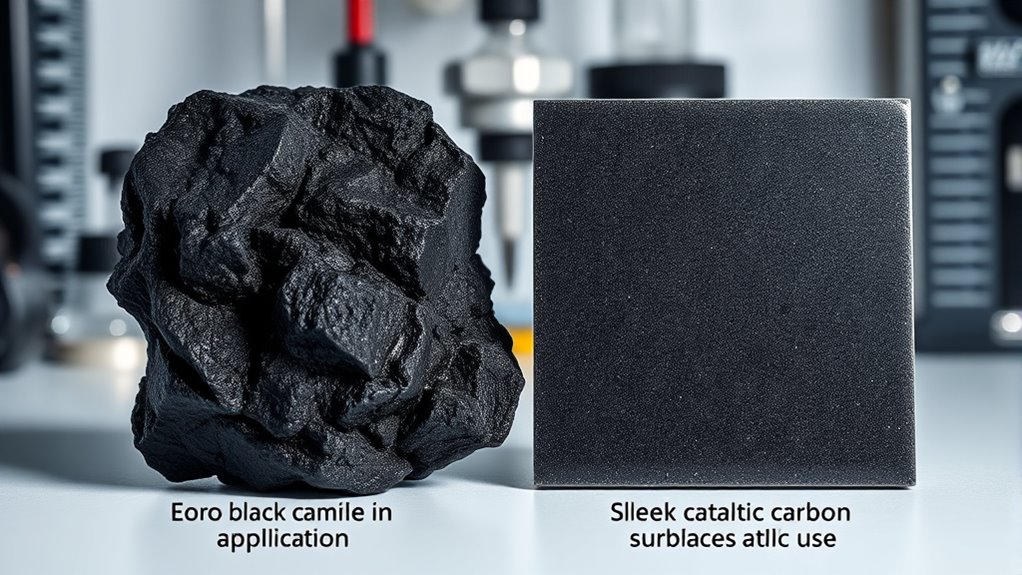

If you want to understand the difference between carbon and catalytic carbon, start with their composition; traditional carbon includes graphite and activated carbon with porous, layered structures, while catalytic carbon has added surface features for enhanced reactions. Catalytic carbon offers higher performance in catalysis and filtration, but at a higher cost. Knowing these differences helps you choose the right material for your needs—if you’re curious about how these materials evolve and their future, keep exploring.

Key Takeaways

- Traditional carbon is mainly pure carbon (graphite, activated carbon), while catalytic carbon has added active sites for chemical reactions.

- Catalytic carbon offers enhanced reactivity, durability, and selectivity compared to standard carbon materials.

- Both types are sourced from organic materials, but catalytic carbon often involves additional activation and impregnation steps.

- Traditional carbon is cost-effective and widely used; catalytic carbon provides higher performance at a higher initial cost.

- Innovations like nanotechnology and renewable sourcing are shaping future developments in both carbon types.

Understanding the Composition of Traditional Carbon

Traditional carbon mainly consists of allotropes of carbon, with graphite and activated carbon being the most common forms. Your understanding of its carbon structure is key to grasping its material composition. Graphite features layers of carbon atoms arranged in a hexagonal lattice, giving it a crystalline, layered structure. Activated carbon, on the other hand, has a porous, high-surface-area structure designed for adsorption. Both forms are primarily pure carbon, but their differences in structure influence their properties and applications. The carbon structure determines how atoms bond and arrange themselves, affecting strength, conductivity, and reactivity. Recognizing these variations helps you appreciate how traditional carbon serves various industries, from energy storage to filtration, based on its specific material composition. Additionally, the duration of copyright protection and the indefinite renewal potential for trademarks highlight the importance of understanding intellectual property characteristics when developing new carbon-based technologies.

The Role of Catalytic Carbon in Industry

Catalytic carbon plays a crucial role in improving chemical reactions, making processes more efficient and cost-effective. It also helps in purification and filtration, ensuring cleaner products and environments. Additionally, advancements in sound synthesis techniques enable the development of more precise and tailored catalytic materials, further enhancing their effectiveness. By reducing environmental impacts, catalytic carbon supports sustainable industrial practices you can rely on.

Enhancing Chemical Reactions

Enhancing chemical reactions is essential for increasing efficiency and reducing costs in industrial processes, and catalytic carbon plays a critical role in this effort. By improving catalytic efficiency, it accelerates reactions while requiring less energy, which directly lowers your carbon footprint. Catalytic carbon’s unique surface properties enable it to facilitate reactions more effectively than traditional methods, making processes faster and more sustainable. As you optimize your industrial operations, integrating catalytic carbon can lead to significant environmental benefits and cost savings. Its ability to boost reaction rates without compromising quality means you can produce more with less, aligning your goals of efficiency and environmental responsibility. Additionally, understanding the types of headphone jacks can enhance communication and safety during industrial operations involving audio equipment. Ultimately, catalytic carbon helps you achieve a more sustainable and profitable industrial workflow.

