If your pipes start banging or rattling after recent plumbing changes, it’s often caused by water hammer, loose pipes, or inadequate insulation. Water hammer happens when sudden stops in water flow create shockwaves, leading to noise. Securing pipes, adding supports, or installing water hammer arrestors can stop these noises. Pipes expanding or contracting from temperature changes or pressure fluctuations can also cause vibrations. Keep exploring for simple tips to quiet your plumbing and prevent future issues.

Key Takeaways

- Noisy pipes often result from water pressure changes, pipe movement, or air trapped inside the plumbing system.

- Common causes include rapid valve closures, loose pipes, or lack of insulation, which lead to banging or rattling sounds.

- Installing pipe insulation, securing loose pipes, and adding water hammer arrestors can reduce or eliminate noise.

- Air chambers help absorb shockwaves and prevent banging caused by sudden water flow stops.

- Regular plumbing maintenance and slow valve closures minimize vibrations and noise after system changes.

What Causes Pipes to Bang or Rattle?

Have you ever heard loud banging or rattling noises coming from your pipes? This often happens when water temperature changes suddenly, causing the metal pipes to expand or contract quickly. When pipes aren’t properly insulated, they’re more prone to these movements, leading to banging sounds. Pipe insulation helps cushion these shifts, reducing noise and preventing the pipes from hitting against walls or other surfaces. Rapid temperature fluctuations, like turning on hot water, can cause pipes to move abruptly if they’re not secured well. This expansion and contraction create the rattling or banging noises you hear. Ensuring your pipes are well-insulated and secured minimizes these vibrations, making your plumbing quieter and extending its lifespan. Unique and Wicked Planters offer insights into proper materials and techniques that can also help dampen these sounds.

Understanding Water Hammer and How to Stop It

Water hammer happens when quick-moving water suddenly stops or changes direction, causing loud banging noises in your pipes. You can often recognize it by the sharp, repetitive sounds after turning off a faucet or appliance. To stop it, you’ll need to understand its causes and try simple solutions like adding air chambers or pressure reducers. Additionally, using fresh, properly stored lemon juice can help prevent mineral buildup that might contribute to pipe issues.

Causes of Water Hammer

Ever wonder what causes those sudden banging noises in your pipes after turning off a faucet or appliance? Water hammer happens when water suddenly stops or changes direction, creating shockwaves that travel through your pipes. These shockwaves can cause loud banging, especially if your pipes aren’t properly secured or insulated. Here are some common causes:

- Rapid valve closures, which don’t allow water to slow down gradually.

- Loose or unpadded pipes that amplify noise absorption.

- Lack of pipe insulation, making pipes more vulnerable to shockwaves.

- Insufficient pipe support that allows movement and intensifies noise.

Adding pipe insulation can help dampen the noise and absorb shockwaves, reducing water hammer. Securing pipes firmly also minimizes movement and noise, making your plumbing quieter and safer.

Recognizing Noisy Pipes

When you hear a loud banging or knocking sound in your pipes after turning off a faucet or appliance, it’s a clear sign of water hammer. This noise often indicates that water pressure is too high or that pipes aren’t properly secured. You might notice the sound more in areas with uninsulated pipes or where pipe insulation is missing. Sharp changes in water pressure, such as quickly shutting off a valve, can cause the pipes to vibrate and produce noise. To recognize it, listen for repetitive banging that occurs immediately after turning off water. If you detect these sounds, it’s a sign your pipes need attention. Proper pipe insulation and controlling water pressure can help reduce or eliminate these noisy disturbances. Additionally, understanding the Water Wellbeing Index can help in maintaining optimal water pressure and overall plumbing health.

Solutions and Prevention

To stop water hammer and prevent noisy pipes, you need to address the underlying causes. One effective solution is installing pipe insulation, which dampens vibrations and reduces noise. Additionally, adding noise barriers around pipes can absorb sound and minimize disturbances. You can also consider installing water hammer arrestors, which absorb sudden pressure changes. Here are some key steps:

- Insulate pipes to absorb vibrations and reduce noise.

