To prevent and manage leaks at unions and threads, you need to understand their fundamentals, choose compatible materials, and follow proper installation techniques. Regular inspections, advanced detection tools, and proactive maintenance help catch early signs of leaks. Knowing common causes like corrosion and improper assembly allows you to respond quickly and implement safety measures. Staying informed about best practices will strengthen your system’s integrity. Keep exploring this guide to master leak prevention and safety strategies in detail.

Key Takeaways

- Proper material selection and compatibility prevent galvanic corrosion and ensure long-term seal integrity.

- Regular inspections and advanced leak detection tools help identify early leak signs and prevent system failures.

- Correct installation practices, including proper torque and thread preparation, reduce leak risks at unions and threads.

- Immediate leak response plans involve containment, source identification, and system shutdown to minimize hazards.

- A proactive safety culture emphasizes maintenance, monitoring, and staff training to sustain leak-free, safe operations.

Understanding the Fundamentals of Unions and Threads

Understanding the fundamentals of unions and threads is essential for ensuring thread safety and avoiding data corruption. Union types define how different data elements share memory space, which impacts how threads access and modify data. Knowing the various union types helps you select the right one for your application, preventing conflicts and leaks. Thread standards, such as ISO and ANSI, set the guidelines for thread dimensions, pitch, and compatibility, ensuring secure and reliable connections. When you understand these standards, you can properly identify compatible components and avoid mismatched fittings that could cause leaks. Proper knowledge of union types and thread standards allows you to design systems that maintain integrity under pressure, reducing maintenance costs and increasing safety. Mastering these fundamentals is vital for effective leak prevention and safe mechanical operations. Additionally, understanding the security implications of digital infrastructure, such as cybersecurity vulnerabilities, can help prevent potential breaches that threaten system integrity.

Common Causes of Leaks in Mechanical Connections

Many leaks in mechanical connections stem from improper assembly or maintenance issues. Corrosion issues weaken seals and threads, causing leaks over time. Design flaws, like inadequate sealing surfaces or mismatched components, also contribute considerably. These problems often lead to costly repairs and safety hazards. Recognizing the emotional impact, consider how overlooked details can jeopardize safety and cause frustration. Here’s a quick overview:

| Cause | Effect | Emotional Impact |

|---|---|---|

| Corrosion issues | Material breakdown, leaks | Fear of failure, safety risks |

| Design flaws | Poor fit, sealing failures | Frustration, loss of trust |

| Improper assembly | Loose connections, leaks | Anxiety, potential accidents |

Additionally, proper maintenance plays a crucial role in preventing leaks and ensuring long-term safety. Addressing these causes ensures safer, leak-free connections.

Recognizing Early Signs of Potential Leak Risks

Early detection of potential leak risks relies on paying close attention to subtle signs that may indicate trouble brewing. Recognizing these signs helps you perform effective leak source identification and conduct thorough leak risk assessment. Keep an eye out for:

Early leak signs help prevent costly system failures through vigilant monitoring.

- Slight discoloration or corrosion around joints and threads

- Moisture or damp spots that appear unexpectedly

- Unusual noises like hissing or dripping sounds

- Small puddles or residue buildup near connections

- Family photoshoot fails such as pet antics or unexpected photobombs can also serve as visual indicators of underlying issues in related contexts.

These indicators often signal an emerging leak. Addressing them early prevents larger failures and reduces maintenance costs. By staying vigilant, you can identify potential leak risks before they escalate, ensuring the safety and integrity of your systems. Proper leak source identification and risk assessment are key to maintaining reliable, leak-free operations.

Material Selection and Compatibility for Leak Prevention

Choosing the right materials is essential for preventing leaks, as incompatible or low-quality options can lead to deterioration and failure over time. Ensuring material compatibility is vital, as mismatched metals or plastics can cause galvanic corrosion, weakening joints. Prioritize materials with high corrosion resistance, especially in harsh environments, to extend the lifespan of your fittings. Select corrosion-resistant alloys or plastics suited for your specific liquids and conditions. Confirm that all components are compatible to avoid chemical reactions that compromise seal integrity. When you choose proper materials, you reduce the risk of leaks, maintain system reliability, and save costs on repairs. Material selection is a fundamental step in leak prevention, highlighting the importance of understanding both compatibility and corrosion resistance for long-term safety. Additionally, considering the material properties can help ensure durability and performance over time.

