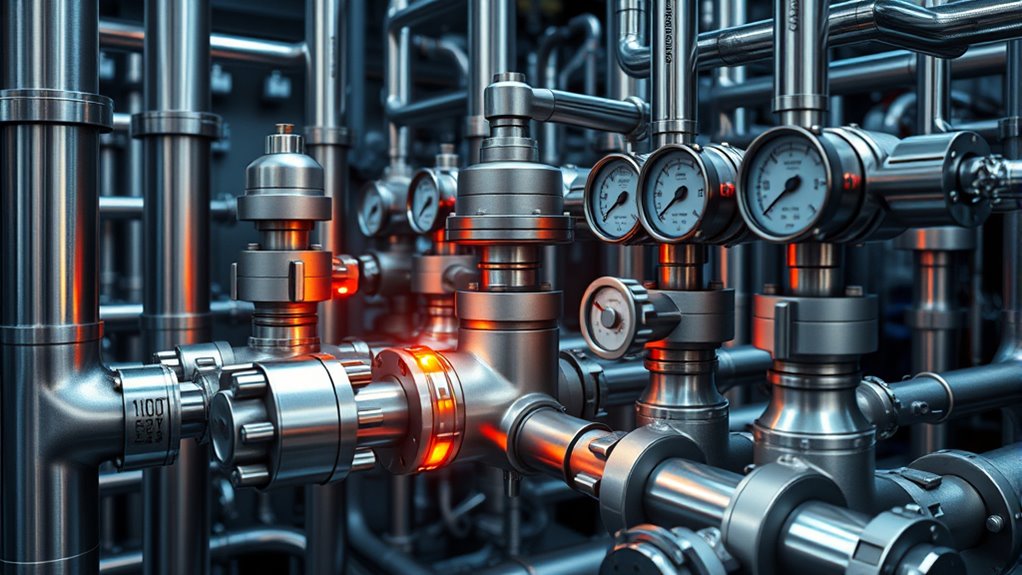

To create advanced valving layouts that make sense, you need to focus on precise calculations of flow rates, pressure drops, and system dynamics. Proper pipe sizing, selecting the right valve types, and sizing valves correctly help prevent issues like cavitation and pressure losses. Analyzing system pressure recovery and planning for future expansion are also critical. Mastering these calculations guarantees your system runs efficiently and safely—continue exploring to discover how these principles come together in practical designs.

Key Takeaways

- Properly size valves based on flow requirements and pressure drops to maintain system efficiency and prevent cavitation.

- Strategically position isolation and control valves near equipment for quick shutdowns and precise regulation.

- Incorporate pressure loss calculations from fittings, valves, and pipe segments to optimize flow and reduce turbulence.

- Design valving layouts that minimize pressure transient effects during startup, shutdown, or sudden operational changes.

- Ensure compatibility of valve materials, actuators, and control protocols for reliable, future-proof system integration.

Understanding Flow Rates and Pressure Drops

Understanding flow rates and pressure drops is essential for designing efficient valve systems. When fluid moves through pipes, flow turbulence can cause unpredictable pressure fluctuations, impacting system stability. High flow rates increase turbulence, leading to pressure drops that can reduce efficiency or cause damage. Recognizing how pressure fluctuations occur helps you anticipate potential issues and choose the right valve sizes and configurations. Smooth, steady flow minimizes turbulence and pressure fluctuations, ensuring consistent operation. Monitoring these factors allows you to optimize system performance, prevent unnecessary wear, and maintain safety standards. Paying close attention to battery technologies and pressure drops enables better system integration and longevity. By paying close attention to flow rates and pressure drops, you can design valve layouts that handle varying conditions without compromising efficiency or reliability.

Calculating Pipe Diameter for Optimal Flow

How do you determine the right pipe diameter to guarantee ideal flow? Start by considering your system’s flow requirements and pressure drop limitations. The pipe material influences flow capacity; for example, smooth materials like PVC reduce friction losses, allowing for smaller diameters. Accurate calculations involve applying the Darcy-Weisbach or Hazen-Williams equations, factoring in flow rate, pipe length, and roughness. Proper installation techniques also matter—ensuring pipes are aligned and supported minimizes turbulence and flow restrictions. If the diameter is too small, flow resistance increases, risking pressure loss and inefficiency. Conversely, oversized pipes add unnecessary costs. Additionally, understanding system flow dynamics helps in selecting the appropriate pipe size. By carefully balancing these factors, you select a pipe diameter that optimizes flow, reduces energy consumption, and guarantees system longevity.

