If you’re looking for the best low pressure drop flex connectors for smooth fluid flow in 2025, I recommend considering options like the Sigma Electric ProConnex Flex 90-Degree Squeeze Connector, Arlington’s 90-degree flex connector, and versatile fittings like hose adapters and heat-shrink butt connectors. These prioritize durable materials, precise sizing, minimal internal bends, and safety standards. Keep exploring further, and I’ll share detailed insights to help you select the right connectors for your needs.

Key Takeaways

- High-quality materials like aluminum and zinc die-cast ensure low internal turbulence and corrosion resistance for optimal flow.

- Connectors with smooth internal surfaces and gentle bends minimize turbulence and pressure drops during fluid transfer.

- Proper sizing and compatibility with standard thread types prevent leaks and ensure secure, low-resistance connections.

- Low-pressure drop connectors are rated for high flow rates and pressures, maintaining system efficiency in various applications.

- Certifications such as UL and CSA guarantee safety, durability, and reliable performance in demanding environments.

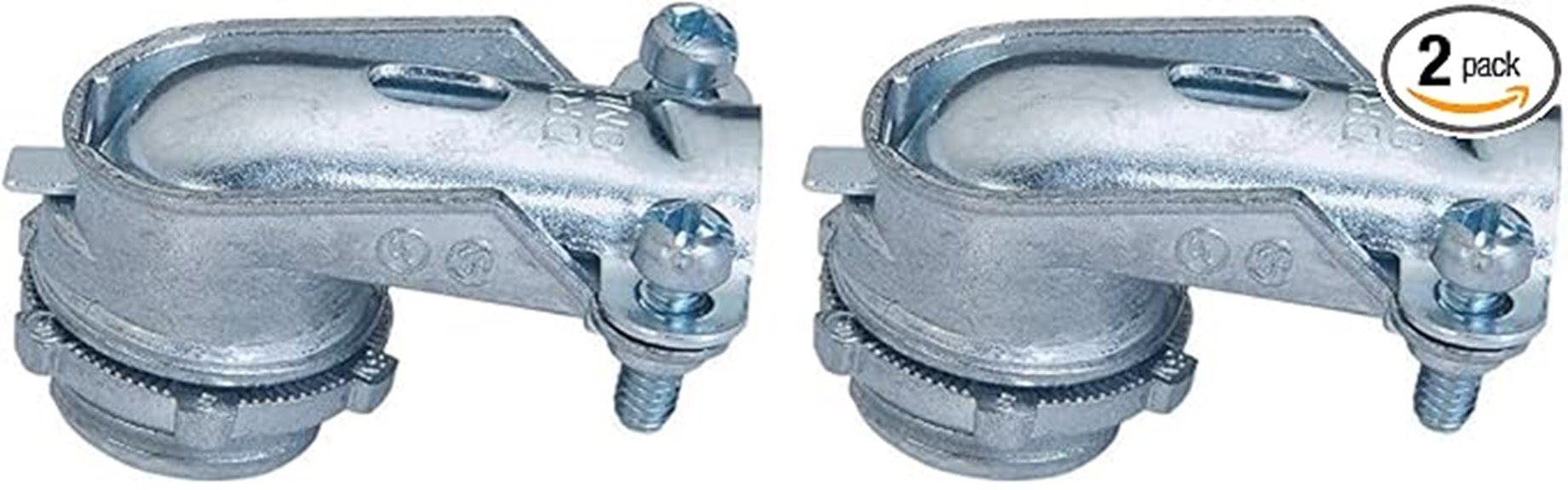

Sigma Electric ProConnex Flex 90-Degree Squeeze Connector (2-Pack)

If you’re looking for a reliable, low-pressure drop connector for your electrical conduit needs, the Sigma Electric ProConnex Flex 90-Degree Squeeze Connector is an excellent choice. This set of two connectors features a durable aluminum body with a zinc die-cast exterior finish, ensuring long-lasting performance. Designed to connect FMC or RWFMC to a 1-inch knockout, it’s compatible with both aluminum and steel conduits. The compression-type fitting provides a secure, tight seal, reducing pressure loss. Certified by UL and CSA, it offers peace of mind for safety and compliance. Its compact size and easy squeeze mechanism make installation straightforward, enhancing your wiring efficiency.

Best For: electricians and electrical contractors seeking a durable, reliable connector for terminating FMC or RWFMC conduits to 1-inch knockouts in residential or commercial wiring projects.

