To guarantee your pre-filter housing and cartridges work effectively, match the cartridge material to your water source—whether it’s well, city, or surface water. Keep an eye on flow rates and pressure drops to prevent system damage or inefficiency. Regularly inspect and replace cartridges before bypass occurs, and choose the right housing size for your needs to avoid issues. Understanding temperature and chemical compatibility extends equipment life. Stick with this advice, and you’ll open better water quality and system longevity.

Key Takeaways

- Match cartridge material to your water source for optimal contaminant removal.

- Monitor flow rate and pressure drop to prevent system damage and ensure effective filtration.

- Regularly inspect and replace cartridges to avoid bypass and maintain water quality.

- Choose the correct housing size based on your flow needs and water volume.

- Ensure material compatibility with temperature and chemicals to prevent leaks and system failure.

Match the Cartridge Material to Your Water Source

Choosing the right cartridge material depends on the specific contaminants and conditions of your water source. Your water source, whether well water, city supply, or surface water, introduces different impurities that require tailored filtration. For example, if your water contains sediment or particulates, a cartridge made of polypropylene or sediment filters works best. For organic compounds or chlorine, activated carbon cartridges are effective. If you’re dealing with heavy metals, look for cartridges with specialized media like ion exchange resins. Matching the cartridge material to your water source ensures ideal filtration and prevents clogging or ineffective purification. Understanding your water’s unique characteristics helps you select the appropriate cartridge material, making your pre-filter system more efficient and prolonging its lifespan. Additionally, vertical storage solutions can help organize your filtration components and supplies, ensuring easy access and maintenance.

Consider Flow Rate and Pressure Drop Carefully

Understanding flow rate and pressure drop is essential because they directly affect your pre-filter system’s performance and longevity. Proper flow rate maximization ensures your filter doesn’t become overwhelmed or underutilized, maintaining effective filtration. Too high a flow rate can cause excessive pressure drop, reducing system efficiency and risking damage. Conversely, a flow that’s too low might lead to inadequate filtration and longer processing times. Managing pressure drop involves selecting the right filter cartridges and ensuring they’re not clogged or undersized, which can cause unnecessary strain on your system. Additionally, filter maintenance plays a crucial role in sustaining optimal flow and pressure conditions. By carefully considering flow rate and pressure drop, you can extend filter life, improve water quality, and prevent costly repairs. Always evaluate your water flow needs and monitor pressure regularly for ideal performance.

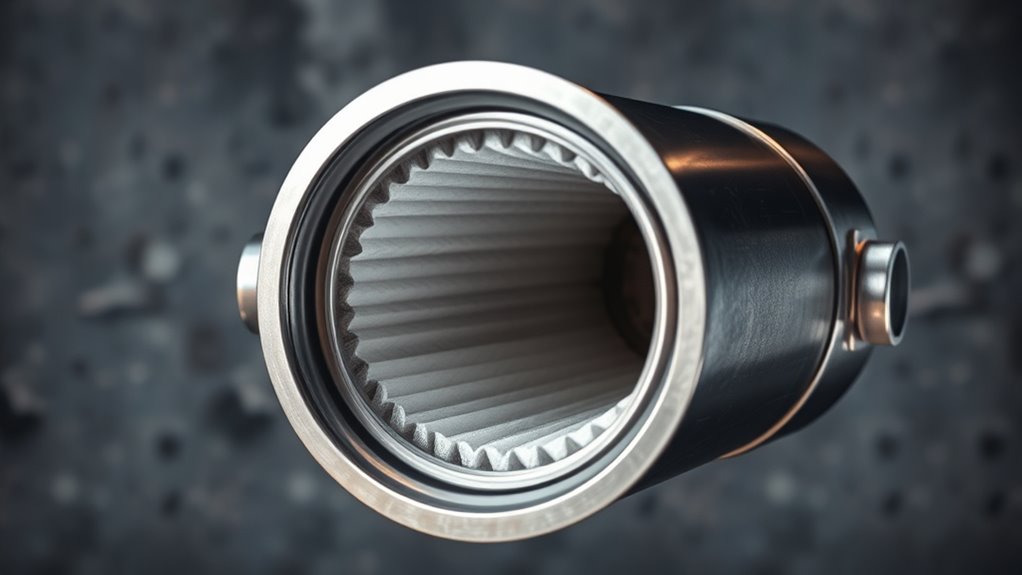

Regularly Inspect and Replace Cartridges to Prevent Bypassing

Regularly inspecting and replacing cartridges is essential to prevent bypassing and maintain filtration efficiency. Over time, the cartridge lifespan decreases as dirt and debris clog the media, reducing its ability to filter properly. Sticking to a consistent replacement schedule ensures you catch these signs early, preventing contaminated water from bypassing the filter. Ignoring this maintenance can lead to compromised water quality and increased system strain. Keep a record of your cartridge’s age and condition, and don’t wait for visible signs of dirt or pressure drops. Regular inspections allow you to identify wear before bypass occurs, ensuring your filtration system works effectively. Properly timed replacements protect your system’s integrity and prolong its lifespan, saving you money and ensuring consistent water quality. Additionally, understanding the importance of filter maintenance can help maintain optimal performance and prevent costly repairs.

Use the Correct Housing Size for Your Application

Using the correct housing size for your application is vital to guarantee your filtration system performs effectively. Selecting the right housing dimensions ensures proper flow rates and adequate filtration capacity. An undersized housing can cause pressure drops and bypassed contaminants, while an oversized one may lead to unnecessary costs and complexity. To choose correctly, measure your system’s flow rate and water volume needs carefully. Follow installation tips such as verifying compatibility with your cartridge type and ensuring secure fittings. Always match the housing size to your specific application, whether for residential, commercial, or industrial use. Proper sizing minimizes maintenance issues and optimizes filtration efficiency, helping your system operate smoothly and reliably over time. Additionally, understanding bedroom design principles can help you create a comfortable space that complements your filtration setup and overall environment.