Selecting the Right Valve Types for Your System

Choosing the right valve types depends on understanding their compatibility with your system’s materials and operating conditions. You need to take into account application-specific factors like pressure, flow rate, and media type to guarantee optimal performance. Making informed selections now will help you avoid issues and improve efficiency down the line. Additionally, understanding store hours can be crucial when planning on-site inspections or parts replacements to ensure timely maintenance.

Valve Compatibility Factors

Selecting the right valve type for your system depends on several key compatibility factors. You need to take into account material compatibility to ensure the valve works with your fluids and environment. Installation techniques also matter—some valves require specific mounting or connection methods. Other factors include pressure and temperature ratings, actuator compatibility, and flow control needs. Incorporating somatic awareness into your maintenance practices can help you better recognize early signs of valve issues before they lead to failures. Keep these in mind:

- Compatibility of valve materials with your media

- Proper sealing for leak prevention

- Suitability of installation techniques

- Pressure and temperature limits

- Ease of maintenance and repair

Addressing these factors helps prevent failures, extends valve lifespan, and maintains system efficiency. By matching valve features to your system’s demands, you ensure reliable performance from the start.

Application-Specific Valve Choice

Have you ever wondered why certain valves perform better in specific applications? The key lies in selecting the right valve type based on material compatibility and installation techniques. For instance, if your system handles corrosive fluids, choose valves made from compatible materials like stainless steel or plastic to prevent degradation. Proper installation guarantees the valve functions reliably and minimizes leaks. Consider factors like pressure ratings and flow requirements to match your system’s needs. Different applications demand different valve designs—ball, globe, or butterfly valves—each suited for specific tasks. By understanding material compatibility and applying correct installation techniques, you can optimize performance, extend valve lifespan, and avoid costly failures. Incorporating mindfulness into your planning process can help you make more thoughtful and effective decisions. Choosing the right valve isn’t just about function; it’s about ensuring safety, efficiency, and long-term system integrity.

Determining Valve Sizing to Prevent Cavitation

How can you guarantee your valve is properly sized to prevent cavitation? Proper valve sizing is vital for cavitation prevention, ensuring the flow velocity doesn’t drop pressure below vapor pressure. To achieve this, consider these key points:

Proper valve sizing prevents cavitation by maintaining appropriate flow velocities and pressures.

- Calculate flow rate requirements accurately

- Use valve flow coefficients (Cv) matching system demands

- Monitor upstream and downstream pressures closely

- Select a valve type designed for high-pressure drops

- Ensure the valve operates within its ideal range

- Be aware of headphones and their compatibility considerations when integrating with control systems to avoid unintended interference or malfunctions.

Analyzing System Pressure Losses and Recovery

To effectively prevent cavitation, it’s important to understand how pressure losses within the system impact overall performance. Pressure transients can cause sudden drops in pressure, leading to flow turbulence and unstable conditions. These transient pressure changes may result from valve closures, pump startups, or system switching, which disrupt smooth flow. Analyzing pressure losses involves examining friction, fittings, and valve impacts on flow velocity. Recognizing areas where flow turbulence peaks helps identify potential trouble spots. Recovery occurs when the system stabilizes, and pressure is restored after transient events. By monitoring pressure transients and understanding their effects on flow turbulence, you can optimize valving layouts to minimize pressure drops and ensure efficient, safe operation. This analysis is crucial for reliable system performance, especially considering the personality traits of operators that influence system management.

Evaluating the Impact of Valving Layout on System Safety

You need to ensure how your valving layout guarantees proper isolation to prevent cross-contamination or leaks. A well-designed system reduces the chance of unexpected failures that could compromise safety. Ultimately, evaluating these aspects helps you create a safer, more reliable system. Paying attention to system integrity during design and maintenance further enhances safety and operational efficiency.

