This guide simplifies bypass valves, showing how they control fluid flow, pressure, and system efficiency. It covers key industry uses, such as chemical processing and water treatment, and explains essential codes from ASME and other standards. You’ll learn about proper installation, maintenance, and inspection practices to guarantee safety and compliance. Staying updated on regulations is vital; keep exploring to master the complete picture of bypass valve management and compliance requirements.

Key Takeaways

- Bypass valves control fluid flow, pressure, and flow rate to ensure system safety and efficiency in industrial applications.

- ASME standards regulate material selection, design, testing, and certification for compliant bypass valve installation.

- Proper installation, routine inspection, and maintenance are vital for bypass valve reliability and safety compliance.

- Common compliance challenges include regional regulation differences and documentation; solutions involve certified professionals and updated procedures.

- Staying current with regulations requires monitoring official sources, training staff, and maintaining organized records of standards updates.

What Are Bypass Valves and How Do They Work?

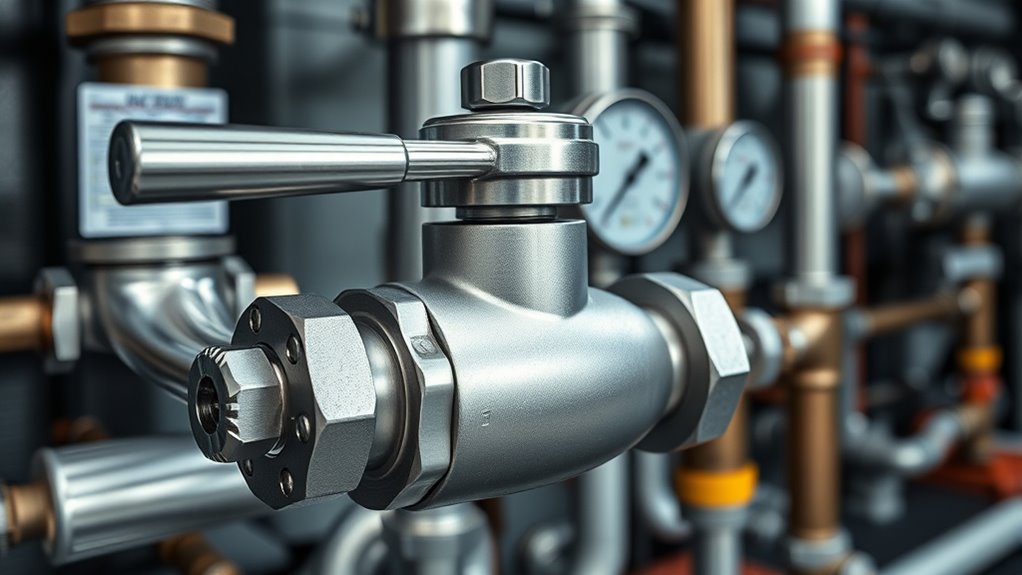

Bypass valves are specialized devices that control the flow of fluids within a system, allowing certain sections to be bypassed when necessary. They help manage pressure regulation by redirecting flow around equipment or sections that require maintenance or need to be protected from pressure surges. By adjusting the valve, you can control the flow rate, ensuring systems operate efficiently and safely. When pressure builds up or drops unexpectedly, the bypass valve opens or closes to maintain stable conditions, preventing damage or system failure. This flow control capability makes bypass valves essential for maintaining ideal system performance. Their ability to quickly divert flow helps keep processes running smoothly, especially during system fluctuations or repairs. Additionally, understanding the proper operation and safety protocols for bypass valves is crucial for effective system management.

Key Industries and Applications for Bypass Valves

Many industries rely on bypass valves to guarantee smooth and safe operations. In industrial automation, they help regulate flow and pressure, ensuring systems run efficiently without interruption. Bypass valves are essential in chemical processing, power generation, and oil and gas sectors, where continuous operation is critical. They allow for maintenance, testing, or emergency shutdowns without shutting down entire systems. Environmental considerations also play a key role, as bypass valves help prevent leaks and spills by controlling fluid paths carefully. In water treatment and HVAC systems, they improve safety and efficiency while minimizing environmental impact. Overall, these applications show how bypass valves support operational reliability, safety, and environmental responsibility across diverse industries. Incorporating juice detox principles, these valves contribute to maintaining system cleanliness and optimal operation.

