Many beginners mistakenly think all carbon materials work the same, but regular carbon mainly traps contaminants through adsorption, while catalytic carbon actually promotes chemical reactions to break down pollutants. They might assume catalytic carbon is always better, but it’s more expensive and sensitive to environment factors like humidity. Also, choosing the right type depends on your specific needs and maintenance plans. Keep exploring to understand these differences better and make smarter choices.

Key Takeaways

- Catalytic carbon is designed for chemical reactions, not just adsorption like regular carbon.

- It often lasts longer but requires more maintenance and regular filter regeneration.

- Catalytic carbon performs better in removing complex odors and gases, especially in dry conditions.

- Standard carbon is more cost-effective but less durable and less effective against certain chemical vapors.

- Environmental factors like humidity and chemical presence can significantly impact catalytic carbon’s efficiency.

Misunderstanding the Basic Composition and Structure of Carbon and Catalytic Carbon

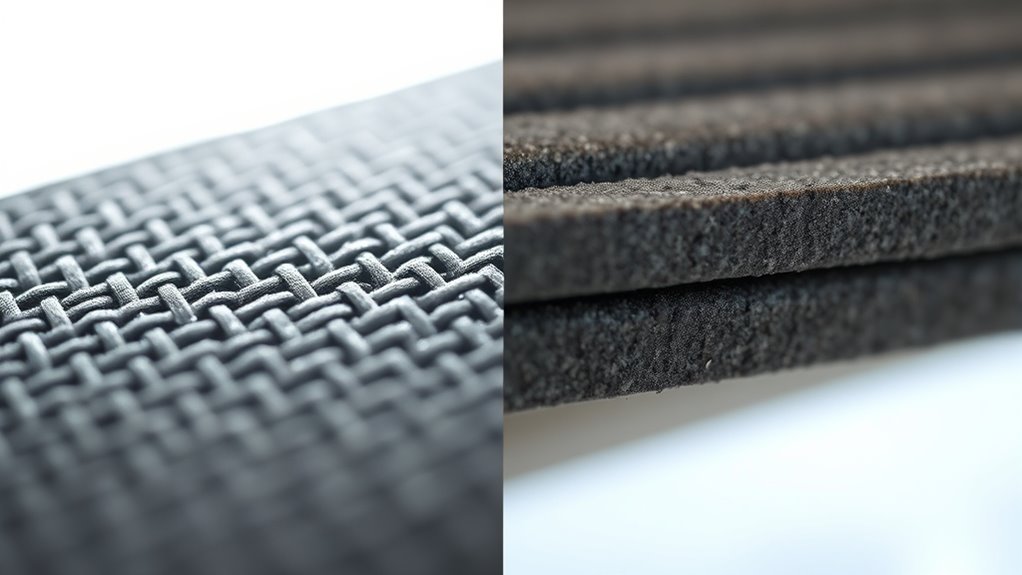

Many people confuse regular carbon with catalytic carbon because they overlook their fundamental differences in composition and structure. Regular carbon, such as charcoal or graphite, has a simple chemical structure with layers of carbon atoms arranged in hexagonal patterns. Its material composition is mainly pure carbon, with minimal impurities. Catalytic carbon, on the other hand, features a specialized chemical structure designed for catalytic activity. Its material composition includes activated carbon with specific surface properties and sometimes other elements or compounds that enhance its function. This unique structure creates a high surface area, allowing it to facilitate chemical reactions more effectively. Recognizing these differences helps you understand why each material performs differently, especially in applications like filtration or catalysis.

Confusing the Purposes and Applications of Each Material

Because regular carbon and catalytic carbon serve different functions, it’s easy to confuse their purposes, but understanding their distinct applications is crucial. Regular carbon primarily relies on adsorption mechanisms, trapping contaminants on its surface through physical or chemical interactions. Its chemical properties, such as high surface area, make it effective for filtration and purification tasks like water treatment and odor control. In contrast, catalytic carbon is designed to facilitate chemical reactions, often breaking down pollutants rather than just trapping them. Its unique chemical properties enable it to serve as a catalyst in processes like air purification, where it helps convert harmful gases into less toxic substances. Recognizing these differences ensures you select the right material for your specific needs and avoid common mistakes in application. Additionally, understanding the UV radiation risks associated with certain tanning methods underscores the importance of skin protection and choosing safer alternatives.