Purification and Filtration

Building on the benefits of catalytic carbon in improving reaction efficiency, its role in purification and filtration has become increasingly significant across various industries. You’ll find catalytic carbon excels due to its adsorption mechanisms, which trap impurities effectively. Its pore structure provides a high surface area, enhancing contaminant removal. This makes it ideal for filtering water, air, and industrial liquids. Additionally, vetted options are available to ensure quality and effectiveness across different applications. Key points include: 1. The pore structure allows for selective adsorption of pollutants. 2. Adsorption mechanisms capture organic compounds and odors. 3. Catalytic properties enable breakdown of certain contaminants. 4. Enhanced surface area improves filtration efficiency.

Environmental Impact Reduction

Harnessing catalytic carbon in industry substantially reduces environmental impacts by enabling more efficient removal of pollutants from air, water, and waste streams. It helps lower your company’s carbon footprint by maximizing the use of renewable sources for regeneration and reducing waste. Catalytic carbon’s enhanced activity means fewer resources are needed, cutting down emissions and energy consumption. This shift promotes sustainability and aligns with eco-friendly practices. Consider this comparison:

| Aspect | Traditional Carbon | Catalytic Carbon |

|---|---|---|

| Regeneration | Less efficient | More efficient |

| Environmental impact | Higher | Lower |

| Resource use | Higher | Lower |

| Carbon footprint | Larger | Smaller |

Adopting catalytic carbon supports your sustainability goals by minimizing environmental harm and fostering greener industry practices. Utilizing leverage in manufacturing processes can further optimize resource efficiency and reduce costs.

Key Properties That Differentiate Carbon Types

Different types of carbon exhibit distinct properties that influence their performance and suitability for various applications. Two key properties are adsorption capacity and surface area. These properties determine how effectively the material can trap molecules or contaminants. A new sentence with sound vibrations and the rest of the sentence.

Manufacturing Processes for Each Material

You’ll see that the production techniques for carbon and catalytic carbon involve distinct methods, starting with raw material preparation. In carbon manufacturing, you typically use processes like pyrolysis of organic materials, while catalytic carbon often requires specific activation and impregnation steps. Understanding these key steps helps clarify how each material’s unique properties are achieved during production. Additionally, somatic therapy techniques such as breathwork and movement therapy are employed to enhance emotional healing and physical awareness.

Production Techniques Overview

Have you ever wondered how carbon and catalytic carbon are produced? The manufacturing processes vary markedly, impacting their applications like graphene and carbon nanotubes.

- Pyrolysis — heating organic materials in the absence of oxygen creates pure carbon structures.

- Chemical Vapor Deposition (CVD) — introduces gases like methane to form thin carbon layers, essential for graphene applications.

- Graphitization — transforms amorphous carbon into crystalline graphite, which can be processed into carbon nanotubes.

- Activation — involves chemical or physical treatment to increase surface area, vital for catalytic activities.

These techniques influence the purity, structure, and performance of both carbon and catalytic carbon, shaping their roles in advanced materials and nanotechnology.

Raw Material Preparation

Preparing the raw materials for carbon and catalytic carbon involves distinct steps that determine their final properties. For carbon, raw material sourcing focuses on selecting high-quality organic sources like coal, biomass, or petroleum coke, which influence purity and structure. Catalytic carbon requires not only sourcing appropriate carbon sources but also incorporating catalysts during preparation, often involving chemical treatments. Graphene enhancement plays a role here by modifying raw materials to improve conductivity and surface area, boosting performance in applications. The preparation process involves cleaning, grinding, and sometimes activating the raw materials to optimize their porosity and surface characteristics. Precise control during sourcing and initial treatment guarantees the materials develop the desired properties, ultimately affecting the efficiency and application of both carbon types. Additionally, understanding the exfoliation process can further enhance the surface area and reactivity of the materials, leading to improved performance in various applications.

Applications and Use Cases of Carbon Materials

Carbon materials play a crucial role across a wide range of industries due to their unique properties such as high surface area, excellent electrical conductivity, and chemical stability. You’ll find them in applications like lightweight carbon fiber components for aerospace, durable activated charcoal for filtration, and conductive materials in electronics. These versatile materials are essential for:

- Reinforcing composites in aerospace and automotive industries.

- Filtering pollutants and toxins with activated charcoal.

- Enhancing battery performance with conductive carbon additives.

- Creating high-performance electrodes for energy storage devices.

Their high surface area makes them ideal for adsorption and catalysis, while carbon fiber provides strength without adding weight. Additionally, material properties such as durability and conductivity make them suitable for advanced technological applications. Whether for structural or functional uses, understanding these applications helps you appreciate carbon’s vital contributions to technology and sustainability.