- Use noise barriers around problem areas to block sound transmission.

- Install water hammer arrestors to prevent sudden pressure shocks.

Implementing these measures helps stabilize water flow, minimizes noise, and protects your pipes from damage. Regular maintenance and proper pipe support also contribute to quieter, longer-lasting plumbing. Incorporating proper pipe support can further reduce movement and noise, ensuring the longevity of your plumbing system.

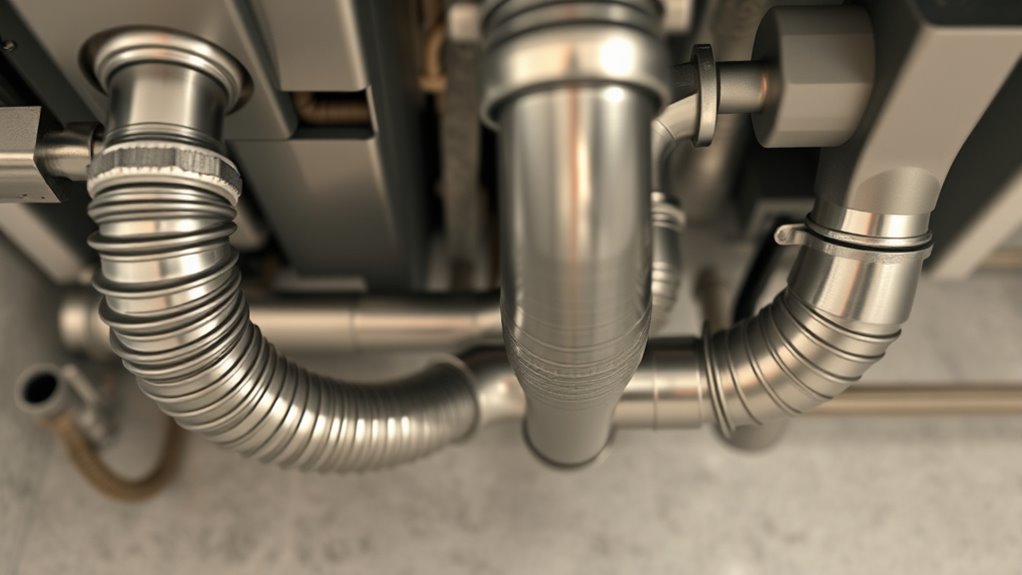

The Role of Air Chambers in Dampening Noise

Air chambers play a crucial role in reducing noise caused by water hammer and pipe vibrations. These specially designed sections of pipe contain air that acts as a cushion, absorbing shock waves from sudden water flow changes. When water quickly stops or shifts direction, the air chamber compresses, preventing loud banging sounds and vibrations from traveling through your pipes. This pressure surge mitigation helps prevent pipe damage and enhances system longevity. Properly installed air chambers are an effective, simple solution to minimize pipe noise after repairs or system changes. They work silently in the background, ensuring your plumbing remains quiet and smooth, especially when water flow fluctuates unexpectedly.

Why Pipes Expand and Contract After Repairs

After repairs or system changes, pipes often expand and contract due to temperature fluctuations and residual stress. This movement occurs because different pipe materials react uniquely to temperature changes, causing them to swell or shrink. Even with pipe insulation, some heat transfer remains, leading to expansion or contraction.

Here are key reasons why this happens:

- Pipe material properties—metal pipes expand more than plastic ones.

- Residual stress from installation or repairs causes movement over time.

- Inadequate pipe insulation allows temperature swings to affect pipe size.

Understanding these factors helps you recognize that pipe movement is natural after repairs. Proper pipe insulation can mitigate excessive expansion or contraction, reducing noise and potential damage.

