When choosing between parallel and series flow configurations for multi-stage systems, consider your goals. Use series arrangements if you need precise control, process consistency, and stepwise processing. Opt for parallel setups to maximize throughput, reduce processing time, and save space. Think about energy use, pressure drops, and flow management. The right choice depends on your specific priorities. Exploring further will help you understand how to optimize your system for better performance.

Key Takeaways

- Series configurations offer precise control and consistency, ideal for sequential chemical reactions or purification processes.

- Parallel setups maximize throughput and reduce processing time, suitable for high-volume operations.

- Series arrangements involve higher pressure drops, increasing energy consumption but enhancing process control.

- Parallel configurations typically have lower pressure drops, potentially reducing energy costs and space requirements.

- The choice depends on process goals: series for accuracy and control; parallel for throughput and efficiency.

Have you ever wondered how the right flow configuration can optimize your system’s performance? When dealing with multi-stage systems, selecting between parallel and series arrangements can markedly impact efficiency, throughput, and overall process optimization. Understanding fluid dynamics in each setup helps you make informed decisions that align with your operational goals. In process optimization, the way fluids move through your system determines not only how effectively materials are processed but also how energy is consumed and how downtime is minimized.

Optimizing flow configuration enhances efficiency, throughput, and process control in multi-stage systems.