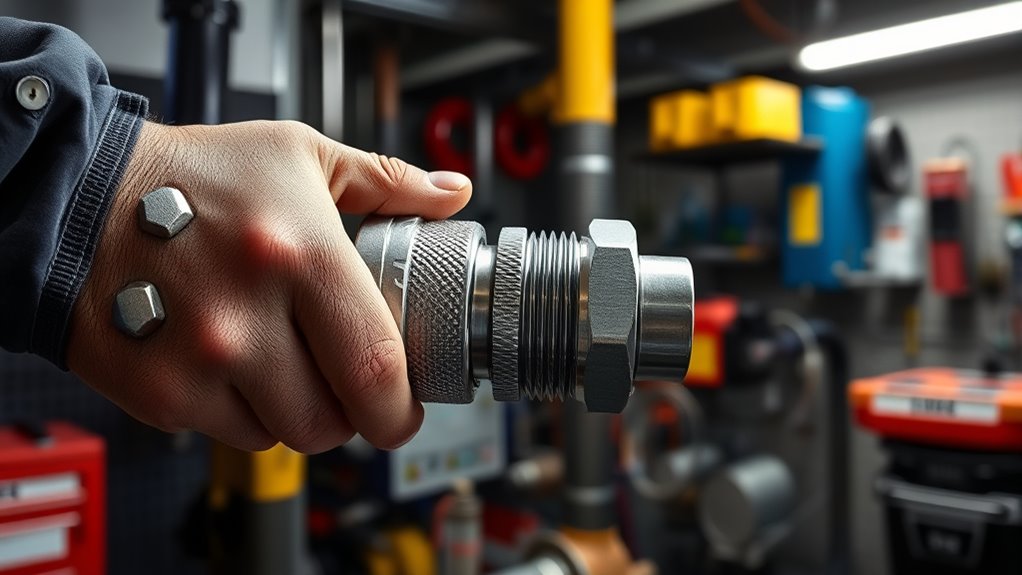

Proper Installation Techniques for Secure Fittings

Proper installation techniques are critical to guaranteeing your fittings stay secure and leak-free. To achieve this, focus on three key steps.

- Check thread compatibility: Ensure the threads match perfectly to prevent cross-threading and leaks.

- Select appropriate sealing materials: Use the right sealing tapes or compounds suited for your fittings to enhance leak prevention.

- Apply sealing materials correctly: Wrap tapes clockwise and avoid over-tightening, which can damage threads and compromise seal integrity.

- Tighten fittings properly: Use the correct tools and torque specifications to avoid over or under-tightening, which can lead to leaks or fitting failure.

- Be aware of potential issues related to Dream symbolism: Understanding dream-related themes of safety and security can inspire more cautious installation practices to prevent leaks and failures.

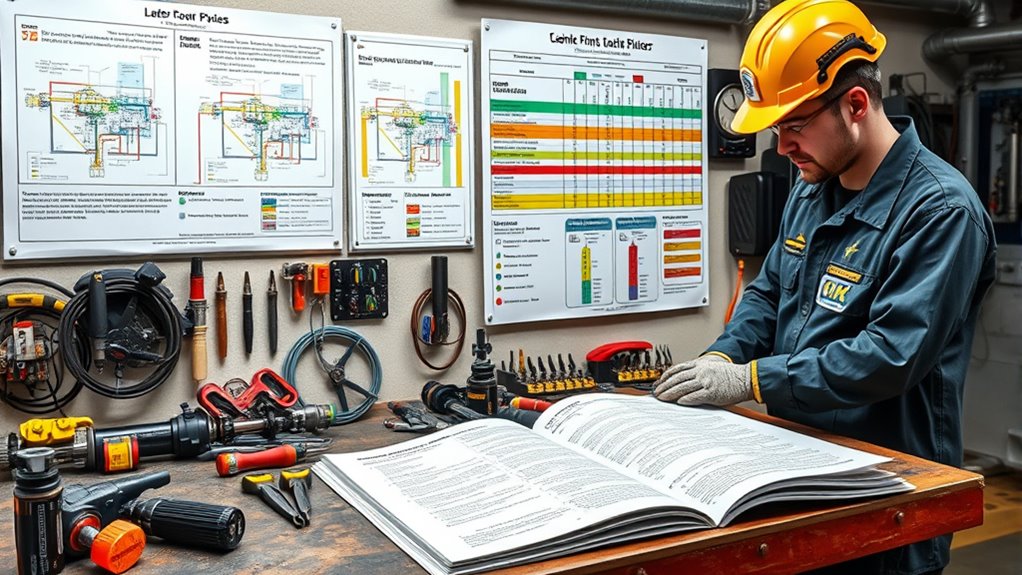

Routine Inspection and Maintenance Protocols

Regular inspection and maintenance are essential to guarantee your fittings remain secure and leak-free over time. By routinely checking for signs of wear, you ensure the material durability of your components stays intact. Pay close attention to corrosion resistance, especially in harsh environments, which can weaken threads and cause leaks. Regularly tighten fittings as needed, but avoid over-tightening, which can damage threads. Use visual inspections to identify rust, pitting, or corrosion that compromise integrity. Maintaining proper lubrication and cleaning also helps preserve sealing surfaces. Implementing a scheduled maintenance protocol helps catch issues early, reducing the risk of leaks and costly repairs. Ultimately, consistent inspections keep your system safe, reliable, and efficient, extending the lifespan of your fittings and safeguarding your operations.