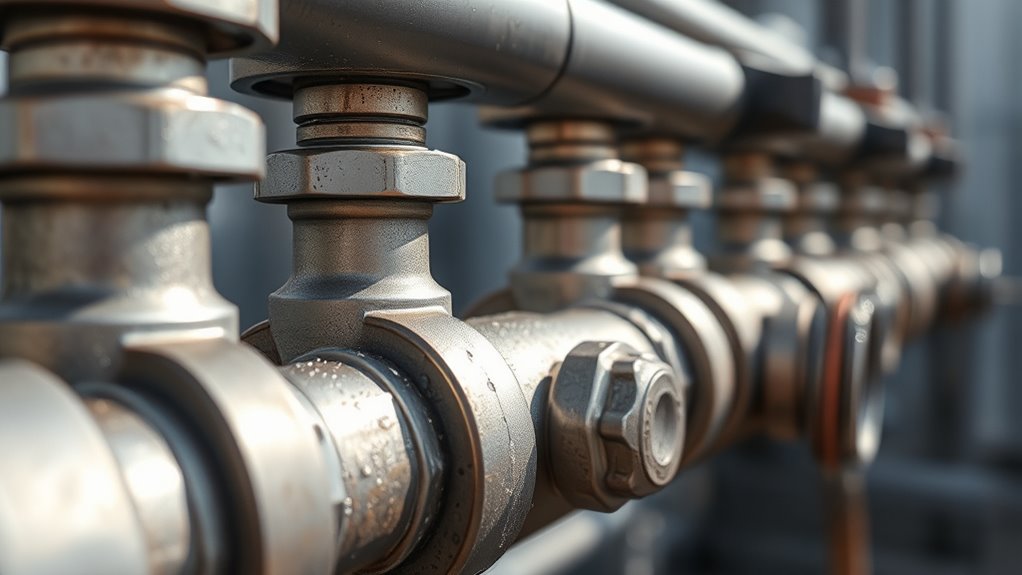

The Significance of Loose or Unsecured Pipes

Loose or unsecured pipes can cause significant noise and vibrations within your plumbing system. When pipes aren’t properly supported with pipe supports, they can rattle or bang against walls and framing as water flows through. This movement creates loud, annoying sounds that can worsen over time. Adding pipe insulation helps dampen vibrations, reducing noise and protecting pipes from temperature fluctuations. Securing your pipes with the right supports prevents movement, minimizes noise, and prolongs pipe life. Without proper support, pipes are more likely to shift or rattle, especially during high water flow or pressure changes. Ensuring your pipes are firmly anchored and insulated not only quiets your plumbing but also prevents damage caused by unnecessary movement. Proper support and insulation are key to maintaining a quiet, reliable plumbing system. Additionally, using appropriate pipe supports can help reduce the risk of pipe damage and noise over time.

How Valves and Fixtures Can Contribute to Noise

Valves and fixtures can create noise through issues like water hammer, sudden flow changes, and air traps. When water suddenly stops or changes direction, it can cause loud banging or knocking sounds. Understanding these common problems helps you identify and fix noisy fixtures more effectively. Using properly functioning apps for tracking water flow or pressure can also help detect irregularities that lead to noise.

Valve Water Hammer

When a valve quickly shuts off or opens, it can cause a loud banging sound known as water hammer. This valve water hammer results from sudden changes in water flow, creating shockwaves that travel through pipes. You might notice this noise after turning off a faucet or shutting a valve abruptly. To understand and prevent valve noise caused by water hammer, consider these points:

- Rapid Valve Closure: Fast shutting valves increase water hammer risk.

- Pressure Surges: Sudden flow changes cause pressure spikes in pipes.

- Mitigation Devices: Installing water hammer arrestors or slow-closing valves reduces noise and damage.

Addressing these issues minimizes valve noise and keeps your plumbing quieter and more durable.

Fixture Air Traps

Water hammer caused by rapid valve closures can create loud banging noises, but fixtures and their air traps also play a significant role in plumbing noise. Air traps, located in sinks, toilets, and other fixtures, help prevent sewer gases from escaping and reduce noise. When air traps become clogged or lose their air cushion, they can cause fixture noise, such as gurgling or banging sounds. Poorly maintained or improperly installed air traps may trap air or debris, disrupting water flow and amplifying noise. Ensuring air traps are clean and functioning correctly minimizes fixture noise and prevents water hammer effects from spreading through the pipes. Properly maintained air traps contribute to quieter plumbing and help maintain a smooth, silent water flow. Regular inspection and air trap maintenance can prevent the buildup of debris that causes noise issues.

