To become confident handling air in lines after service, start by understanding how compressed air systems work and the importance of maintaining proper pressure and cleanliness. Always follow safety precautions, such as wearing protective gear and ensuring lines are depressurized before working on them. Regularly inspect, clean, and tighten fittings, and troubleshoot any leaks or pressure issues promptly. Knowing these basics sets a strong foundation, and there’s more to explore for complete mastery.

Key Takeaways

- Always depressurize and inspect lines before handling to ensure safety and prevent leaks.

- Confirm proper reconnecting of lines and fittings to maintain system integrity.

- Gradually restore pressure and check for leaks using soap solution or listening methods.

- Regularly verify air pressure and flow to ensure system performance and safety.

- Perform routine maintenance, including filter cleaning and connection inspections, to build confidence in system operation.

Understanding the Air in Lines System

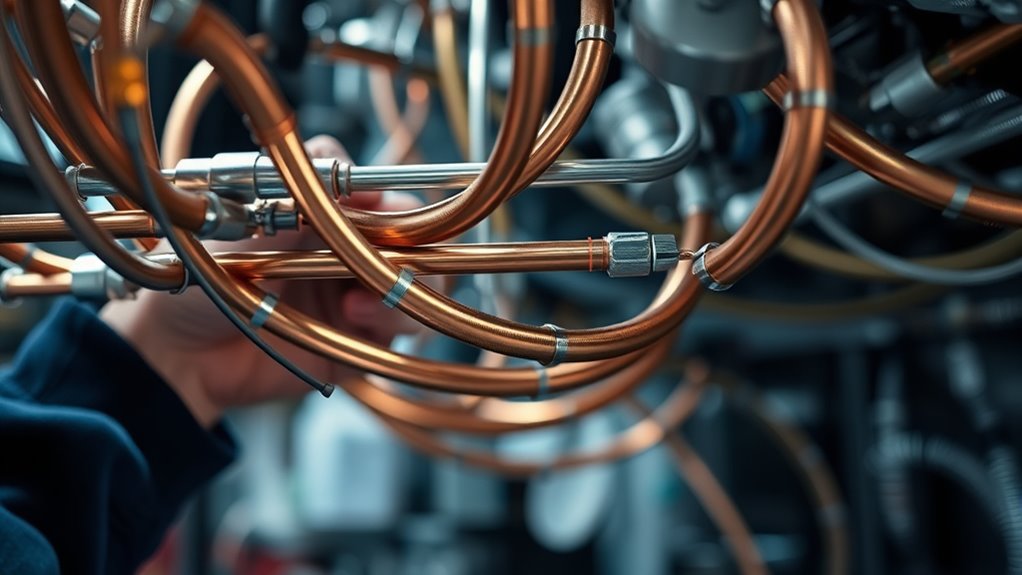

Understanding the air in lines system is essential for maintaining efficient and reliable operation. You need to grasp how your air compressor supplies compressed air and how pressure regulation controls the flow. The compressor generates pressurized air, which travels through lines to power tools or equipment. Proper pressure regulation ensures the air pressure remains consistent, preventing damage and ensuring ideal performance. If pressure is too high, it can cause leaks or equipment failure; if too low, tools won’t operate correctly. Regularly checking and adjusting pressure regulators helps maintain the right pressure levels. Additionally, utilizing appropriate glycolic acid products can help in maintaining the cleanliness and integrity of your system components. By understanding how your air compressor interacts with the lines and pressure regulation, you can troubleshoot issues more effectively and keep your system running smoothly.

Essential Safety Precautions Before Handling Air Lines

Before handling air lines, it’s crucial to prioritize safety to prevent injuries and equipment damage. Always wear the appropriate personal protective equipment, such as safety goggles and gloves, to guard against accidental releases or debris. Make certain proper oxygen monitoring before working with compressed air systems; low oxygen levels can pose serious health risks. Confirm that the air lines are depressurized and free of contaminants to avoid sudden releases of pressurized air. Check for leaks and damaged fittings, which could cause injury or equipment failure. Remember, handling air lines safely requires a cautious approach—never bypass safety protocols. Properly equipped and informed, you’ll minimize risks and ensure a safer working environment. Incorporating industry best practices can further enhance safety measures and reduce potential hazards.