Tools and Technologies for Leak Detection

Advances in leak detection tools and technologies have considerably improved your ability to identify leaks quickly and accurately. Modern methods focus on evaluating seal integrity and conducting pressure testing to pinpoint issues. Here are key tools you should know:

Modern leak detection tools greatly enhance quick, accurate identification and ensure system safety and integrity.

- Ultrasonic Leak Detectors: Detect high-frequency sounds from escaping gases or liquids, enabling early leak identification.

- Infrared Thermography: Visualizes temperature differences caused by leaks, especially useful in complex systems.

- Pressure Testing Devices: Apply controlled pressure to verify system integrity and locate weak points.

- Dye Penetrant Inspection: Uses dye to reveal cracks or leaks in joints and threaded connections.

– Incorporating advanced detection methods such as infrared thermography and ultrasonic sensors can significantly increase the accuracy and speed of leak identification.

These technologies enhance leak detection precision, reduce downtime, and ensure safety by maintaining system integrity.

Best Practices for Repair and Replacement

When repairing or replacing leaks, choosing the right tools guarantees safety and effectiveness. Using correct installation techniques helps prevent future issues and maintains system integrity. Additionally, establishing a regular inspection schedule catches problems early and keeps everything running smoothly. Incorporating proper tuning techniques can further optimize system performance and longevity.

Proper Tool Selection

Choosing the right tools is crucial for safe and effective repairs or replacements. Guaranteeing compatibility with hoses and seal materials prevents leaks and damage. Here are key considerations:

- Confirm hose compatibility to avoid mismatched fittings that could cause leaks.

- Use the correct wrench size to prevent damaging threads or seals.

- Select tools designed for the seal material—some materials require gentle handling.

- Have a variety of thread sealant tools to ensure proper application without over-tightening.

- Always inspect seal integrity after installation to ensure a leak-free connection.

Using appropriate tools reduces the risk of damaging threads or seals, which is essential for leak prevention. Always verify that your tools match the specifications of the hose and seal material involved. Proper selection helps maintain system integrity and prolongs component lifespan, ensuring safe, leak-free operation.

Correct Installation Techniques

Proper installation techniques are vital to guarantee your repairs and replacements stay secure and leak-free. Ensure you select the right seal compatibility to prevent leaks, matching the seal type to your system’s materials. Applying proper thread torque prevents over-tightening or under-tightening, which can cause damage or leaks. Always clean threads before installation for a smooth fit. Use a torque wrench and follow manufacturer specifications for ideal results. Here’s a quick reference:

| Seal Compatibility | Thread Torque | Common Mistakes |

|---|---|---|

| Correct seal type | Proper torque | Over-tightening |

| Incompatible seal | Excessive torque | Under-tightening |

| Material match | Adequate torque | Skipping thread prep |

| Seal integrity | Consistent torque | Ignoring manufacturer |

Following these practices ensures a secure, leak-free connection every time. Proper thread preparation and choosing the right materials are also essential to maintaining system integrity, especially considering the importance of lifestyle factors in overall system performance.

Regular Inspection Schedule

Regular inspections are essential for maintaining system integrity and preventing costly failures. By scheduling routine checks, you ensure leaks are caught early and corrosion is prevented. Consider these key practices:

- Perform pressure testing periodically to verify joint integrity.

- Inspect threads and unions for signs of corrosion or wear.

- Replace worn or damaged components promptly.

- Maintain a documented inspection log for tracking issues and repairs.

- Use essential oils to help prevent microbial growth and maintain cleanliness in certain system components.

These steps help you detect potential problems before they escalate. Regular pressure testing confirms your system’s safety, while corrosion prevention measures extend component lifespan. Staying proactive with inspections minimizes downtime and costly repairs, ensuring your system remains safe and reliable. Consistency in your inspection schedule is crucial for long-term system performance and safety.

Developing a Leak Response and Emergency Plan

You need a clear plan for when leaks happen, starting with proper identification procedures. Once a leak is confirmed, follow immediate response steps to control the situation quickly. Finally, guarantee everyone knows how to communicate during emergencies with an effective communication plan.

Leak Identification Procedures

How can you quickly and accurately identify a leak before it causes significant damage? Start by monitoring seal integrity regularly through visual inspections and pressure testing. These methods help detect early signs of failure. To improve leak detection, follow these steps:

- Conduct routine pressure testing to verify system integrity.

- Use leak detection equipment like ultrasonic detectors or soap solutions.

- Watch for unusual pressure drops or fluctuations.

- Listen for hissing sounds indicating escaping gases or liquids.