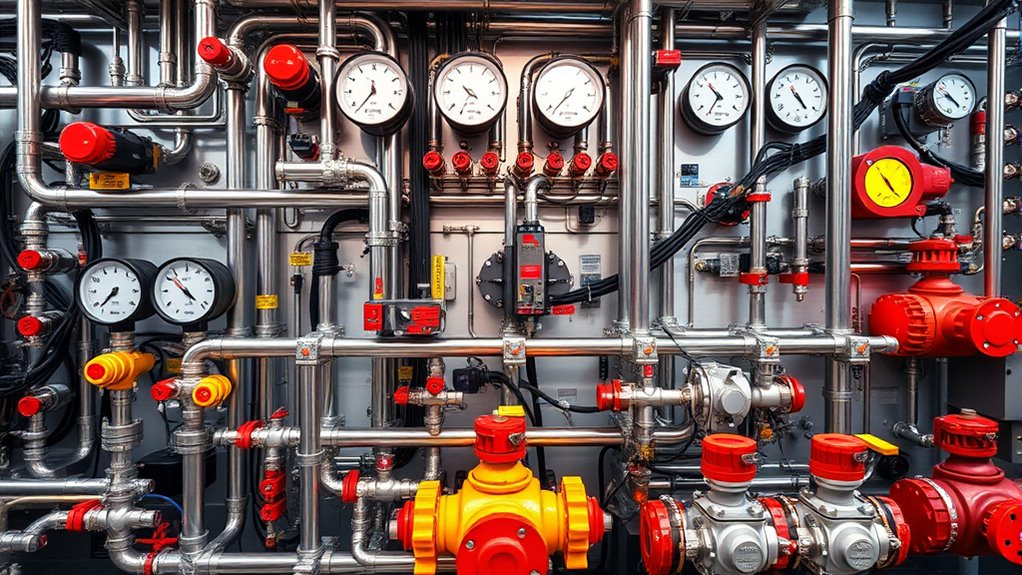

Ensuring Proper Isolation

Have you ever contemplated how the layout of valves directly influences the safety and reliability of a system? Proper isolation depends on strategic valve placement and design. Effective isolation ensures maintenance can be performed safely without affecting the entire system. To achieve this, you need to focus on reliable installation techniques and regular valve maintenance. Poor valving layout can lead to accidental leaks or failures, jeopardizing safety. Here are key points to think about:

- Position isolation valves close to equipment for quick shutdowns

- Use redundant valves for critical sections

- Ensure clear labeling for easy identification

- Follow proper installation techniques to prevent leaks

- Schedule routine valve maintenance to maintain integrity

- Incorporate system safety protocols to further enhance protection

Implementing these measures guarantees proper isolation, safeguarding personnel and equipment.

Preventing Unexpected Failures

A well-designed valving layout plays a vital role in preventing unexpected system failures. Choosing the right valve material ensures compatibility with the fluid and operating conditions, reducing corrosion and fatigue risks. Using appropriate installation practices, such as proper torque and secure connections, minimizes the chance of leaks or valve malfunction. Proper placement of valves allows for quick isolation during emergencies, preventing damage and ensuring safety. Regular inspection and maintenance are essential to detect early signs of wear or material degradation. Additionally, verifying that valves are rated for system pressure and temperature prevents overpressure incidents. Incorporating specialized valve materials designed for specific applications can further enhance system durability. By prioritizing suitable valve materials and meticulous installation practices, you greatly enhance system reliability, safeguard personnel, and avoid costly failures.

Designing for Future Expansion and Scalability

To guarantee your valving layout can accommodate future needs, it’s vital to incorporate scalability considerations from the outset. Planning ahead ensures you won’t have to overhaul your system later. Focus on selecting materials compatible with potential added fluids or chemicals, preventing costly replacements. Keep maintenance considerations in mind—design for easy access and modular expansion. Consider adding extra ports or outlets now to simplify future configurations. Use flexible piping and valve arrangements that can adapt as your system grows. Think about your control system’s capacity to handle increased complexity. Always document your existing setup so future adjustments remain straightforward. This proactive approach saves time, reduces costs, and keeps your system ready for expansion without sacrificing reliability.

