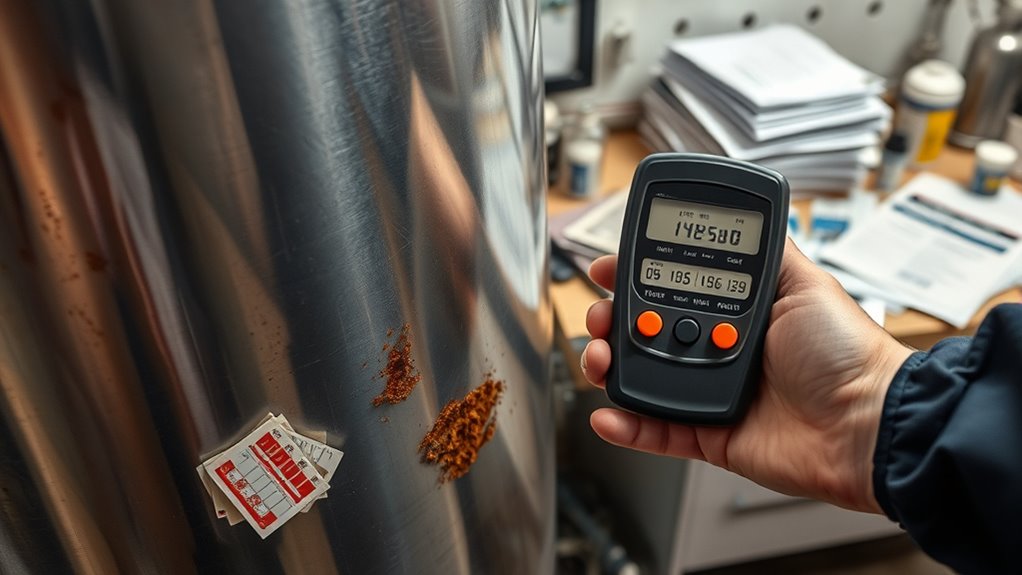

While the upfront costs of iron and manganese treatment might seem straightforward, several hidden expenses can catch you off guard. One major factor is the ongoing chemical reactions that occur during treatment, which can lead to unexpected byproducts and increased chemical consumption. These reactions may require additional adjustments to your system, adding to overall costs. Maintenance routines also play a significant role; equipment like filters and oxidation systems need regular upkeep to prevent clogging and ensure efficiency. Neglecting these routines can lead to costly repairs or replacements down the line. Plus, unanticipated expenses from frequent chemical additions and system upkeep can quickly escalate, making initial estimates seem much lower than actual long-term investment. Being aware of these aerosol effects helps you plan better and avoid surprises.

Strategies to Minimize Long-Term Costs and Maintain Efficiency

Implementing proactive maintenance and monitoring strategies is essential to keep your iron and manganese treatment system efficient and cost-effective over the long term. Regular inspections help identify issues like chemical corrosion early, preventing costly repairs and system failures. Monitoring water chemistry ensures ideal chemical dosing, reducing unnecessary chemical use and minimizing energy consumption. To maintain efficiency, keep equipment clean and avoid buildup that can hinder flow and increase energy demands. Consider upgrading to corrosion-resistant materials to reduce chemical corrosion and extend equipment lifespan. Properly balancing treatment chemicals also prevents overuse, saving money and reducing long-term operational costs. Additionally, understanding the cost factors associated with your system can help you plan for potential expenses and avoid unexpected costs. By staying vigilant and maintaining your system, you’ll avoid hidden expenses and ensure consistent, efficient performance for years to come.

Frequently Asked Questions

How Often Should I Perform Maintenance on Treatment Systems?

You should perform maintenance on your treatment system at least every 3 to 6 months. During these visits, check system calibration to ensure accurate operation and test water quality. Replenish chemicals as needed to prevent inefficiencies and hidden costs. Regular maintenance helps avoid system breakdowns, maintains effective iron and manganese removal, and keeps your water safe. Stay proactive, and schedule routine inspections to keep everything running smoothly.

What Are Signs My System Requires Repair or Replacement?

You’ll know your system needs repair or replacement if it shows repair indicators like decreased water flow, persistent iron or manganese stains, or unusual odors. These signs suggest your system’s lifespan might be nearing its end or that repairs are necessary. Addressing these issues early helps avoid costly replacements and keeps your system functioning efficiently. Regular maintenance also helps you catch repair indicators before they become major problems.

Are There Eco-Friendly Options to Reduce Treatment Costs?

Yes, you can choose eco-friendly options like using natural filtration methods or investing in energy-efficient treatment systems. These cost-effective solutions reduce chemical use and energy consumption, helping you save money while protecting the environment. Consider installing green filters, such as biofiltration or activated carbon, which lower chemical costs and minimize waste. By opting for sustainable choices, you maintain water quality without harming the planet and keep your treatment expenses manageable.

How Do Water Quality Changes Affect Treatment Expenses?

Imagine water chemistry as a shifting landscape—you must adapt to its changing terrain. As water quality varies, so do your treatment expenses, rising like unpredictable tides. Fluctuations in levels of iron and manganese demand different approaches, impacting costs. To stay afloat, you need cost-effective solutions tailored to these changes, such as real-time monitoring and adjustable treatment methods, ensuring your system remains efficient despite the ever-changing water chemistry.

Can DIY Maintenance Prevent Hidden Costs?

Yes, DIY maintenance can prevent hidden costs by catching issues early, reducing chemical corrosion risks, and maintaining energy efficiency. Regularly inspecting your system, cleaning filters, and monitoring water quality helps avoid expensive repairs and replacements later. Staying proactive ensures your treatment system runs smoothly, saving you money over time. Just remember, proper knowledge is key—if you’re unsure, consulting professionals can help avert costly mistakes.

Conclusion

While tackling iron and manganese treatment might seem straightforward, overlooking hidden costs can lead to surprises—like rising expenses or system inefficiencies. By understanding these hidden expenses and adopting smart strategies, you avoid costly mistakes and enjoy cleaner water with less hassle. Think of it as balancing the initial investment against ongoing savings—like planting a tree today to enjoy shade tomorrow. Stay informed, plan wisely, and your water system will serve you well, both now and in the future.