Bypass valves help control fluid flow and prevent pressure issues in your system. If they malfunction, you might notice pressure fluctuations, strange noises, or system shutdowns. Common causes include improper installation, wear, or debris buildup. Troubleshooting involves checking for leaks, verifying correct setup, and inspecting for obstructions. Regular maintenance keeps them working smoothly. Keep exploring these tips to better understand how to keep your bypass valves functioning properly and avoid problems.

Key Takeaways

- Bypass valves control fluid flow, diverting it when pressure exceeds safe levels to protect equipment.

- Signs of malfunction include leaks, noises, inconsistent pressure, and system shutdowns.

- Common problems stem from improper installation, wear, corrosion, debris, or neglecting maintenance.

- Troubleshooting involves inspecting for leaks, debris, proper installation, and testing valve operation manually.

- Regular maintenance, cleaning, lubrication, and calibration help prevent bypass valve issues and ensure smooth operation.

Understanding the Role of Bypass Valves in Your System

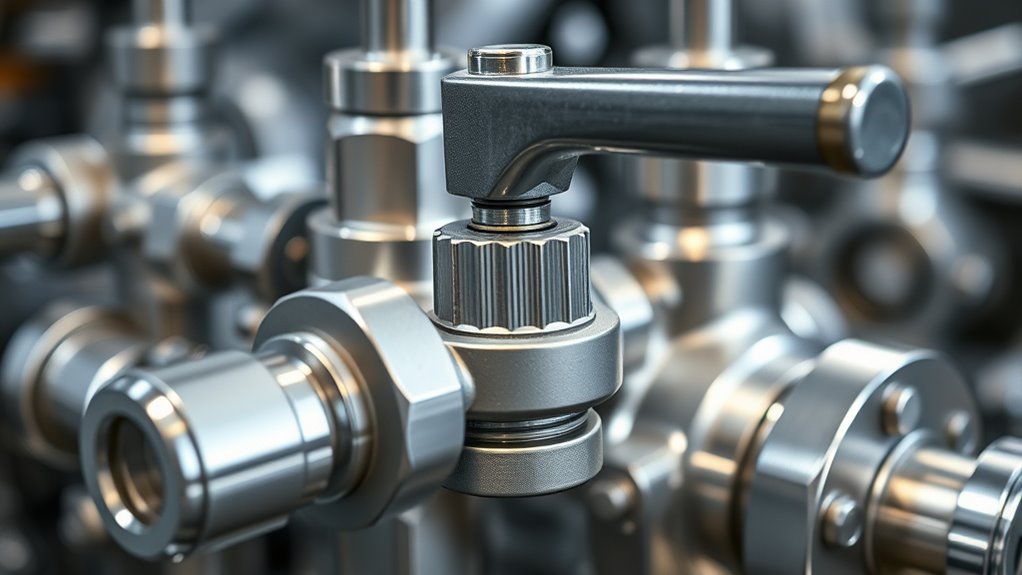

Bypass valves play a pivotal role in managing the flow within your system, allowing fluid to bypass certain components when necessary. They are essential for precise flow control, ensuring that fluid moves efficiently without overloading parts or causing pressure spikes. When the system detects pressure exceeds safe levels, the bypass valve opens to divert fluid, helping to regulate pressure and prevent damage. This regulation maintains a steady flow, optimizing performance and protecting sensitive equipment. Proper understanding of their role is key to effective system operation. Additionally, eye patches can be used as part of a maintenance routine to support overall system health and longevity.