Sudden Flow Changes

Sudden changes in water flow caused by quick valve closures or abrupt fixture usage can generate loud banging or knocking noises within your pipes. These noises happen because pressure fluctuations create pipe vibrations that travel through the plumbing system. When flow is suddenly stopped or redirected, the rapid change causes shockwaves, leading to noise. To prevent this, consider these solutions:

- Install water hammer arrestors to absorb pressure spikes.

- Avoid shutting off valves abruptly; close them slowly.

- Secure loose pipes to reduce vibrations and noise.

- Implement pressure regulation to control water flow and minimize shockwaves.

Recognizing Vibrations in Plumbing Systems

Vibrations in plumbing systems are often noticeable as unusual noises or shaking pipes, signaling that something has changed. You might feel or hear these vibrations when running water or even when no fixtures are in use. One common sign is faucet vibrations, which can cause a buzzing or rattling sound. Check if pipes are touching framing or walls, as this can amplify vibrations. Insufficient pipe insulation can also lead to increased movement and noise. Pay attention to any trembling pipes during high water flow, as this indicates loose fittings or pressure issues. Recognizing these vibrations early helps you identify potential problems before they worsen. If vibrations persist, inspecting for loose pipes or adding insulation can often reduce or eliminate the noise.

The Impact of High Water Pressure on Pipe Noises

High water pressure can substantially increase the noise levels in your plumbing system. When water pressure is too high, it causes excessive pipe vibrations that produce banging, rattling, or whistling sounds. These vibrations make the pipes move more than usual, amplifying noise. If your water pressure exceeds recommended levels, you might notice louder noises during everyday use. To understand the impact, consider these points:

High water pressure causes pipe vibrations, leading to loud banging, rattling, and whistling noises in your plumbing system.

- Increased pipe vibrations lead to louder noises.

- High water pressure strains pipe fittings, causing rattles.

- Excessive pressure can cause pipes to bang against walls or other structures.

Reducing water pressure can help diminish these noises, making your plumbing quieter and reducing stress on the pipes. Proper regulation ensures smoother water flow and less disruptive sounds.

When to Call a Professional Plumber

If your pipes keep making noise despite recent changes, it’s time to call a professional. Persistent sounds, complex issues, or safety concerns should never be disregarded. A plumber can diagnose the problem accurately and guarantee your plumbing stays safe and quiet.

Persistent Noise Indicators

When you notice persistent noises coming from your pipes despite recent repairs or adjustments, it’s a clear sign that professional help may be needed. These ongoing sounds could indicate issues like poor pipe insulation or ineffective noise detection. Ignoring these signs might lead to further damage or higher bills.

Consider calling a plumber if you experience:

- Continuous banging or clanking noises, especially after running water

- Whistling sounds during faucet use or when appliances operate

- Frequents rattling or squeaking that persists despite adjustments

Persistent noises often point to underlying problems that require expert diagnosis. Addressing these early can prevent costly repairs later. Remember, professional plumbers can evaluate if pipe insulation needs upgrading or if there’s a more complex issue at play.

Complex Plumbing Issues

Persistent noises from your pipes can sometimes signal more complex issues that require professional attention. If you notice persistent banging or clanking despite adjusting pipe insulation, it might be caused by high water pressure or improper pipe installation. These problems can lead to leaks, burst pipes, or water damage if left unchecked. When your pipes make irregular noises after changes, it’s a sign you should call a plumber. They can assess your water pressure and determine if it’s causing stress on your plumbing system. Additionally, a professional can identify if pipes are improperly secured or if there’s a need for better insulation. Addressing these issues early prevents costly repairs and ensures your plumbing functions smoothly. Don’t delay if you suspect complex plumbing problems.