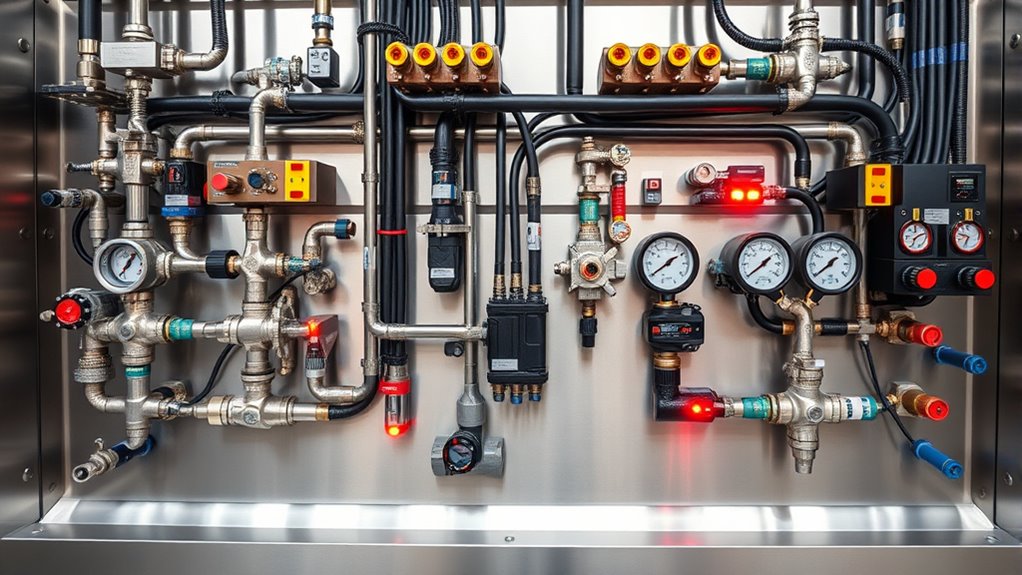

Integrating Control Valves With Automation Systems

Integrating control valves with automation systems enhances precision and efficiency in managing process flows. To achieve this, proper sensor calibration is essential; accurate sensors guarantee reliable feedback for the control system, leading to better process control. When selecting actuators, consider responsiveness and compatibility with your automation platform to optimize performance. Proper integration allows real-time adjustments, reducing manual intervention and increasing system reliability. You’ll need to guarantee communication protocols align between the control system and the valve components, facilitating seamless data exchange. By focusing on sensor calibration and actuator selection, you guarantee your control valves operate precisely within your automated setup. This integration results in improved process stability, energy savings, and easier maintenance, making your valving layout both advanced and dependable.

Ensuring Proper Venting and Drainage in Valving Arrangements

Proper venting and drainage are critical for maintaining safe and efficient valving arrangements, especially in systems handling gases or liquids that can generate pressure buildup or trap fluids. Without proper venting strategies, pressure can cause system failure or leaks, while poor drainage considerations can lead to fluid accumulation and damage. To optimize your setup, consider:

Proper venting and drainage prevent system failure and ensure safe, efficient valving operation.

- Installing vent valves at high points for pressure release

- Using drain valves in low spots to prevent fluid pooling

- Ensuring vents are protected from debris and blockages

- Incorporating check valves to prevent backflow

- Regularly inspecting and maintaining venting and drainage components

Focusing on these aspects helps prevent pressure issues, fluid trapping, and system failures, ensuring your valving arrangements operate smoothly and safely. Proper venting strategies and drainage considerations are essential for reliable system performance.