Pros:

- Made from durable aluminum with a zinc die-cast exterior finish for long-lasting performance

- UL and CSA listed, ensuring safety and compliance standards are met

- Easy to install with a squeeze mechanism, saving time and effort during wiring tasks

Cons:

- Only suitable for 1-inch conduit sizes, limiting its application to specific projects

- Discontinued status may affect future availability or support

- Very lightweight at 0.02 ounces, which could be a concern for handling or durability in some environments

Nilight 200PCS Heat Shrink Butt Connectors Kit

The Nilight 200PCS Heat Shrink Butt Connectors Kit stands out as an excellent choice for anyone needing reliable, waterproof wire splicing solutions. Made with high-quality polyamide outer covers and red copper inner tubes, these connectors withstand high temperatures and guarantee efficient current flow. The waterproof nylon hot-melt adhesive with gel offers superb protection against moisture, making them perfect for marine and automotive use. With three sizes—covering 22 AWG to 10 AWG wires—and color-coded tubing for easy identification, they simplify installation. This kit provides durable, secure connections that minimize voltage drops and prevent wiring failures, ensuring long-lasting performance in demanding environments.

Best For: DIY enthusiasts, automotive and marine electricians seeking durable, waterproof wire splicing connectors for high-temperature environments.

Pros:

- Made with high-quality polyamide outer cover and red copper inner tube for durability and efficient current flow

- Waterproof nylon hot-melt adhesive with gel provides excellent protection against moisture and water ingress

- Color-coded tubing with wire gauge imprint simplifies size identification and installation

Cons:

- Limited to specific wire gauge sizes (22-10 AWG), which may not suit all wiring projects

- The kit’s bulk packaging may be excessive for small or occasional repairs

- Requires proper heat shrinking tools and techniques for optimal sealing and insulation

ARLINGTON 852 90 Degree Flex Connector for Aluminum and Steel

The ARLINGTON 852 90 Degree Flex Connector is an excellent choice for electrical installations requiring a secure, corrosion-resistant connection in aluminum or steel flex cables. Made from durable zinc die-cast material, it features two screws and a locknut for a tight, concrete-tight fit when tapped into a 1/2-inch knockout. It fits cable diameters from 0.770 to 1.205 inches and is designed for use with a 3/4-inch trade size opening. Its compact dimensions—2.380 inches high and 2.025 inches wide—ensure easy installation and reliable performance in various conduit applications. This connector combines durability with a low-profile design, making it ideal for seamless fluid flow and electrical safety.

Best For: contractors and electricians seeking a durable, corrosion-resistant flex connector for aluminum and steel conduit installations.

Pros:

- Made from durable zinc die-cast material for corrosion resistance and longevity

- Secure, concrete-tight fit with two screws and locknut for safety and reliability

- Compatible with cable diameters from 0.770 to 1.205 inches and fits 3/4-inch knockout openings

Cons:

- Limited to specific cable sizes and may require precise measurement for proper fit

- Relatively heavy for its size at 0.184 pounds, which could impact installation ease in large quantities

- May require tapping into the knockout for secure installation, adding a step to the process

Pressure Washer Hose 100 FT x 1/4, Kink Resistant Extension Hose

Looking for a reliable extension hose that won’t kink or kink-resistant? The Pressure Washer Hose 100 FT x 1/4 offers just that. Made from high-tech, flexible polyurethane with protective sleeves, it resists bending damage and lasts longer. Rated up to 4000 PSI, it’s perfect for cleaning cars, driveways, and more. It fits most brands with standard M22 fittings and includes quick connect adapters for easy setup. Its non-marking surface cleans effectively without scratching surfaces. Plus, with 7×24 support and a warranty, I feel confident in its durability and performance, making my pressure washing tasks smoother and more efficient.

Best For: homeowners and professionals seeking a durable, kink-resistant extension hose for high-pressure cleaning tasks on various surfaces.

Pros:

- Made from high-tech, flexible polyurethane for added kink resistance and durability

- Rated up to 4000 PSI, suitable for a wide range of cleaning applications

- Includes quick connect fittings and adapters for easy installation and versatility

Cons:

- May be heavier or bulkier than standard hoses due to high durability materials

- Requires compatible fittings; incompatible pressure washers may need adapters

- The length of 100 FT might be cumbersome for storage and maneuverability in tight spaces

Hose Adapter Reducer Fitting Connector

A Hose Adapter Reducer Fitting Connector is an ideal choice for those seeking reliable size conversions with minimal pressure loss. Made of lightweight yet sturdy aluminum, it resists wear and corrosion, ensuring long-term durability. Its deep, external threads prevent deformation and dust buildup, while rubber gaskets provide a reliable seal against leaks and contaminants. Available in two styles—1/2-28 and 5/8-24 female ends—it can convert to various male thread sizes like 3/4-16 and 13/16-16, offering versatile compatibility. Each set includes the connector and gaskets, and customer support is responsive within 24 hours, making it a dependable adapter for seamless fluid flow.

