A salt bridge connects two parts of an electrochemical system, allowing ions to flow and complete the circuit while preventing the solutions from mixing directly. Mush fixes are used in electronics to protect components from heat, stress, and corrosion, ensuring stable signals and extending device life. Together, these solutions help keep devices working smoothly by maintaining proper connections and safeguarding parts. Keep exploring to discover how to apply them properly and safely.

Key Takeaways

- Salt bridges connect two solutions in an electrochemical cell to allow ion flow without mixing, maintaining electrical balance.

- Mush fixes are materials used to protect electronic parts from heat, shocks, and moisture, ensuring device durability.

- Salt bridges prevent charge buildup and corrosion in batteries and electrochemical experiments.

- Mush fixes fill gaps, stabilize connections, and protect components from mechanical and environmental damage.

- Proper application and safety precautions are essential for effective use of both salt bridges and mush fixes.

What Is a Salt Bridge and How Does It Work?

Have you ever wondered how two separate solutions in an electrochemical cell stay connected without mixing? It’s all thanks to the salt bridge. The salt bridge allows electrolyte conduction, enabling ions to transfer between the two solutions. This transfer maintains electrical neutrality, preventing charge buildup that would stop the reaction. Typically, the salt bridge is a tube filled with a gel or solution containing inert ions, like potassium chloride or sodium sulfate. These ions move through the bridge, balancing the flow of electrons in the external circuit. By facilitating ion transfer, the salt bridge completes the electrical circuit, allowing the electrochemical reaction to continue smoothly. Without it, the solutions would quickly become unbalanced, and the cell would stop producing electricity. Understanding electrochemical principles helps clarify how these connections sustain ongoing reactions.

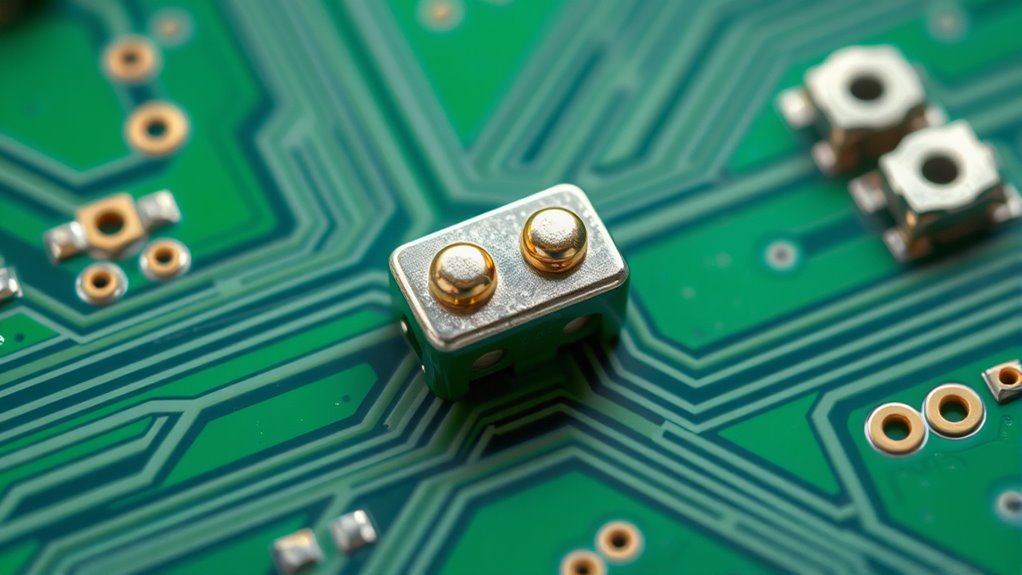

The Purpose of Mush Fixes in Electronics

Mush fixes help safeguard your electronics from component damage caused by heat or electrical stress. They also keep signals stable, preventing interruptions or noise. Ultimately, these fixes extend your device’s lifespan and ensure reliable performance. Implementing AI-driven innovations can further optimize device stability and efficiency.

Prevents Component Damage

When electronic components experience thermal expansion and contraction, stress can build up at critical joints, risking damage or failure. Mush fixes help absorb these stresses, preventing cracks and disconnections that could lead to malfunction. By providing a flexible buffer, they also aid in corrosion prevention, stopping moisture from reaching vulnerable areas and causing rust or corrosion-related failures. This ensures component protection over time, especially in environments with temperature fluctuations. Without mush fixes, repeated thermal movement can weaken solder joints and delicate connections, increasing the risk of permanent damage. In short, mush fixes act as a safeguard, reducing mechanical stress and shielding components from deterioration, ultimately extending the lifespan and reliability of your electronic devices.