Environmental Impact and Sustainability Aspects

While carbon materials offer valuable benefits across industries, their environmental footprint raises important sustainability concerns. Traditional carbon sources often rely on fossil fuels, increasing the carbon footprint and depleting non-renewable resources. This reliance emphasizes the need for renewable sourcing to reduce environmental harm. The choice between carbon and catalytic carbon impacts ecosystems, air quality, and climate change. Additionally, exploring Best Beaches can serve as a reminder of the importance of preserving natural environments for future generations.

Advantages and Limitations of Traditional Vs Catalytic Carbon

Traditional carbon materials have long been valued for their affordability and widespread availability, making them a go-to choice across industries. Their advantages include ease of use, proven performance, and established supply chains. However, they also have limitations.

Traditional carbon materials are affordable, reliable, and widely available, but may lack the performance of catalytic alternatives.

- Cost comparison: Traditional carbon is generally cheaper upfront but may require more frequent replacement.

- Market availability: It’s readily accessible, ensuring consistent supply.

- Efficiency: Catalytic carbon often offers higher activity and selectivity but at a higher initial cost.

- Durability: Catalytic carbon tends to last longer and perform better in demanding conditions.

While traditional carbon is cost-effective and easy to access, catalytic carbon provides enhanced performance, though with higher investment and complexity.

Future Trends and Innovations in Carbon Technologies

Advancements in carbon technologies are rapidly shaping the future of industries ranging from energy to environmental remediation. One key trend is nanotechnology integration, which enhances carbon materials’ surface area and reactivity, boosting efficiency in applications like filtration and energy storage. Additionally, there’s a strong movement toward sourcing carbon from renewable resources, reducing reliance on fossil fuels and lowering environmental impact. Innovations are also focusing on developing sustainable, scalable methods for producing high-performance carbon materials. Researchers are exploring bio-based feedstocks and waste-derived carbon to promote circular economies. These trends aim to create more environmentally friendly, cost-effective solutions that meet growing global demands. As these technologies evolve, you can expect more efficient, sustainable carbon-based products transforming industries and reducing ecological footprints.

Frequently Asked Questions

How Does Catalytic Carbon Enhance Chemical Reactions Differently Than Traditional Carbon?

Catalytic carbon enhances chemical reactions by providing a larger surface area, which allows reactants to interact more effectively. Unlike traditional carbon, it acts as a catalyst, speeding up reaction efficiency without being consumed. You’ll notice faster conversions and improved yields because the increased surface area allows for more active sites, making the process more effective and energy-efficient. This makes catalytic carbon especially valuable in industrial and environmental applications.

What Are the Cost Implications of Producing Catalytic Carbon Versus Traditional Carbon?

Producing catalytic carbon typically costs 20-30% more than traditional carbon, mainly due to its specialized manufacturing process. While this initial investment may seem high, it often pays off through improved efficiency and longer lifespan. Considering economic feasibility, catalytic carbon can reduce waste and energy consumption, positively impacting environmental impact. Over time, these benefits can offset higher production costs and make it a more sustainable choice.

Can Catalytic Carbon Replace Traditional Carbon in All Industrial Applications?

Catalytic carbon can’t replace traditional carbon in all industrial applications due to manufacturing challenges and environmental impact concerns. While it offers benefits like reduced emissions and improved efficiency, its production process is complex and costly. You should consider these factors carefully, as some industries may still rely on traditional carbon for cost-effectiveness and proven performance. Ultimately, a hybrid approach might be best, balancing environmental impact with practical manufacturing needs.

How Does the Lifespan of Catalytic Carbon Compare to That of Traditional Carbon?

You’ll find that catalytic carbon generally has a longer lifespan than traditional carbon, thanks to its enhanced durability comparison. This means you won’t need to replace it as often, reducing downtime and costs. Its higher replacement potential makes it a more sustainable choice in industrial applications. You’ll appreciate the durability and efficiency, which can lead to better performance and fewer interruptions in your processes over time.

Are There Any Health Risks Associated With Handling Catalytic Carbon Materials?

Handling catalytic carbon generally poses low health risks if you follow safety guidelines, but exposure concerns remain. Did you know that improper handling can lead to inhaling fine particles, which may irritate your lungs or cause long-term health issues? To stay safe, wear gloves and masks, and avoid inhaling dust. Proper handling minimizes toxicity risks, ensuring you stay healthy while benefiting from catalytic carbon’s advantages.

Conclusion

By understanding the differences between traditional and catalytic carbon, you can make smarter choices for your industry. Did you know catalytic carbon can reduce energy use by up to 30% compared to traditional methods? As technology advances, embracing these innovative materials not only boosts efficiency but also supports sustainability. Staying informed on these trends helps you stay ahead, ensuring your processes are both effective and eco-friendly. The future of carbon is transforming—are you ready to lead the change?