Signs That Your Bypass Valve Might Be Malfunctioning

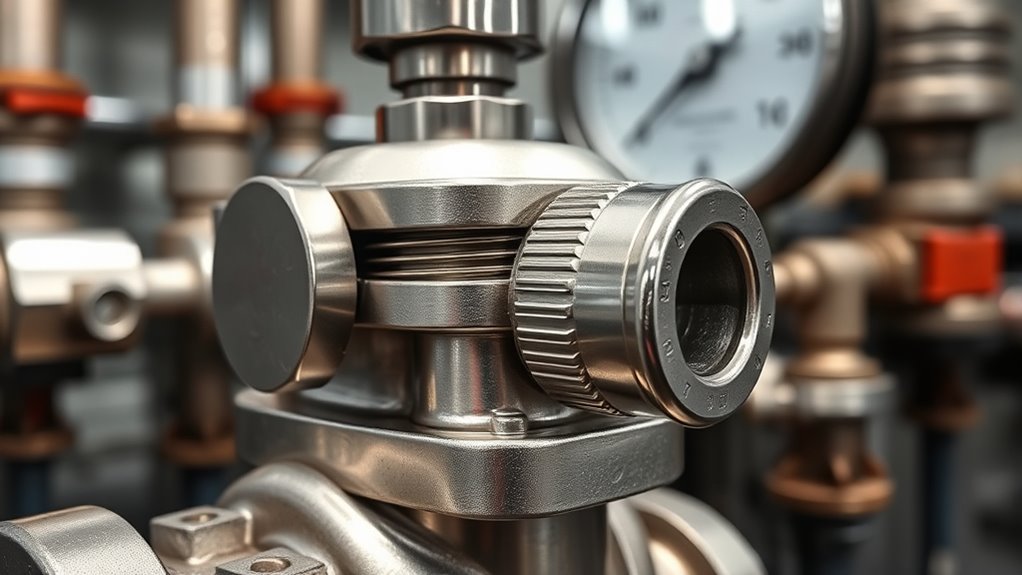

If your system isn’t operating smoothly, a malfunctioning bypass valve could be be the culprit. Look for signs like inconsistent pressure, unusual noises, or frequent system shutdowns. These issues often indicate that the valve isn’t opening or closing properly. Proper installation tips and design considerations are essential for avoiding these problems, but when issues arise, they become clear. Additionally, understanding celebrity lifestyle insights can offer interesting perspectives on how public figures manage their private spaces and routines, which can inspire maintenance and aesthetic choices for your own equipment.

Common Causes of Bypass Valve Problems

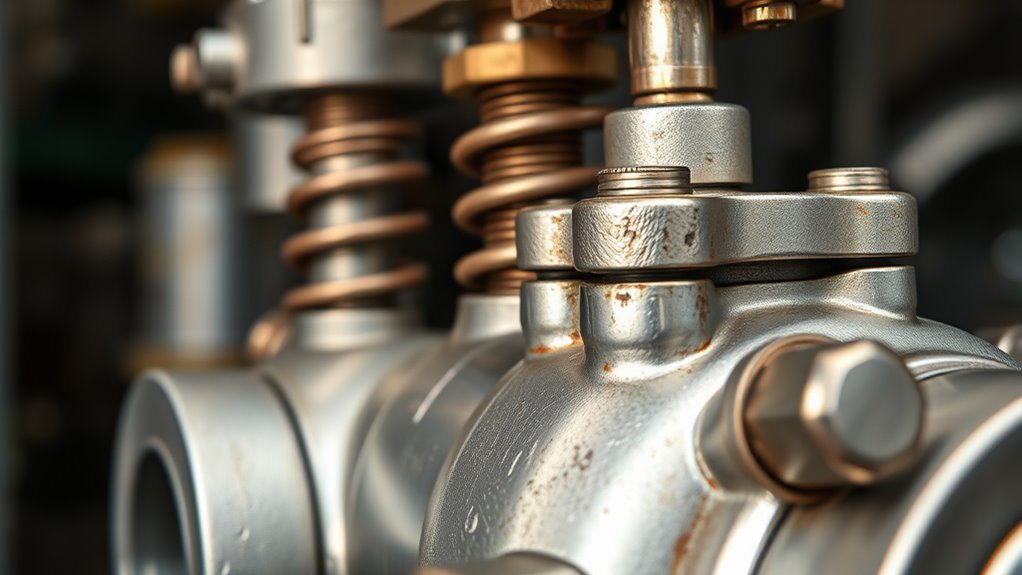

Many issues with bypass valves originate from installation mistakes, wear and tear, or manufacturing defects. Incorrect installation can cause misalignment or improper sealing, leading to malfunction. To avoid this, follow proper installation tips, ensuring the valve is mounted securely and according to the manufacturer’s instructions. Another common cause is neglecting valve specifications; using a valve with incompatible pressure ratings or size can cause leaks or failure. Over time, physical wear, corrosion, or debris buildup can also impair valve operation. Regular inspections and maintenance help catch these problems early. Additionally, awareness of AI security vulnerabilities and ensuring that control systems are protected from cyber threats can prevent malicious interference with valve operation. By paying close attention to installation details and choosing valves that match the correct specifications, you can considerably reduce the likelihood of bypass valve problems and ensure reliable performance.