Ensures Signal Stability

By absorbing mechanical stresses caused by thermal expansion and contraction, mush fixes help maintain the integrity of electronic connections. This stability guarantees that signals travel smoothly without interruptions or fluctuations. Mush fixes fill gaps and secure components, preventing micro-movements that could disrupt electrical conductivity. They also serve as a barrier against moisture and contaminants, which are common causes of corrosion prevention issues that can impair signal quality. Additionally, essential oils have properties that support material preservation by offering antimicrobial and protective effects. By keeping connections solid and protected, mush fixes help prevent signal degradation, noise, and loss of data. This reliable contact preserves the consistent flow of electrical signals, ensuring your device functions accurately and efficiently. Overall, mush fixes play a vital role in maintaining stable, high-quality signals in electronic systems.

Improves Device Longevity

Because they cushion and secure electronic components, mush fixes substantially extend the lifespan of your devices. They improve electrical conductivity by creating a stable connection, preventing issues caused by loose or corroded contacts. Mush fixes also play a crucial role in corrosion prevention, protecting sensitive parts from moisture and oxidation that can degrade performance over time. By filling gaps and absorbing vibrations, they reduce mechanical stress that could lead to cracks or damage. This stabilization helps your device maintain ideal function longer, avoiding premature failure. Additionally, color accuracy is maintained through proper component stabilization, ensuring consistent image quality in electronic devices. Overall, mush fixes help preserve the integrity of the internal circuitry, ensuring your electronics stay reliable and efficient for years to come. Their role in safeguarding components directly contributes to your device’s durability and longevity.

Common Scenarios Where Salt Bridges Are Used

Salt bridges are commonly used in battery maintenance to prevent voltage drops and improve performance. You’ll also find them essential in laboratory and testing setups where stable electrical connections matter. Understanding these scenarios helps make certain you select the right solution for reliable operation. Implementing proper salt bridge techniques can also be beneficial for maintaining consistent electrical conductivity in various applications.

Battery Maintenance Applications

In battery maintenance, salt bridges are commonly used to stabilize cells and guarantee consistent performance. They help maintain proper electrolyte levels and prevent the separation of active materials, which is essential in electrochemical chemistry. By balancing ionic charges, salt bridges reduce the risk of voltage fluctuations and improve overall efficiency. They also play a crucial role in corrosion prevention by limiting the formation of localized corrosion sites that can damage the electrodes. Properly maintained salt bridges ensure a stable environment inside the battery, extending its lifespan and reliability. In practical applications, you’ll find salt bridges used in lead-acid batteries, ensuring steady operation during repeated charge and discharge cycles. Their presence helps maintain the integrity of the electrochemical process, keeping your battery functioning at its best. Understanding appliances connection can provide insights into how different components work together to support reliable performance and maintenance.

Laboratory and Testing Uses

In laboratory and testing scenarios, salt bridges serve as essential tools for establishing stable electrical connections between half-cells in electrochemical experiments. They enable you to observe and analyze chemical reactions without interference from direct contact, guaranteeing accurate measurements. Salt bridges facilitate ion flow, maintaining electrical neutrality and preventing charge buildup. Additionally, they help prevent corrosion that could occur if the solutions were directly connected, making experiments safer and more reliable. Whether you’re studying electrode potentials, testing new materials, or simulating battery conditions, salt bridges provide a controlled environment for your tests. By preventing unwanted chemical reactions and corrosion, they guarantee your results are precise and reproducible. Proper SWIFT/BIC codes are crucial for secure financial transactions related to laboratory equipment and supplies, ensuring smooth and trustworthy procurement processes. This makes salt bridges indispensable in laboratory settings focused on electrochemical research and testing.

Understanding the Role of Mush Fixes in Repairing Devices

Mush fixes play a crucial role in restoring damaged electronic devices by filling in gaps and bonding components securely. They create a stable connection that helps maintain electrical conductivity, ensuring your device works properly. By filling voids, mush fixes also help prevent corrosion, which can occur when moisture and air reach sensitive parts. This corrosion prevention extends the device’s lifespan and maintains its performance. Mush fixes are especially useful when traditional repairs aren’t possible or practical, providing an effective, quick solution. Their adhesive properties and ability to fill irregular spaces make them ideal for securing loose parts and restoring electrical pathways. Additionally, incorporating natural materials can enhance the durability and aesthetic of repairs. Overall, mush fixes are essential for keeping devices functioning smoothly and preventing further damage.