Timely identification minimizes risks and prevents costly repairs. Incorporate a leak response plan that emphasizes thorough pressure testing and seal integrity checks. Being proactive ensures you catch leaks early, reducing the chance of escalation and maintaining system safety.

Immediate Response Steps

Developing an effective leak response and emergency plan is essential for minimizing damage and ensuring safety. Your plan should prioritize leak containment to prevent further spread of hazardous materials. Quickly identify the leak’s source and isolate it to reduce risk. Use proper hazard mitigation techniques, such as shutting off valves or activating emergency shut-down systems, to limit exposure. Have clear procedures for deploying containment equipment and securing the affected area. Train your team regularly so they understand their roles during an incident. Staying prepared helps you react swiftly, reducing environmental impact and protecting personnel. Remember, a well-designed response plan can make all the difference in controlling leaks and preventing escalation. Regular review and drills ensure your team remains ready for any leak emergency.

Emergency Communication Plan

Effective communication during a leak emergency is crucial for coordinating response efforts and ensuring safety. You must develop a clear emergency communication plan that addresses pressurized systems and chemical compatibility. To do this, consider these steps:

- Establish immediate alert procedures for leak detection.

- Designate key personnel responsible for communication and response actions.

- Use compatible communication devices resistant to chemical exposure.

- Regularly train staff on emergency protocols, emphasizing leak-specific hazards.

Make sure your plan includes procedures for informing responders about chemical compatibility issues and pressurized system risks. Clear, timely communication minimizes confusion and accelerates containment, protecting both personnel and the environment. An effective plan ensures everyone knows their role, reducing response time and preventing escalation.

Training and Safety Culture for Leak Prevention

Creating a strong safety culture and providing extensive training are essential steps in preventing leaks and ensuring thread integrity. Your team must understand leak prevention strategies and how to identify potential issues early. Safety training should focus on proper threading techniques, recognizing warning signs, and maintaining equipment to prevent leaks. Encourage open communication and accountability to reinforce safety practices consistently. When everyone is well-trained and committed to safety, the risk of leaks diminishes markedly. Regular refresher courses and hands-on drills help keep safety top of mind. By fostering a proactive safety culture, you empower your team to prioritize leak prevention and uphold the integrity of threads, reducing downtime and avoiding costly repairs.

Frequently Asked Questions

How Do Environmental Factors Influence Leak Risks in Unions?

Environmental factors greatly influence leak risks in unions by causing environmental stress and accelerating material degradation. Harsh conditions like extreme temperatures, moisture, and corrosive elements weaken the union’s integrity over time. You should regularly inspect unions exposed to such conditions, as environmental stress can lead to cracks or corrosion, increasing leak chances. Proper maintenance and selecting materials resistant to these factors help reduce the risk and ensure safer, longer-lasting connections.

What Are the Long-Term Effects of Repeated Leak Repairs?

Repeated leak repairs can weaken union and thread integrity over time, increasing the risk of future leaks. To minimize this, you should focus on effective stress management techniques and maintain strict quality assurance protocols. Properly managing stress during repairs guarantees precision, while quality assurance verifies the durability of each fix. Over time, these practices help prevent further damage, extend the lifespan of joints, and reduce the need for frequent repairs.

Can Routine Maintenance Completely Eliminate Leak Occurrences?

Like a steady hand on a ship’s wheel, routine maintenance can ensure leaks, but it can’t fully eliminate them. Preventive inspections catch potential issues early, and proper material selection guarantees durability. However, wear and tear—like the tide—still occur over time. So, while diligent upkeep minimizes leaks, it doesn’t guarantee complete prevention, requiring ongoing vigilance and adaptation to changing conditions.

How Does Corrosion Impact the Integrity of Threaded Connections?

Corrosion effects markedly weaken the integrity of threaded connections by causing thread degradation. When corrosion occurs, it eats away at the metal, reducing the strength and fit of the threads. This deterioration makes connections more prone to leaks, failures, and potential accidents. To maintain reliability, you need to regularly inspect and address corrosion effects, ensuring your threaded connections stay secure and functional over time.

What Are Emerging Technologies for Proactive Leak Prevention?

Think of your system as a vigilant guardian, constantly watching for trouble. Emerging technologies like smart sensors act as its eyes, detecting tiny leaks before they become disasters. Coupled with predictive analytics, these tools forecast potential failures, enabling proactive leak prevention. By integrating these innovations, you transform your operations into a well-oiled machine, catching issues early and safeguarding your infrastructure from costly damage and safety hazards.

Conclusion

By understanding the fundamentals, recognizing early signs, and following best practices, you can stay ahead of leaks and prevent costly mishaps. Proper material choices, installation, and regular maintenance are your best defense. Remember, an ounce of prevention is worth a pound of cure—staying vigilant and proactive keeps everything running smoothly. When every detail matters, you’ll turn the tide in your favor and keep your systems leak-free and safe for all.