Step-by-Step Troubleshooting Procedures

When troubleshooting bypass valve issues, the first step is to gather all relevant information about the problem. Check for any signs of leaks, unusual noises, or inconsistent operation. Review the installation guidelines to verify the valve was installed correctly and that all connections are secure. Confirm that the materials used are compatible with your system’s fluid type and temperature range, as incompatible materials can cause failures. Next, inspect the valve for debris or corrosion that might obstruct movement. Test the valve’s response by manually operating it if possible. Document your findings to identify patterns or recurring issues. Additionally, ensure that the materials of the valve components are suitable for the specific application, as material compatibility is crucial for proper functioning. Following these steps helps pinpoint whether the problem stems from improper installation, material incompatibility, or mechanical failure, setting a clear path for further troubleshooting.

Tips for Maintaining and Preventing Bypass Valve Issues

Regular maintenance is key to keeping bypass valves functioning properly and preventing issues before they start. Proper upkeep guarantees smooth flow regulation and reliable pressure control. To maintain your bypass valve effectively: 1. Regularly inspect for leaks or corrosion, which can disrupt flow regulation. 2. Clean or replace filters to prevent blockages that impair pressure control. 3. Lubricate moving parts to ensure smooth operation and prevent sticking. 4. Check calibration periodically to maintain accurate flow regulation and pressure settings. Additionally, understanding the role of contrast ratio in image quality can help troubleshoot visual issues with projectors, ensuring optimal performance.

Frequently Asked Questions

Can Bypass Valves Be Repaired or Do They Need Replacement?

You can often repair bypass valves if the leak is minor or due to dirt, by performing leak repair or cleaning. However, if the valve’s internal parts are damaged or calibration is off, replacement is usually necessary. Regular maintenance, including valve calibration, helps prevent issues. If repair isn’t effective, replacing the valve ensures proper operation and avoids future problems. Always assess the damage before deciding on repair or replacement.

How Do I Choose the Right Bypass Valve for My System?

Choosing the right bypass valve is like finding a needle in a haystack, but focus on your system’s needs. Consider valve materials—stainless steel or brass for durability—and follow installation guidelines carefully to make certain of proper fit and function. Match the valve size to your system’s flow rate, and check compatibility with existing components. Doing so guarantees smooth operation and prevents future headaches, making your system run like clockwork.

What Safety Precautions Should I Take During Troubleshooting?

When troubleshooting bypass valves, you should always wear personal protective equipment like gloves and safety goggles to prevent injuries. Make certain electrical safety by disconnecting power before working on the system to avoid shocks. Keep the work area dry and clear of hazards, and follow manufacturer instructions carefully. If you’re unsure, consult a professional to minimize risks. Prioritizing safety helps prevent accidents and ensures effective troubleshooting.

Are There Any Signs of Imminent Bypass Valve Failure?

Yes, there are warning signs and early indicators of imminent bypass valve failure. You might notice inconsistent system pressure, unusual noises, or frequent system shutdowns. Leaking around the valve or difficulty in opening and closing it can also signal trouble. Pay close attention to these signs, as catching problems early can prevent costly repairs and system failure. Regular inspections help guarantee your bypass valve operates smoothly and safely.

How Often Should Bypass Valves Be Inspected or Serviced?

A stitch in time saves nine, so you should inspect your bypass valves regularly. Follow the manufacturer’s recommended maintenance schedule, typically checking them every 6 to 12 months. Inspection frequency depends on your system’s usage and environment; harsher conditions may require more frequent checks. Regular maintenance helps catch issues early, ensuring smooth operation and preventing costly failures down the line. Stay proactive to keep your system running efficiently.

Conclusion

Remember, a problem shared is a problem halved, so don’t ignore signs of bypass valve issues. Regular maintenance and quick troubleshooting can save you time and money down the line. Stay proactive, stay safe, and keep your system running smoothly. As the saying goes, “An ounce of prevention is worth a pound of cure”—so stay vigilant and take care of your valves before small issues turn into big headaches.