How to Identify When a Salt Bridge or Mush Fix Is Needed

Recognizing when a salt bridge or mush fix is needed is vital for maintaining your device’s functionality. If you notice signs of corrosion, such as rusting or pitting, it indicates that contact stabilization has been compromised, and a salt bridge might be necessary. Additionally, if your device shows inconsistent performance or fluctuating readings, it suggests electrical contact issues that a salt bridge can resolve. Lack of proper corrosion prevention can accelerate damage, making these fixes essential. Regular inspection for visible corrosion or irregular behavior helps you identify when these repairs are needed. Acting promptly ensures your device maintains stable connections and peak performance, preventing further deterioration. Being aware of electrical contacts and their proper functioning is crucial for ensuring your equipment operates reliably and efficiently. Staying alert to these indicators keeps your equipment functioning smoothly and extends its lifespan.

Step-by-Step Guide to Applying a Salt Bridge

Applying a salt bridge correctly is essential for restoring proper electrical contact between components. First, gather your materials: a salt solution, a porous material like sponge or cotton, and clean tools. Dampen the sponge or cotton with the salt solution, ensuring it’s soaked but not dripping. Place it carefully between the corroded contacts, making sure it touches both surfaces evenly. Use the table below to imagine the process:

| Contact Surface | Salt Bridge Material |

|---|---|

| Corroded area | Salt-soaked sponge |

| Metal contact | Salt-soaked sponge |

| Between contacts | Salt bridge layer |

| Electrical contact | Restored connection |

This method promotes electrical repair and helps prevent future corrosion, maintaining device performance and longevity.

Potential Risks and Precautions When Using Mush Fixes

Although mush fixes can effectively restore connections, they also pose certain risks if not used carefully. You need to prioritize electrical safety to prevent shocks or short circuits. Chemical hazards are another concern, as some ingredients may be toxic or corrosive. To stay safe, consider these precautions:

- Always wear protective gloves and goggles when handling mush fixes.

- Work in a well-ventilated area to avoid inhaling fumes.

- Follow manufacturer instructions precisely to prevent chemical mishaps.

- Keep the work area free of clutter to avoid accidental contact or spills.

Being cautious minimizes risks and ensures your project stays safe and successful. Proper handling and awareness help ensure your safety while achieving effective repairs. Additionally, understanding the filter replacement process is crucial for maintaining the air purifier’s efficiency and longevity.

Frequently Asked Questions

Can Salt Bridges Be Reused After Fixing a Device?

Yes, you can reuse salt bridges after fixing a device, but reusability concerns depend on salt bridge longevity and how well it was maintained during use. Over time, salt bridges can degrade or become contaminated, reducing their effectiveness. If they’re still intact and clean, reusing them is possible. However, always inspect for cracks, corrosion, or buildup to ensure they’ll continue to perform properly in the repaired device.

Are There Alternative Methods to Salt Bridges and Mush Fixes?

Sure, there are chemical alternatives to salt bridges and mush fixes, but don’t expect them to turn your repair into a long-lasting fairy tale. You could try epoxy resins or conductive adhesives—they might boost repair longevity, but they’re no magic bullets. Still, if you’re after a quick fix that’s less messy, these options can work, though they might not hold up as well over time.

How Long Do Salt Bridges and Mush Fixes Typically Last?

Salt bridges and mush fixes usually last between 6 months to a year, but their durability depends on environmental factors like humidity, temperature, and exposure to moisture. If conditions are ideal, they might last longer, but in harsher environments, they tend to degrade sooner. To guarantee peak performance, monitor their condition regularly and replace them as needed, especially if you notice signs of deterioration or failure.

Do Salt Bridges Cause Any Long-Term Damage to Electronics?

Think of salt bridges as double-edged swords—they can cause corrosion risks if not used properly. If you’re concerned about long-term damage, it’s vital to take into account material compatibility; incompatible materials can accelerate corrosion. While salt bridges don’t always cause immediate harm, over time, they may lead to corrosion issues that damage your electronics. Regular inspection and proper maintenance help prevent long-term damage, ensuring your devices stay safe and functional.

Are Salt Bridges Suitable for All Types of Electronic Repairs?

Salt bridges aren’t suitable for all types of electronic repairs because device compatibility varies. You should consider repair limitations, as salt bridges work best for specific issues like corrosion or minor conductivity problems. Using them on incompatible devices can cause further damage or fail to fix the problem. Always evaluate your device’s needs and consult a professional if you’re unsure, ensuring the repair method matches the device requirements.

Conclusion

Understanding salt bridges and mush fixes helps you troubleshoot, repair, and prevent electronic issues with confidence. Recognize the signs, apply the right fix, and take precautions to protect your devices. By knowing when and how to use these solutions, you guarantee longevity, safety, and peak performance. Stay informed, stay prepared, and keep your electronics running smoothly—because proper maintenance and timely repairs make all the difference.