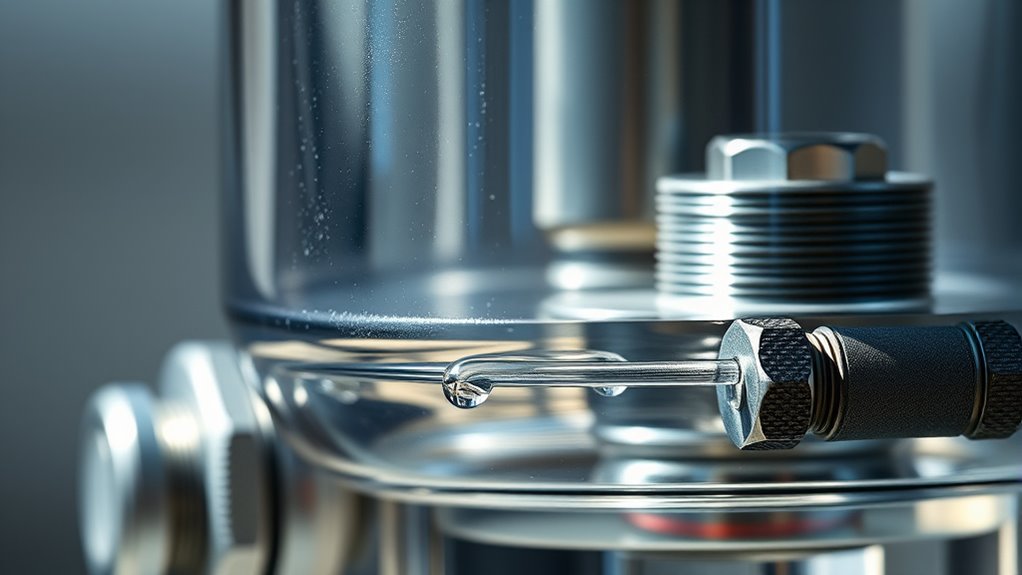

Understand the Impact of Temperature and Chemical Compatibility

Temperature fluctuations and chemical exposure can profoundly affect the performance and longevity of your filter housings and cartridges. Temperature effects influence material strength and seal integrity, so selecting a housing compatible with your operating temperature range is vital. Extreme heat can cause warping or degradation, reducing filtration efficiency. Chemical resistance is equally important; exposure to incompatible chemicals can weaken materials, leading to leaks or failures. Always check the chemical compatibility of your filter housing and cartridge with the substances they’ll contact regularly. Failing to take these factors into account may result in premature replacements, increased maintenance costs, or contaminated output. By understanding how temperature effects and chemical resistance impact your filtration system, you guarantee reliable operation and extend the lifespan of your equipment.

Frequently Asked Questions

Can Pre Filter Housings Be Reused After Cartridge Replacement?

Yes, you can reuse pre filter housings after changing the cartridge, but it depends on the cartridge lifespan and housing compatibility. Inspect the housing for cracks or wear, and verify it fits the new cartridge properly. Regularly cleaning the housing extends its lifespan, making it reusable. Just make sure the new cartridge matches the housing’s specifications and that it’s still in good condition for maximum filtration.

How Do I Dispose of Used Cartridges Safely?

You should dispose of used cartridges safely by following proper disposal methods, which often involve recycling or designated waste facilities. First, remove the cartridge carefully, avoiding contact with contaminants. Then, consider cartridge cleaning if applicable, but if not, use approved disposal methods like recycling programs or hazardous waste facilities. Always wear gloves and follow your local regulations to guarantee environmental safety and personal protection.

Are There Eco-Friendly Cartridge Options Available?

Yes, eco-friendly cartridge options are available. You can choose cartridges made from biodegradable materials that break down naturally, reducing environmental impact. Look for eco-conscious brands committed to sustainability, offering cartridges designed for easy recycling or composting. Switching to these options helps you minimize waste and supports environmentally responsible practices. Always check product details to verify the cartridges align with your eco-friendly goals and are compatible with your filtration system.

What Are Signs of a Failing Pre Filter Housing?

Did you know that over 60% of pre filter failures are caused by housing corrosion? If you notice cracks, leaks, or rust on your pre filter housing, it’s a clear sign it’s failing. A reduced pre filter lifespan often correlates with these issues, so inspect your housing regularly. Addressing corrosion early can prevent contamination and costly replacements, ensuring your filtration system keeps working efficiently.

How Do I Upgrade My Housing for Higher Capacity Needs?

To upgrade your housing for higher capacity needs, choose a model with durable housing materials like stainless steel or high-grade plastic that withstands increased flow. Guarantee it’s compatible with your existing system, and follow installation tips such as proper sealing and secure fittings to prevent leaks. Consider a larger housing size or a multi-cartridge setup for more capacity, and double-check manufacturer guidelines for smooth integration and ideal performance.

Conclusion

By following these five rules, you’ll guarantee your pre-filter housing and cartridges perform at their best. Don’t you want clean, safe water without surprises or costly repairs? When you match materials, monitor flow rates, inspect regularly, choose the right size, and consider temperature and chemicals, you set yourself up for success. Take these steps seriously, and you’ll enjoy reliable filtration—because your water deserves nothing less. Are you ready to upgrade your system today?