Best For: DIY enthusiasts, plumbers, and maintenance professionals seeking durable, reliable hose adapters for seamless size conversions and leak-free connections.

Pros:

- Made of lightweight aluminum that is sturdy and resistant to wear and rust

- Deep, external threaded design prevents deformation and dust buildup

- Includes rubber gaskets for reliable sealing and leak prevention

Cons:

- Size compatibility requires careful measurement to ensure proper fit

- May need additional adapters for certain applications outside specified sizes

- Limited to specific thread sizes, which might not suit all hose types

Kalolary 10PCS Barbed Tee for Irrigation Tubing

Kalolary’s 10PCS Barbed Tee fittings excel in creating secure, leak-free connections for irrigation systems, especially when maintaining low pressure drop is essential. These fittings are compatible with 1/2 inch tubing and 1/4 inch drip lines, making them versatile for various setups. Made from durable, recycled plastic with increased wall thickness, they withstand pressures up to 45 PSI. Installation is simple—press the barb into tubing, sometimes warming the tube for better fit, then secure with screw caps. They efficiently divide a single line into multiple zones, ensuring consistent watering for gardens, greenhouses, or farms. Overall, they’re a reliable choice for expanding irrigation systems seamlessly.

Best For: DIY gardeners, professional landscapers, and farmers seeking durable, easy-to-install irrigation fittings for expanding or maintaining their watering systems.

Pros:

- Made from high-quality recycled plastic with increased wall thickness for durability and long-term use.

- Compatible with most 1/2 inch tubing and 1/4 inch drip lines, offering versatile connection options.

- Easy to install by pressing or warming tubing, creating secure, leak-free connections suitable for various irrigation setups.

Cons:

- Some users may find the initial manipulation of fittings difficult until tubing is warmed for better flexibility.

- Not included are water pressure regulators or automatic timers, which are recommended for optimal system performance.

- The fittings may require careful handling to prevent damage during installation or adjustments.

Factors to Consider When Choosing Low Pressure Drop Flex Connectors

When selecting low pressure drop flex connectors, I focus on key factors like material quality, internal bends, and connector size to guarantee optimal performance. It’s important to take into account flow rate compatibility and how easy the connectors are to install and maintain. These points help me choose the right connectors that balance efficiency and durability for my needs.

Material Quality and Coating

Choosing the right low pressure drop flex connector starts with prioritizing material quality and coating. High-quality materials like aluminum or zinc die-cast ensure durability and resistance to corrosion, helping the connector maintain its integrity over time. Proper coatings, such as zinc plating or corrosion-resistant paint, further protect against environmental factors and reduce friction losses. The material choice directly influences the internal surface smoothness, minimizing turbulence and pressure drops during fluid flow. Precise manufacturing tolerances are essential—high-quality materials help reduce internal gaps and irregularities that cause flow resistance. Investing in connectors with robust, corrosion-resistant coatings and durable materials guarantees long-term performance, especially in demanding environments like marine or outdoor settings. This focus on quality ensures efficient, seamless fluid flow with minimal pressure loss.

Internal Bends and Angles

Internal bends and angles play a crucial role in the performance of low pressure drop flex connectors, as they directly impact flow resistance. Sharp or tight angles create turbulence, which hampers fluid movement and increases pressure drops. To keep flow efficient, smooth, gradual bends are essential—they minimize disruptions and help maintain a low pressure drop level. The number and degree of these bends matter: more or sharper angles lead to greater pressure loss. Properly designed flex connectors feature minimal internal angles, promoting better fluid dynamics and pressure stability throughout the system. When selecting connectors, prioritize those with gentle curves and fewer internal bends. This ensures ideal flow performance, reduces energy consumption, and supports the seamless operation of your fluid systems in 2025.