Essential Codes and Standards Governing Bypass Valves

Understanding the essential codes and standards for bypass valves helps guarantee safety and proper performance. You need to be familiar with ASME standards, plumbing codes, and safety regulations that apply. These rules guide you in selecting, installing, and maintaining bypass valves correctly. Additionally, knowledge of angel numbers can provide insights into timing and opportunities for system upgrades or inspections.

ASME Standards Overview

Have you ever wondered which standards guarantee the safety and reliability of bypass valves? ASME standards set the foundation for ensuring quality through strict guidelines. Here’s what you should know:

- Material selection: ASME codes specify suitable materials to withstand pressure, temperature, and corrosion, influencing the valve’s durability.

- Design considerations: They guide engineers on proper design, ensuring valves can handle operational stresses while maintaining safety.

- Pressure and temperature ratings: Standards define acceptable limits, preventing failures caused by overpressure or extreme conditions.

- Testing and certification: ASME standards mandate rigorous testing procedures, confirming that valves meet safety and performance criteria before installation.

Following these standards helps you select and design bypass valves that are safe, reliable, and compliant.

Plumbing Code Requirements

Plumbing code requirements establish the essential standards that guarantee bypass valves are safe, reliable, and compliant with local regulations. These codes specify leak prevention measures and flow regulation standards to ensure proper operation. You must select valves that meet material and design standards outlined in your jurisdiction’s codes. Proper installation is critical to prevent leaks and ensure flow control. Check the following table for common requirements:

| Requirement | Description |

|---|---|

| Material Standards | Must meet durability and corrosion resistance standards |

| Leak Prevention | Use approved sealing and connection methods |

| Flow Regulation | Ensure valves provide accurate flow control |

Adhering to these codes helps you avoid violations and guarantees your bypass system functions safely and efficiently. Ensuring compliance with material standards and installation practices is essential for long-term performance.

Safety and Compliance Rules

Safety and compliance are essential when selecting and installing bypass valves, as they must meet specific codes and standards to guarantee reliable operation and protect your system. Following these regulations ensures hazard mitigation and quality assurance, reducing risks of failure or accidents. A thorough understanding of eye patch benefits can also aid in choosing the right type of eye patch for your needs. To stay compliant, you should: 1. Verify that the bypass valve adheres to local and industry standards like ASME or ISO. 2. Ensure proper certifications for safety and performance. 3. Regularly inspect and maintain valves to meet safety guidelines. 4. Document all compliance measures for audits and quality assurance. Adhering to these rules helps prevent hazards, improves system reliability, and guarantees your bypass valves operate safely and effectively within regulatory requirements.

Understanding Material and Design Requirements

Understanding the material and design requirements of bypass valves is essential for ensuring reliable operation and longevity. Material selection plays a critical role, as it affects corrosion resistance, durability, and compatibility with the system’s fluids. You should choose materials suited to your specific environment and pressure conditions. Design considerations also matter; the valve must handle flow rates efficiently, minimize pressure drops, and facilitate maintenance. Pay attention to the valve’s construction, including the seat and seal materials, to prevent leaks and ensure smooth operation over time. Properly designed bypass valves reduce failure risks and improve system performance. Additionally, considering fathers’ guidance can help in making informed choices about valve features and durability. By carefully evaluating these material and design factors, you ensure your bypass valve functions effectively, reduces downtime, and extends its service life.

Installation Best Practices and Safety Guidelines

Proper installation of bypass valves is key to guaranteeing their reliable operation and long service life. Follow these installation techniques and safety protocols to get it right:

- Ensure the valve is compatible with your system’s pressure and flow requirements before installation.

- Use proper tools and torque specifications to avoid damaging components.

