When sizing your spin-down filter, you need to match the mesh rating to your flow rate to guarantee effective debris removal without causing excessive pressure drop. Finer meshes capture smaller particles but increase flow resistance, while coarser meshes let flow pass more easily but may miss debris. Balancing these factors helps you maintain system efficiency and durability. Keep in mind, choosing the right mesh based on your flow needs ensures ideal performance—learn more to get it just right.

Key Takeaways

- Mesh ratings determine debris capture efficiency and flow resistance, impacting how well the filter performs at specific flow rates.

- Higher flow rates require coarser mesh to prevent excessive pressure drops and system strain.

- Proper sizing balances mesh rating with flow rate to optimize debris removal without impairing system performance.

- Pressure drop charts help match mesh ratings to flow demands, ensuring longevity and efficiency.

- Selecting the right mesh rating based on flow rate maintains system durability and effective filtration.

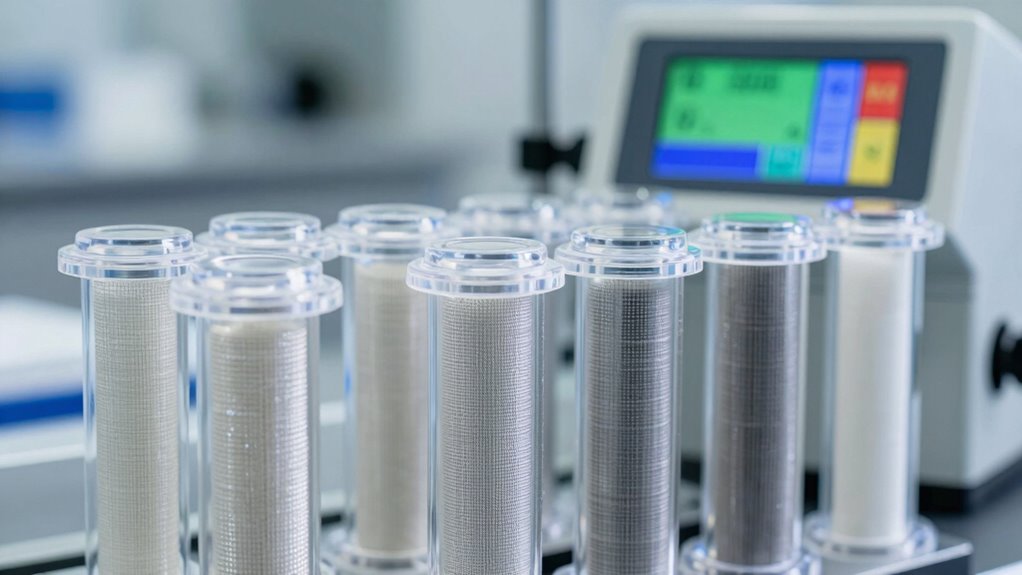

Have you ever wondered how to determine the right size of a spin-down filter for your system? Choosing the correct filter size isn’t just about fitting it into your setup; it’s about ensuring ideal performance and longevity. To do this effectively, you need to understand how the filter material and flow rate interact. The filter material, which can range from stainless steel mesh to various types of woven fabrics, directly influences how much debris the filter can trap and how it affects your system’s pressure drop. A finer mesh captures smaller particles but also creates more resistance to flow, leading to a higher pressure drop across the filter. Conversely, a coarser mesh allows more flow with less resistance but might not effectively remove all contaminants. Balancing these factors is key to selecting the right filter material that meets your system’s needs without causing unnecessary pressure loss.

When sizing a spin-down filter, considering the pressure drop is critical. Pressure drop refers to the resistance the filter introduces into your system, impacting how efficiently your pump can circulate fluid. If the pressure drop is too high, your pump works harder, increasing energy costs and potentially reducing equipment lifespan. Conversely, a filter with a very low pressure drop might not catch enough debris, risking contamination downstream. To properly size your filter, you need to evaluate your system’s flow rate and how different mesh ratings influence pressure drop. Most manufacturers provide pressure drop charts or guidelines based on flow rates and mesh sizes, which can help you make an informed decision. Selecting a filter with an appropriate mesh rating ensures that the pressure drop remains within acceptable limits, preserving system efficiency and preventing unnecessary wear. Additionally, understanding the importance of flow rate helps in selecting a filter that balances debris removal with maintaining optimal system performance. Remember, the goal isn’t just to filter out contaminants but to do so without compromising your system’s performance. This means selecting a filter material and mesh rating that align with your flow demands and pressure drop tolerances.

Frequently Asked Questions

How Do Temperature Variations Affect Filter Mesh Ratings?

Temperature variations can impact filter mesh ratings by affecting temperature stability and causing material expansion. As temperatures rise, the mesh may expand, potentially reducing its pore size and filtration efficiency. Conversely, cooler temperatures help maintain stable mesh dimensions. You should consider these effects when selecting filters, ensuring materials with good temperature stability to prevent performance issues caused by expansion or contraction, especially in fluctuating environments.

Can Filter Size Impact Long-Term System Efficiency?

Imagine your system facing unexpected filter clogging that slows everything down. Yes, filter size can markedly impact long-term efficiency, especially if it’s too small or too large for your flow needs. Choosing the right size helps reduce maintenance, prevents blockages, and maintains ideal flow. Neglecting this can lead to frequent replacements and system downtime, jeopardizing your operation’s performance over time. Stay proactive—select the right filter size today.

Are There Industry Standards for Spin-Down Filter Sizing?

Yes, industry standards guide spin-down filter sizing to guarantee ideal filtration efficiency and ease of maintenance. You should consider flow rate, debris load, and system specifications when selecting filter sizes. Proper sizing helps maintain consistent performance, reduces maintenance frequency, and prevents system downtime. Following these standards ensures your filtration system operates effectively, extending its lifespan while keeping your system clean and efficient.

How Often Should Filters Be Replaced Based on Flow Rate?

You should replace your filters based on their flow rate and filter lifespan, which typically ranges from every few months to a year. If you notice a drop in flow rate or increased pressure, it’s a sign to replace them sooner. Regularly monitoring these indicators helps maintain peak performance and prevents clogging. Following manufacturer recommendations ensures your filters work efficiently and extend their replacement frequency effectively.

What Materials Are Best for High-Flow Filtration Systems?

For high-flow filtration systems, prioritize materials that offer excellent material compatibility and corrosion resistance. Stainless steel and certain plastics like polypropylene or PVDF are ideal, as they withstand harsh chemicals and high pressures. These materials guarantee durability and maintain flow efficiency. By selecting corrosion-resistant, compatible materials, you reduce maintenance needs and extend filter lifespan, keeping your system running smoothly even under demanding high-flow conditions.

Conclusion

Think of choosing the right spin-down filter size like fitting a key to a lock—you need a perfect match to guarantee smooth operation. By understanding how mesh ratings relate to flow rates, you can prevent clogs and maintain ideal performance. It’s all about finding that sweet spot where your system flows freely without overwhelming the filter. So, take your time, measure carefully, and let your filter be the key that keeps everything running seamlessly.