Step-by-Step Procedures for Air Line Maintenance

Are you ready to perform maintenance on air lines safely and effectively? First, verify the air quality meets safety standards by inspecting for moisture or contaminants. Begin by shutting off the air supply and releasing residual pressure from the lines. Next, disconnect the lines carefully, noting their connections for proper reassembly. Clean or replace filters if necessary, and inspect for wear or damage. Record each step in your maintenance records, including parts replaced and observations. Additionally, ensure that the air quality remains optimal throughout the process to prevent system failures. Once completed, reconnect the lines securely and gradually restore air pressure, checking for leaks. Confirm the air quality remains ideal after maintenance. Keeping detailed records helps track maintenance history and ensures ongoing safety and performance of your air system.

Troubleshooting Common Air Line Issues

When you encounter issues with your air lines, quick and accurate troubleshooting can save time and prevent equipment damage. Start by checking the air pressure; inconsistent or low pressure often indicates a leak or obstruction. For leak detection, listen for hissing sounds or use a soap solution to spot bubbles at fittings and joints. Ensure all connections are tight and seals are intact. Inspect the entire line for visible damage or wear. Remember to verify the compressor’s output to rule out supply issues. Additionally, understanding Gold IRA Rollovers can help diversify your assets and protect your investments during equipment downtimes.

- Confirm proper air pressure levels

- Conduct leak detection with soapy water

- Tighten fittings and replace damaged seals

- Check for line kinks or damage

Addressing these common issues helps maintain ideal airflow and prevents further problems.

Best Practices for Post-Service Air Line Checks

Performing thorough post-service checks on your air lines guarantees they remain in ideal condition and ready for reliable operation. Start by inspecting connections for tightness and signs of wear, ensuring no leaks exist. Follow airline regulations to confirm all safety standards are met, documenting your findings for compliance. Incorporate maintenance scheduling into your routine, setting regular intervals for detailed inspections and testing. Use appropriate tools to verify air pressure and flow, addressing any irregularities immediately. Always check for proper filtration and moisture removal systems to prevent corrosion or damage. Regular cleaning of filters and hoses prevents clogs and prolongs equipment lifespan. Consistent post-service checks help catch issues early, reducing downtime and ensuring safety. Adhering to airline regulations and maintaining a disciplined schedule keeps your air lines in top shape and ready for the next operation.

Frequently Asked Questions

How Often Should Air Lines Be Inspected for Optimal Safety?

You should inspect air lines regularly, ideally every 6 months or sooner if you notice any issues. These inspection intervals help guarantee air line durability and safety. During inspections, check for leaks, cracks, or signs of wear that could compromise performance. Consistent inspections not only prevent potential failures but also extend the lifespan of your air lines, keeping your system safe and reliable.

What Are the Signs of a Failing Air Line Connection?

You’ll notice signs of a failing air line connection if you experience air pressure issues, like inconsistent or dropping pressure, or if you hear hissing sounds indicating connection leaks. These leaks can also cause the system to lose efficiency or fail to operate properly. Regularly check for visible signs of wear, cracks, or loose fittings, and address any issues promptly to prevent further damage and maintain safe, reliable operation.

Can I Perform Air Line Maintenance Without Specialized Tools?

Think of air line maintenance like fixing a delicate musical instrument—you need the right tools for perfect harmony. You can perform basic maintenance without specialized tools if you follow proper procedures and adhere to air line certification standards. Always review maintenance procedures carefully, verify you have the right parts, and handle connections gently. However, for complex tasks, it’s best to consult a professional to avoid causing more issues.

What Are the Environmental Impacts of Improper Air Line Disposal?

Improper disposal of airline lines can harm the environment, violating airline regulations. You should follow proper recycling methods to guarantee safe disposal, preventing leaks of hazardous materials like oils or refrigerants. By adhering to regulations and recycling guidelines, you protect ecosystems and reduce pollution. Always consult your airline’s waste management protocols and local environmental laws to dispose of airline lines responsibly and minimize environmental impacts.

How Do Weather Conditions Affect Air Line Performance and Safety?

Weather conditions considerably influence airline efficiency and safety. Weather variability, like rain, snow, or high humidity, can cause moisture buildup, leading to corrosion or blockages. Temperature effects also matter; extreme cold can make lines brittle and prone to cracking, while heat may cause expansion, increasing the risk of leaks. Always inspect and maintain air lines regularly, especially during weather changes, to guarantee the best safety and performance.

Conclusion

Mastering air in lines after service is like tending to a delicate garden—you must care for each element to guarantee everything blooms safely. By understanding the system, following safety steps, and troubleshooting effectively, you’ll keep your lines running smoothly. Think of yourself as a guardian, much like a craftsman perfecting each detail. With these skills, you’ll confidently navigate any challenge, turning a complex task into a seamless part of your routine.