- Secure all connections tightly to prevent leaks, but avoid over-tightening.

- Always wear personal protective equipment and follow safety protocols to prevent accidents during installation.

- Consult manufacturers’ guidelines to ensure compliance with industry standards and to verify proper installation procedures.

Inspection, Testing, and Maintenance Protocols

Regular inspection of bypass valves is essential to guarantee they function correctly and prevent failures. You should follow established maintenance and testing standards to keep the valves in prime condition. Staying diligent with these protocols helps maintain safety and system reliability. Additionally, implementing routine checks can detect early signs of wear or damage, further preventing potential malfunctions.

Routine Inspection Procedures

Routine inspection of bypass valves is crucial to guarantee they function correctly and maintain system safety. Regular checks ensure proper pressure regulation and fluid control, preventing system failures. During inspections, focus on identifying leaks, corrosion, or wear that could impair performance. Confirm that the valve moves freely and seats properly. Also, verify that the actuator responds correctly to control signals. Additionally, understanding valve technology can help in diagnosing issues more effectively and selecting appropriate maintenance procedures. Consider these steps:

- Visually inspect for signs of damage or corrosion.

- Test valve operation by manually opening and closing.

- Check for leaks around seals and connections.

- Ensure pressure regulation settings are accurate and functioning.

Performing these inspections keeps your bypass valves reliable, supporting system safety and compliance. Proper routine checks help catch issues early, avoiding costly repairs or failures down the line.

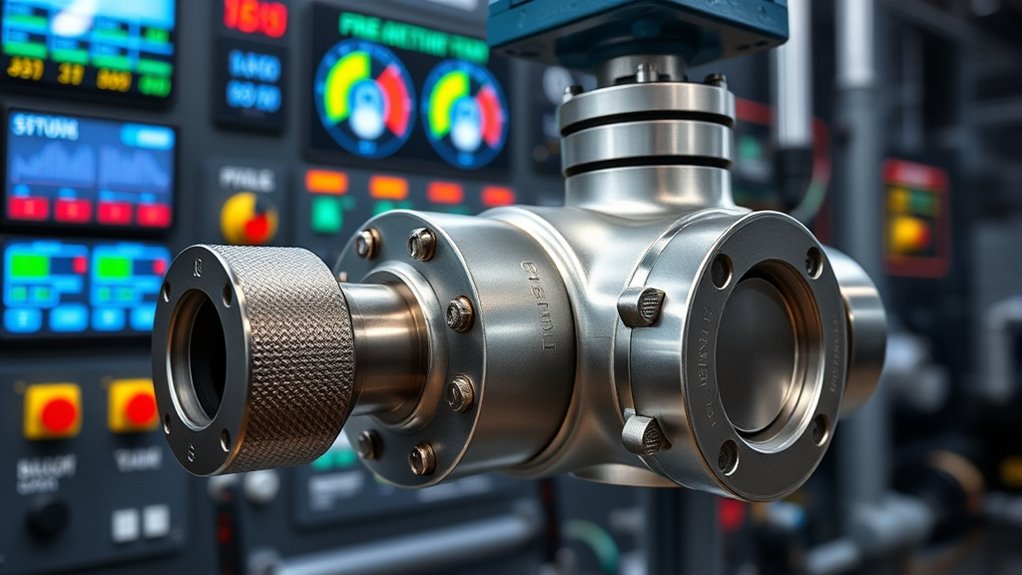

Maintenance and Testing Standards

Maintaining bypass valves according to established standards guarantees they operate safely and effectively over time. Regular valve calibration ensures the valve’s performance remains accurate, preventing malfunctions. You should perform periodic leak detection to identify any signs of leakage, which could compromise safety or efficiency. Follow manufacturer guidelines and industry codes to schedule inspections, testing, and maintenance routines. Testing should include verifying valve operation under various conditions and ensuring all components function correctly. Proper documentation of maintenance activities helps track valve performance and compliance. By adhering to these standards, you minimize downtime, extend the lifespan of your bypass valves, and ensure they meet safety and regulatory requirements. Consistent maintenance and testing are essential for reliable, safe operation in your system.