Safety Concerns Arise

Unusual noises or sudden changes in your plumbing often signal safety concerns that require immediate professional attention. If you notice banging, clanking, or hissing sounds, it could indicate a serious issue with pipe insulation or pressure. Ignoring these signs can lead to water damage or pipe bursts. When addressing noise reduction, a plumber can assess your system for underlying problems. Call a professional if:

- You hear persistent banging or knocking, suggesting pipe movement or high pressure.

- The noise is accompanied by leaks or reduced water flow, risking water damage.

- You notice sudden pipe vibrations or hissing sounds, indicating potential pressure issues or unsafe conditions.

Prompt action ensures your plumbing remains safe and efficient, preventing costly repairs.

Simple Fixes to Reduce or Eliminate Pipe Noise

Many common pipe noises can be considerably reduced with simple adjustments and DIY fixes. One effective method is adding pipe insulation, which enhances noise dampening and prevents pipes from knocking or rattling. Securing loose pipes with brackets or clamps also minimizes movement that causes sound. Additionally, wrapping pipes with foam or rubber sleeves absorbs vibrations. For quick results, check for air chambers or empty sections in your plumbing and fill them with water to eliminate air pockets. Here’s a quick comparison:

| Fix | Effect |

|---|---|

| Pipe insulation | Reduces noise transmission |

| Securing loose pipes | Prevents rattling and knocking |

| Adding noise dampening pads | Absorbs vibrations |

| Filling air chambers | Eliminates air-related noises |

These simple steps often make a noticeable difference in quieting your pipes.

Frequently Asked Questions

Can Pipe Noise Indicate Hidden Plumbing Issues?

Yes, pipe noise can indicate hidden plumbing issues. You might notice noise causes like water hammer or rapid water flow, which cause plumbing vibration. These sounds often signal problems such as loose pipes, high water pressure, or blockages. Ignoring these noises can lead to more serious damage, so it’s best to investigate and address the causes early to prevent costly repairs later.

Are Noisy Pipes a Sign of Impending Pipe Failure?

Yes, noisy pipes can signal impending pipe failure. You might notice unsettling sound vibrations or strange pipe resonance that hint at underlying issues. These noises often stem from water hammer, loose fittings, or aging pipes, all of which can weaken the system over time. Ignoring these sounds could lead to leaks or bursts. Stay alert—addressing the cause early can prevent costly repairs and protect your plumbing’s future.

How Long Does It Take to Fix Noisy Pipes Permanently?

Fixing noisy pipes permanently typically takes a few hours to a day, depending on the issue. You should start with installation tips like securing pipes properly and insulating them to reduce noise. Soundproofing methods, such as using pipe wraps or mounting clips, can make a big difference. If you’re comfortable, tackling these yourself works, but for complex problems, calling a plumber guarantees a lasting solution.

Do Materials Like Copper or PVC Affect Pipe Noise Levels?

You’ll notice that pipe material impacts noise levels, like in a case where copper pipes produced less noise than PVC. Copper’s dense composition dampens vibrations better, reducing noise, while PVC’s lighter, more flexible nature can amplify sound. So, your choice of pipe material markedly influences how noisy your plumbing will be. Opting for materials like copper can help keep your pipes quieter and minimize disturbances.

Can Insulation Reduce Pipe Noise Effectively?

Yes, pipe insulation can effectively reduce noise. When you wrap your pipes with proper insulation, it dampens vibrations and minimizes sound transmission, especially from water flow or pipe expansion. Using foam or rubber insulation creates a barrier that absorbs noise, making your home quieter. So, if you’re dealing with noisy pipes, applying pipe insulation is a simple, affordable way to improve noise reduction and enhance your comfort.

Conclusion

Think of your pipes as the strings of a delicate instrument, resonating with every change in your home’s rhythm. When they start to bang or rattle, it’s like a discord in your home’s symphony. By understanding the causes and applying simple fixes, you can restore harmony. Remember, addressing these noises is like tuning a guitar—small adjustments can bring back the sweet, silent melody your home deserves.