Finding the balance between flow rate and filtration efficiency is key to optimizing your water system. A higher flow rate offers quick results but increases pressure drops and wear on filters, leading to frequent replacements. Slower flow improves contaminant removal and extends filter life, but takes more time. Adjusting and monitoring these factors helps you tailor your setup for better performance and longevity. Keep exploring this relationship to refine your system and achieve the best results.

Key Takeaways

- Increasing flow rate enhances filtration speed but raises pressure drop, risking filter clogging and higher maintenance needs.

- Higher filtration efficiency improves contaminant removal but often reduces flow rate, extending processing time.

- Balancing flow and filtration involves monitoring pressure drops to optimize filter lifespan and system performance.

- Adjusting flow rate or media can improve efficiency while minimizing wear and operational costs.

- Understanding the trade-offs helps select the right balance for specific water processing volume and quality requirements.

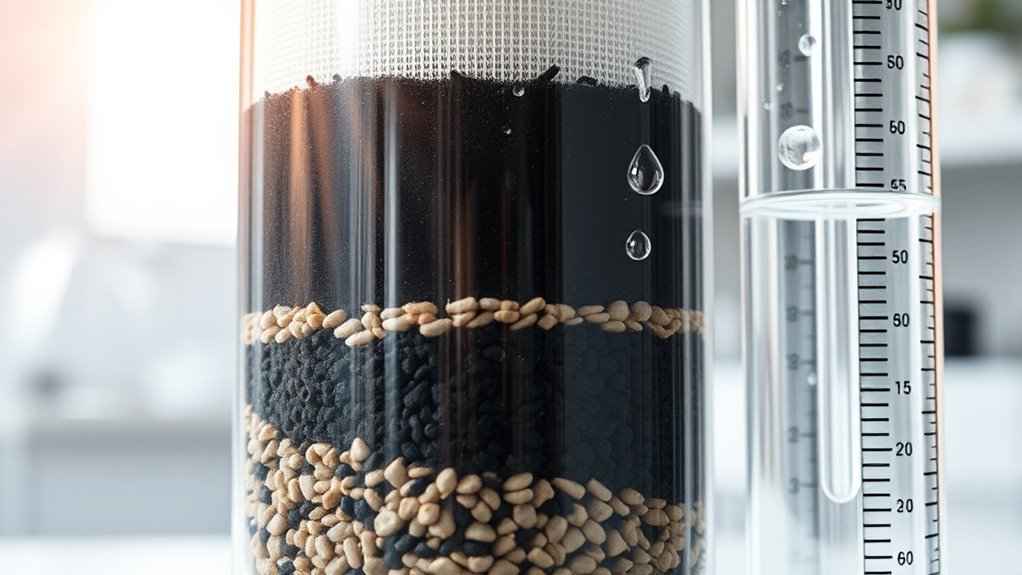

When choosing a filtration system, understanding the balance between flow rate and filtration efficiency is essential. These two factors directly impact how well your system performs and how long it lasts. A higher flow rate means water moves quickly through the filter, providing rapid filtration, which is appealing for quick results. However, pushing water through too fast can lead to increased pressure drop across the filter. This pressure drop, or resistance, can cause the system to work harder, potentially reducing the filter’s lifespan. If the pressure drop becomes too high, it may indicate that the filter is becoming clogged or that the system is operating at an unsustainable rate, leading to more frequent replacements and higher maintenance costs.

On the other hand, prioritizing filtration efficiency often involves slower flow rates. When water moves more slowly, the filter has more contact time with contaminants, resulting in better removal of impurities and a cleaner output. But this increased filtration quality can come at the expense of flow rate, making the process less efficient for applications that demand quick results. If your goal is to achieve a high filtration efficiency, you need to be prepared for potential trade-offs, including a longer filtration cycle and possibly more frequent filter changes. Over time, this can influence the overall cost-effectiveness of your system, especially if the filter’s lifespan is compromised by excessive pressure drops or clogging.

Finding the right balance means understanding your specific needs. If you require fast filtration for large volumes, you might accept a slightly higher pressure drop, knowing that it could shorten the filter’s lifespan. Conversely, if your priority is maintaining high-quality filtration over an extended period, you may choose a system with a slower flow rate, even if it takes longer to process water. Regularly monitoring pressure drop can help you gauge when to replace or clean your filter before performance declines sharply. Adjustments to flow rate or filter media can optimize both efficiency and longevity, ensuring your system operates smoothly without unnecessary wear. Additionally, understanding the contrast ratio of a projector can help you appreciate how dark scenes will appear, which is crucial for creating an immersive home cinema experience.

Ultimately, balancing flow rate and filtration efficiency involves considering how much water you need to process, the quality of filtration required, and the maintenance costs you’re willing to incur. By paying attention to pressure drops and understanding how they relate to filter lifespan, you can make more informed decisions that keep your filtration system running effectively and efficiently for longer periods.

Frequently Asked Questions

How Does Particle Size Affect Filtration Efficiency?

Particle size directly impacts filtration efficiency because smaller particles can pass through filter pores more easily, increasing the risk of particle breakthrough. If the pore size is larger than the particles, you’ll see reduced efficiency. To improve filtration, you need a filter with smaller pore sizes that trap even tiny particles, but keep in mind, this may lower flow rate. Striking the right balance prevents breakthrough while maintaining adequate flow.

Can Increasing Flow Rate Improve Filtration Performance?

Ever wondered if cranking up the flow rate improves filtration? Increasing flow rate adjustments can boost performance temporarily, but it also introduces filtration trade-offs. Faster flow might push more particles through, reducing efficiency. So, while a higher flow rate can seem beneficial, it’s crucial to find a balance—optimizing flow without compromising filtration effectiveness. Adjust carefully to ensure you maintain the best filtration performance for your needs.

What Materials Best Balance Flow Rate and Filtration?

You should choose filter materials like activated carbon, microfiber, or pleated HEPA filters for ideal flow rate and filtration balance. These materials allow you to maximize flow rate without sacrificing filtration efficiency. Focus on filter material selection and flow rate optimization to achieve the best performance. By carefully balancing these factors, you ensure your system filters effectively while maintaining a healthy, efficient airflow.

How Do Temperature and Pressure Impact Filtration Effectiveness?

Temperature and pressure critically impact filtration effectiveness. As temperature rises, thermal expansion can cause filter materials to expand, potentially increasing pore size and decreasing efficiency. Higher temperatures also reduce viscosity, improving flow but risking a pressure drop that can hinder filtration. Conversely, increased pressure enhances filtration but may cause thermal stresses or damage. Maintaining ideal temperature and pressure ensures a balance, maximizing filtration efficiency while preventing issues like thermal expansion and pressure drops.

Are There Industry Standards for Optimal Flow and Filtration Balance?

Yes, industry standards guide you in balancing flow rate and filtration efficiency. You should follow filtration standards and industry guidelines that specify ideal flow rates for different applications, ensuring you don’t compromise filtration quality. These standards help you maintain equipment performance and safety, while also maximizing filtration efficiency. Regularly consult relevant standards to adjust your filtration systems accordingly, achieving the right balance for your specific needs.

Conclusion

Just like Icarus balancing flight and caution, you must find harmony between flow rate and filtration efficiency. Pushing for higher flow might let more air through, but it could compromise filtration. Conversely, aiming for perfect filtration can slow airflow, making breathing harder. Striking that balance ensures your mask or filter works like a well-tuned chariot—efficient yet comfortable. Remember, it’s about maneuvering the tightrope between protection and breathability, just like the hero’s journey through the skies.