Common Compliance Challenges and How to Address Them

Understanding compliance standards for bypass valves can be challenging because regulations often change and vary by region. You may face regulatory hurdles like differing regional codes, complex documentation requirements, and evolving standards. To address these challenges, consider these steps:

- Stay informed about regional regulations through official sources.

- Maintain meticulous documentation of valve specifications, testing, and installation procedures.

- Work with certified professionals familiar with local compliance standards.

- Regularly review and update your procedures to adapt to new regulations.

- Incorporate Bedroom design principles to create a safe and compliant environment for equipment installation and maintenance.

Staying Up-To-Date With Regulatory Changes

Staying up-to-date with regulatory changes is essential to guarantee your bypass valves remain compliant and operate safely. Regulatory updates can impact your compliance strategies, so staying informed helps you avoid penalties and ensures safety standards are met. Regularly check industry notices, official agency websites, and subscribe to alerts. Implement a tracking system for new codes and amendments to streamline updates. Consider training staff on evolving standards to maintain compliance. Use this table to help stay organized:

| Regulatory Update Sources | Key Actions |

|---|---|

| Official agency websites | Monitor for new regulations |

| Industry alerts | Update compliance strategies |

| Training programs | Educate staff on changes |

Frequently Asked Questions

How Do Bypass Valves Impact Overall System Efficiency?

Bypass valves improve your system performance by allowing you to redirect flow during maintenance procedures, reducing downtime. They help maintain efficiency by isolating sections that need repairs without shutting down the entire system. Properly managing bypass valves ensures smooth operation and prevents pressure imbalances, which can cause damage. Regular maintenance of these valves keeps them functioning correctly, ultimately enhancing overall system efficiency and extending equipment lifespan.

Are There Specific Certifications Required for Bypass Valve Manufacturers?

Yes, bypass valve manufacturers need to meet specific manufacturing standards and obtain quality certifications. These certifications, like ISO 9001 or ASME standards, ensure their products are reliable and compliant with industry regulations. You should verify that the manufacturer holds these certifications, as they demonstrate adherence to rigorous quality controls and safety protocols, giving you confidence in the valve’s performance and longevity in your system.

What Are the Common Penalties for Non-Compliance?

You face significant penalties if you don’t comply with bypass valve regulations. Penalties overview includes hefty fines, product recalls, and potential shutdowns, all enforced through compliance enforcement agencies. These authorities actively monitor manufacturers and suppliers, so non-compliance can lead to legal actions and damage to your reputation. To avoid these consequences, guarantee your bypass valves meet all regulatory standards and maintain thorough documentation to demonstrate compliance at all times.

How Can I Verify a Bypass Valve’s Compliance Documentation?

Did you know over 60% of bypass valve failures are due to improper documentation? To verify compliance documentation, first check that it meets installation standards and includes recent maintenance procedures. Confirm the paperwork is from a certified manufacturer and review it for valid certifications like ISO or UL. Cross-reference the documentation with the latest industry regulations, and don’t hesitate to contact the supplier for clarification if needed.

What Training Is Recommended for Personnel Handling Bypass Valve Installation?

You should pursue specialized training on installation procedures and safety protocols for bypass valves. Look for courses offered by manufacturers, industry organizations, or certified technical schools that focus on proper installation techniques, safety measures, and compliance standards. Hands-on practice combined with theoretical knowledge guarantees you understand how to install bypass valves correctly and safely, reducing risks and ensuring efficient operation. Continuous education helps you stay updated on evolving codes and best practices.

Conclusion

Bypass valves may seem straightforward, but their compliance demands a nuanced understanding of standards and best practices. Staying informed ensures you navigate regulations smoothly, preventing costly mistakes. As industry standards evolve, so should your knowledge—sometimes, the key to seamless operation lies in recognizing the subtle overlaps between design, safety, and regulation. When you align these elements, compliance becomes less of a hurdle and more of a natural outcome, almost as if the right protocols were guiding your every step.