Assuming Catalytic Carbon Is Always Superior for Air Purification

While it’s tempting to assume catalytic carbon is the best choice for all air purification needs, this isn’t always the case. Catalytic carbon often offers better material durability, meaning it lasts longer and maintains effectiveness over time. However, it can be more expensive upfront, impacting cost efficiency, especially for smaller or budget-conscious setups. In some situations, traditional carbon may perform sufficiently and be more economical. Additionally, catalytic carbon is sensitive to certain conditions, such as high humidity or specific chemicals, which can reduce its effectiveness. Moreover, the technology used in different carbon types can influence their suitability for various environments, making it important to evaluate your specific needs. Hence, you shouldn’t automatically favor catalytic carbon without considering your specific environment, durability requirements, and budget constraints. Making an informed choice involves weighing both material durability and cost efficiency against your unique air purification needs.

Overlooking the Importance of Specific Use Cases and Environments

Choosing the right carbon type depends heavily on your specific use case and environment. Material versatility plays a key role in selecting between standard and catalytic carbon, as some environments demand specialized properties. Environmental factors like humidity, temperature, and contaminant types influence performance profoundly. For example, catalytic carbon works well in environments with complex odors or chemical vapors, but may underperform in moist conditions. Conversely, activated carbon excels at adsorbing gases in dry settings. Overlooking these details can lead to ineffective filtration or wasted investment. Always analyze your environment’s unique conditions and the variety of materials available. Proper understanding of environmental conditions helps in selecting the most suitable carbon type for your application, maximizing efficiency and longevity while avoiding common pitfalls caused by neglecting specific use cases.

Underestimating the Maintenance and Longevity Differences

Many underestimate how markedly maintenance requirements and lifespan differ between standard and catalytic carbon. Maintenance expectations for catalytic carbon are generally higher because it requires more frequent inspections and filter replacements to maintain efficiency. Conversely, standard carbon often needs less attention but may not last as long overall. Longevity factors play a significant role; catalytic carbon’s lifespan depends on proper upkeep and the specific use case, but it can last longer with regular maintenance. Proper understanding of filter regeneration processes is essential for maximizing lifespan and performance. Underestimating these differences can lead to unexpected costs and system failures. You should carefully consider how often you’ll need to replace or service each type, balancing initial costs against ongoing maintenance. Recognizing these distinctions helps you plan better and avoid surprises, ensuring your filtration system stays effective and cost-efficient over time.

Frequently Asked Questions

Can Catalytic Carbon Be Reused After Its Adsorption Capacity Is Exhausted?

Yes, catalytic carbon can be reused after its adsorption capacity is exhausted. You need to perform a regeneration process, which involves heating or treating the material to restore its adsorption capacity. This process helps remove the accumulated contaminants, allowing you to reuse the catalytic carbon effectively. Keep in mind that the effectiveness of regeneration depends on the extent of fouling and the specific regeneration method used.

How Do Cost Differences Impact Choosing Between Regular and Catalytic Carbon?

Choosing between regular and catalytic carbon is like weighing a tightrope walk—you need to balance costs carefully. Regular carbon is cheaper initially but wears out faster, affecting economic considerations over time. Catalytic carbon costs more upfront but offers greater material durability and longer lifespan, often reducing replacement expenses. Your decision hinges on your budget and long-term maintenance needs, making catalytic carbon worth it if durability and lower operational costs matter most.

Are There Health Risks Associated With Improper Handling of Catalytic Carbon?

Improper handling of catalytic carbon can pose health hazards, such as inhaling dust or fumes that may irritate your respiratory system. To stay safe, always wear gloves, masks, and eye protection, and handle it in well-ventilated areas. Following handling precautions minimizes risks, preventing potential health issues. If you’re unsure, consult the material safety data sheet (MSDS) for specific safety guidelines to protect yourself effectively.

Does the Environmental Impact Differ Significantly Between the Two Materials?

Think of carbon and catalytic carbon as two different footprints on the environment’s path. Catalytic carbon often leaves a lighter mark, thanks to its recycling benefits, reducing waste and conserving resources. Its environmental footprint is usually smaller, making it a greener choice. While both impact the planet, choosing catalytic carbon helps you tread more lightly, supporting sustainability and cleaner air for everyone.

How Do Temperature and Humidity Affect the Performance of Catalytic Carbon?

Temperature and humidity can considerably influence the performance of catalytic carbon by affecting its adsorption efficiency and temperature stability. Higher temperatures may diminish adsorption efficiency, making it less effective at trapping contaminants, while extreme humidity levels can clog or deactivate the material. To guarantee ideal performance, you should monitor environmental conditions and maintain proper humidity levels, which helps catalytic carbon retain its temperature stability and maximize its ability to purify air or water.

Conclusion

Now that you see through the fog of misconceptions, imagine yourself holding both carbon and catalytic carbon, each with its unique glow. You realize that choosing the right one is like selecting the perfect key for a lock—depends on the task, environment, and longevity. With this clarity, you’ll make smarter decisions, ensuring your air stays clean and fresh. No more guessing—just informed choices that breathe new life into your space.