Connector Size and Fit

Proper connector size and fit are essential for maintaining low pressure drops in flex connectors. I always double-check that the connector’s diameter matches my pipes or conduits, typically measured in inches or millimeters, to guarantee a secure fit and seal. Verifying the thread type, like NPT or BSP, is vital for compatibility with existing fittings, preventing leaks and unnecessary pressure loss. I choose connectors with precise threading and high-quality manufacturing to minimize gaps and resistance. Additionally, I look for connectors with smooth internal surfaces and minimal obstructions, which promote unobstructed flow. Matching the connector’s size and specifications to my system’s flow requirements helps optimize pressure retention and operational efficiency, making sure the system runs smoothly with minimal pressure drop.

Flow Rate and Compatibility

Have you ever experienced pressure drops or flow issues after installing a flex connector? If so, it’s likely due to choosing a connector that doesn’t match your system’s flow requirements or isn’t compatible with your pipes. To prevent this, verify the connector is rated for your specific flow rate to avoid restrictions that cause pressure loss. Check that it fits your pipe or conduit sizes, like NPT threads, to maintain smooth flow without turbulence. Opt for connectors made from materials with smooth internal surfaces, such as aluminum or zinc die-cast, to reduce flow resistance. Additionally, select a low-profile or streamlined design to minimize turbulence. Always confirm that the connector can handle your system’s maximum operating pressure to prevent flow restrictions or deformation, keeping your system efficient and reliable.

Installation and Maintenance

When selecting low pressure drop flex connectors, it’s crucial to guarantee compatibility with your pipe or cable sizes from the start. Check that the installation fittings match the connector’s threading and diameter specifications to ensure a secure fit. Properly securing all connections with the recommended tools prevents leaks and disconnections that can increase pressure drop. Regular inspection and maintenance are essential, especially in environments exposed to moisture or chemicals, to detect corrosion, damage, or wear early. Using connectors with smooth internal surfaces and minimal fittings helps reduce turbulence and resistance. Always follow the manufacturer’s guidelines for installation torque and maintenance schedules. Doing so preserves the connector’s integrity and maintains ideal flow, ensuring your system stays efficient and reliable over time.

Frequently Asked Questions

How Do Flex Connectors Impact Overall System Efficiency?

Flex connectors considerably boost system efficiency by reducing pressure drops and absorbing vibrations, which minimizes wear and tear on pipes. I’ve seen how they improve fluid flow stability and decrease maintenance needs. When I use high-quality flex connectors, I notice smoother operation and less energy consumption. Overall, they’re a smart investment that helps keep systems running efficiently, saving time and costs in the long run.

Are Low Pressure Drop Connectors Suitable for High-Temperature Applications?

Yes, low pressure drop connectors can be suitable for high-temperature applications, but it depends on their materials. Imagine a flexible, heat-resistant tube that bends effortlessly under intense conditions without sacrificing flow efficiency. I’ve seen these connectors withstand extreme temperatures while maintaining low pressure drops, making them ideal for demanding environments. Just guarantee you choose ones with proper thermal ratings and compatibility to avoid any system failures.

What Maintenance Is Required for Long-Term Performance?

To guarantee long-term performance, I regularly inspect my flex connectors for signs of wear, corrosion, or leaks. I also clean them gently to prevent debris buildup and check fittings to make certain they’re secure. Replacing worn or damaged connectors promptly helps maintain peak fluid flow. Following the manufacturer’s maintenance guidelines is vital, and I keep records of inspections and replacements to track their condition over time.

Can Flexible Connectors Accommodate Thermal Expansion?

Did you know that flexible connectors can typically accommodate thermal expansion of up to 2 inches? Yes, they’re designed to handle thermal movements effectively. I’ve seen these connectors expand and contract with temperature changes without losing integrity or causing leaks. They’re ideal for systems where temperature fluctuations are common, ensuring seamless fluid flow. Using the right flexible connector helps protect your system and reduces maintenance costs over time.

How Do Installation Techniques Influence Pressure Drop?

Installation techniques greatly influence pressure drop because proper alignment minimizes turbulence and flow resistance. I guarantee flexible connectors are installed with adequate support and avoid overstretching or twisting, which can cause additional friction. Using correct fittings and securing connectors properly help maintain a smooth flow path. When I pay attention to these details, I notice a significant reduction in pressure loss, leading to more efficient and reliable fluid systems.

Conclusion

Think of these flex connectors as the gentle rivers guiding water seamlessly through a landscape. When chosen wisely, they guarantee smooth, uninterrupted flow, like a calm stream winding effortlessly around rocks. In 2025, selecting the right low pressure drop connector is like planting a clear path for fluid to travel without resistance. Trust these options to keep your system flowing effortlessly, just as a well-tuned river keeps its course true and steady.