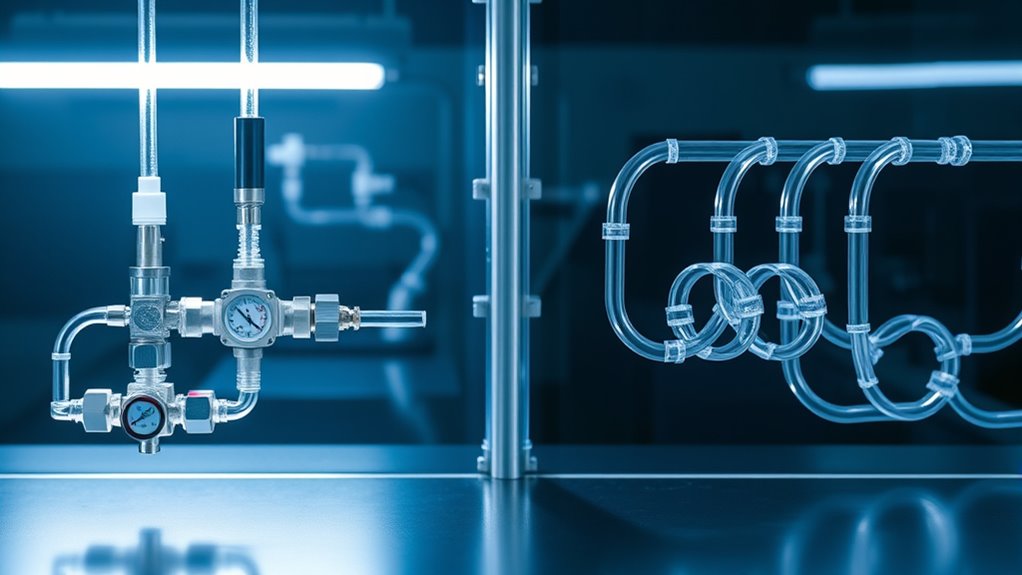

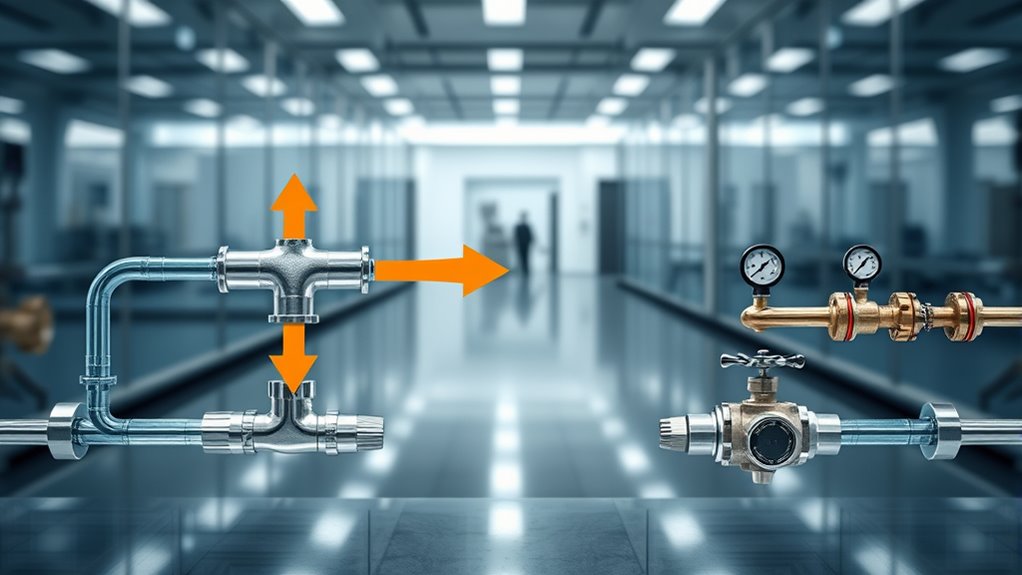

In a series configuration, fluids pass through each stage sequentially, meaning the output of one stage becomes the input for the next. This arrangement allows for precise control over each process step, often resulting in a high degree of consistency and uniformity. It’s particularly useful when each stage needs to build upon the previous one, such as in multi-step chemical reactions or sequential purification processes. From a fluid dynamics perspective, series setups often involve higher pressure drops, as the fluid must push through each consecutive stage, which can increase energy consumption. However, this setup simplifies process control, since the flow remains constant throughout the system, and allows for better maintenance of process conditions at each step.

Conversely, a parallel configuration splits the flow into multiple paths, with fluids moving through different stages simultaneously. This setup can drastically enhance throughput and reduce overall processing time, making it ideal for high-volume operations. In terms of process optimization, parallel flow allows you to handle larger volumes without increasing the size of individual components, which can save costs and space. Fluid dynamics in parallel systems involve managing flow distribution, ensuring each pathway receives the appropriate flow rate. Proper balancing prevents bottlenecks and uneven processing. Parallel configurations also tend to have lower pressure drops compared to series arrangements, resulting in potentially reduced energy costs.

Choosing between these configurations depends on your system’s specific needs. If your process demands tight control, high precision, and stepwise processing, series setups often work best. But if maximizing throughput and minimizing processing time are your priorities, parallel configurations might be more advantageous. Both setups demand an understanding of fluid dynamics to optimize flow paths, pressure drops, and flow rates. By carefully analyzing these factors, you can enhance process efficiency and ensure your system operates smoothly. Ultimately, your choice should focus on how each configuration aligns with your process goals, energy efficiency, and space constraints, ensuring the best possible process optimization tailored to your application.

Frequently Asked Questions

How Do Cost Considerations Influence Flow Configuration Choices?

Cost considerations heavily influence your flow configuration choices. You’ll prioritize cost efficiency by choosing a setup that minimizes expenses, whether through reduced energy consumption or lower maintenance costs. Parallel configurations often offer easier setups and flexibility, but may have higher initial costs. Series setups might save on initial investment but could increase setup complexity and maintenance costs. Balancing these factors helps you select the most economical option for your system.

What Are the Environmental Impacts of Different Flow Setups?

While parallel setups often reduce energy use, they can increase fluid dynamics complexity, impacting environmental footprint. Series configurations may streamline flow, lowering emissions, but might cause higher energy consumption and waste. Your choice influences resource efficiency and pollution levels, with each setup bearing distinct environmental impacts. You must weigh these factors carefully, considering how fluid dynamics and system design directly shape your overall environmental footprint.

How Does System Reliability Differ Between Parallel and Series Configurations?

You’ll find that parallel systems offer higher reliability because they include redundancy planning, allowing the system to continue functioning if one pathway fails. Series configurations, on the other hand, have lower fault tolerance since a single fault can halt the entire process. When choosing between them, consider your reliability needs; parallel setups provide better fault tolerance, reducing downtime and ensuring consistent performance.

Can Hybrid Flow Configurations Optimize System Performance?

Like a skilled conductor blending instruments, you can enhance system performance with hybrid flow configurations. They create flow synergy by combining parallel and series elements, giving you configuration flexibility to adapt to varying demands. This setup enhances efficiency, reliability, and resilience, allowing you to fine-tune operation for optimal output. Embracing hybrid designs empowers you to balance performance and redundancy, elevating your multi-stage system’s overall effectiveness.

What Are the Maintenance Challenges Associated With Each Configuration?

You’ll face maintenance challenges with each setup. In parallel systems, corrosion issues can occur more rapidly due to increased flow rates, requiring frequent inspections. Accessibility concerns arise because components are often tightly packed, making repairs difficult. In series configurations, corrosion might develop along the entire flow path, demanding diligent monitoring. Both setups need regular checks, but the key is ensuring easy access and corrosion prevention to keep your system running smoothly.

Conclusion

When choosing between parallel and series flow configurations, consider your system’s goals and constraints. For instance, if you need to maximize efficiency, a series setup might be ideal. Conversely, if you want redundancy, parallel flows work better. Imagine a chemical plant that switches between configurations based on demand, optimizing output and safety. By understanding these options, you can make smarter choices that enhance performance and meet your specific needs more effectively.