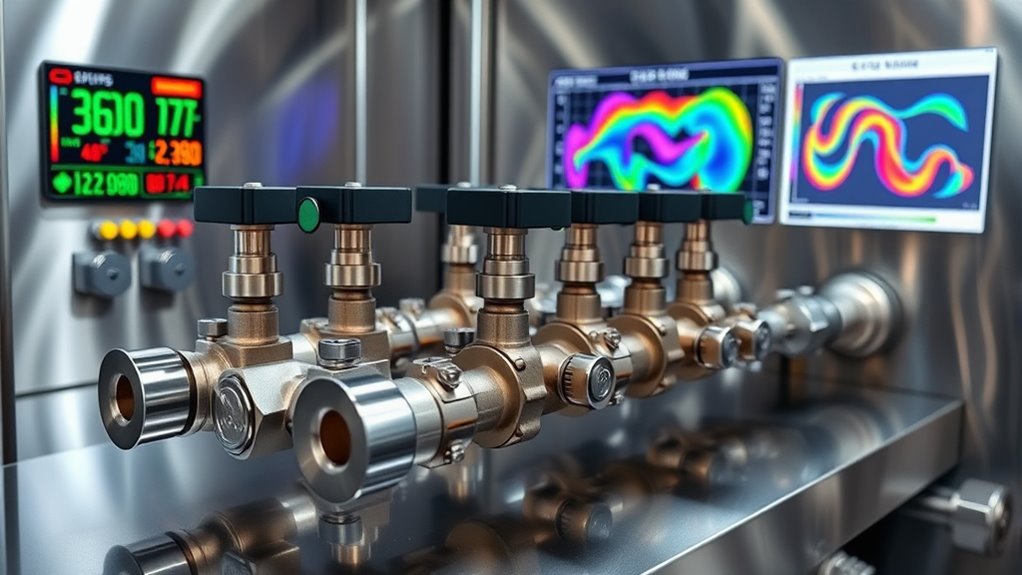

Validating Layouts Through Computational Fluid Dynamics

Validating valving layouts with computational fluid dynamics (CFD) allows you to predict how fluids will move through your system, identifying potential issues before physical implementation. By performing flow simulation, you can see how different design choices impact flow patterns, pressure drops, and turbulence. This process enables layout optimization, ensuring your valving arrangement maximizes efficiency and minimizes energy consumption. CFD helps you visualize complex flow behaviors that are difficult to anticipate through calculations alone. With accurate flow simulation data, you can refine your design, avoiding costly rework and operational inefficiencies. Validating layouts through CFD is a vital step in creating advanced, reliable valving systems that perform as intended under real-world conditions.

Frequently Asked Questions

How Do Temperature Variations Affect Valve Selection and Layout?

Temperature variations considerably impact valve selection and layout because thermal expansion causes pipe materials to expand or contract, affecting pressure differentials. You need to choose valves that accommodate these changes to prevent leaks or failures. By considering thermal expansion, you guarantee the valve can handle fluctuations smoothly, maintaining system integrity. Proper layout also accounts for movement, reducing stress and potential damage caused by temperature-driven pressure differences.

What Are the Best Practices for Maintenance Access in Complex Layouts?

Did you know that proper maintenance access can reduce valve downtime by up to 30%? To optimize, you should design layouts with clear pathways for valve calibration and leak detection tools. Guarantee easy access to critical valves, use removable panels, and incorporate sufficient space for inspection and repairs. Regularly review and update access points, and train personnel to efficiently perform maintenance, minimizing disruptions in complex systems.

How Do Material Choices Impact Valve Lifespan and Reliability?

Material choices directly impact your valve’s lifespan and reliability. Selecting materials with proper compatibility guarantees the valve withstands your specific environment, reducing wear and tear. Prioritize corrosion-resistant materials to prevent rust and degradation over time. By choosing the right materials, you minimize maintenance needs, avoid unexpected failures, and extend the valve’s operational life, making your system more dependable and cost-effective in the long run.

Can Modular Valving Layouts Simplify System Upgrades?

Yes, modular valving layouts can simplify system upgrades. They allow you to quickly replace or add components without overhauling the entire system. This flexibility supports remote monitoring and automation integration, enabling you to optimize performance and troubleshoot efficiently. With modular designs, you can adapt to future needs more easily, reducing downtime and costs while ensuring your system stays current with technological advancements.

What Safety Considerations Are Critical During System Startup?

Think of startup as walking a tightrope—you need balance and caution. You should prioritize emergency procedures and carefully conduct pressure testing to catch potential issues early. Make certain all safety valves are in place and functioning, and monitor system pressures constantly. Stay alert, and don’t rush—this way, you’ll prevent accidents and ensure a smooth, safe system startup, like a tightrope walk ending in a confident, safe landing.

Conclusion

Think of your valving layout as the heartbeat of your system—every beat must be precise to keep everything flowing smoothly. By understanding flow rates, choosing the right valves, and validating your design, you guarantee your system’s pulse stays strong and steady. When you design thoughtfully, you build a resilient network that adapts and thrives. Keep these calculations in mind, and your valving layout will beat with confidence and efficiency.